Welding method for stainless steel clad plates

A welding method and composite plate technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of weak welding at the joint, cracks at the joint, and affecting the quality of the joint, so as to achieve good economic benefits and prevent brittleness. The effects of softening or producing cracks and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

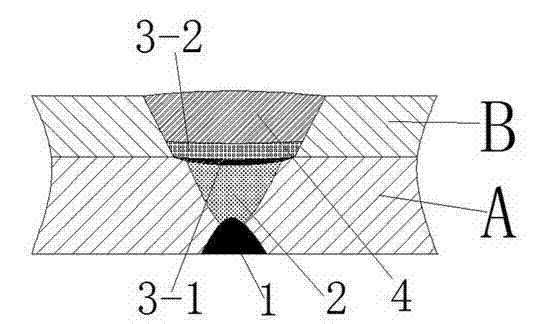

[0020] Such as figure 1 As shown, the stainless steel clad plate is divided into base layer A and clad layer B. First, the welding end face of the stainless steel clad plate is processed into a V-shaped groove shape, and the base layer A is welded by manual gas shielded welding. In the present invention, the welding seam of the base layer A is divided into a base layer 1 and a filling layer 2, and the welding is performed in the order of the base layer 1 and the filling layer 2. Adopt the 136 welding method, adjust the welding process specification parameters in place, use TWE-711Ni welding material, diameter φ1.4㎜ welding wire, DCEP polarity, adjust the current to 280~350A, voltage 32~35V, wire feeder speed is 25~35cm / min, gas flow rate 18~25L / min, start welding, in order to make the weld beautiful and full, the thickness of the weld seam base layer 1 is 0~2mm higher than the base layer A, after the welding is completed, remove the weld scar burr, the back Clean the root of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com