Forging technology of Hastelloy C-276

A C-276, Hastelloy technology, applied in the field of metal forging technology, can solve problems such as affecting the production progress and yield of materials, reducing material thermoplasticity, and small forging temperature window, so as to improve production and processing efficiency, eliminate forging cracking, The effect of saving forging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The forging process of the Hastelloy C-276 is specifically as follows.

[0024] (1) Hastelloy C-276 electroslag casting ingot, the size is Φ300×500mm, the composition is (wt): Fe 5.32%, Cr16.23%, Mo 16.45%, W 3.83%, Mn 0.53%, C 0.008% , Si 0.03%, P 0.004%, S 0.003%, and the balance is Ni.

[0025] (2) First, heat treat Hastelloy C-276. The original temperature of the heating furnace is 36°C. Set the program to raise the temperature to 1000°C at a heating rate of 300°C / h and keep it for 1 hour; then raise the temperature to 100°C / h. 1100°C, keep warm for 15 hours, and air cool after taking out the oven. Before forging, put the Hastelloy C-276 into the heating furnace in front of the forging press for heating, raise the temperature to 1000℃ at a heating rate of 300℃ / s, and keep it for 1h; then raise it to 1150℃ at a heating rate of 100℃ / s, and keep it Start forging after 5h.

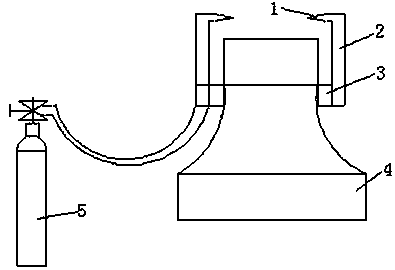

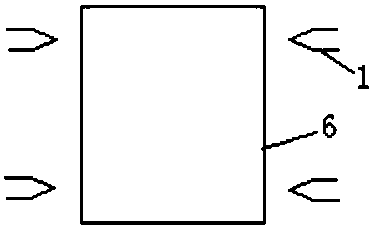

[0026] (3) Turn on the temperature replenishing device during forging, and spra...

Embodiment 2

[0028] Example 2: The forging process of the Hastelloy C-276 is as follows.

[0029] (1) Cast Hastelloy C-276, size 150×150×300mm, composition (wt): Fe 5.49%, Cr 15.88%, Mo 15.85%, W 3.73%, Mn 0.50%, C 0.006% , Si 0.05%, P 0.005%, S 0.005%, and the balance is Ni.

[0030] (2) Use a heating furnace to heat-treat the material. The original temperature of the heating furnace is 53°C. Set the program to raise the temperature to 990°C at a heating rate of 250°C / h and keep it for 1.5h; then raise the temperature to 1110°C at 80°C / h , keep warm for 15.5 hours, take out the oven and air cool. Before forging, put the Hastelloy C-276 into the heating furnace before the forging press for heating, raise the temperature to 1010°C at a heating rate of 200°C / s, and keep it for 1.2h; then raise the temperature to 1160°C at a heating rate of 90°C / s, Start forging after 5.5 hours of heat preservation.

[0031] (3) Turn on the temperature replenishing device during forging, spray nozzles from...

Embodiment 3

[0033]Embodiment 3: The forging process of the Hastelloy C-276 is as follows.

[0034] (1) As-cast Hastelloy C-276, the billet size is 150×150×260mm, the composition is (wt): Fe 5.69%, Cr16.03%, Mo 16.12%, W 3.92%, Mn 0.55%, C 0.008 %, Si 0.06%, P 0.004%, S 0.003%, and the balance is Ni.

[0035] (2) Use a heating furnace to heat-treat the material. The original temperature of the heating furnace is 73°C. Set the program to raise the temperature to 1010°C at a heating rate of 200°C / h and keep it for 1.2h; then raise the temperature to 1080°C at 90°C / h , keep warm for 16 hours, take out the oven and air cool. Before forging, put the Hastelloy C-276 into the heating furnace before the forging press for heating, raise the temperature to 1020°C at a heating rate of 250°C / s, and keep it for 1.3h; then raise the temperature to 1155°C at a heating rate of 80°C / s, Start forging after 6 hours of heat preservation.

[0036] (3) Turn on the temperature compensation device during forgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com