Method and apparatus for preparing composite solder for welding particle enhanced aluminium-based composite material

A particle-reinforced aluminum and composite material technology, applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problems of incomplete wetting of the reinforcement phase/matrix, microscopic segregation of the reinforcement phase, etc., to avoid corrosion and loss, Improve distribution and avoid particle agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples describe the present invention in more detail:

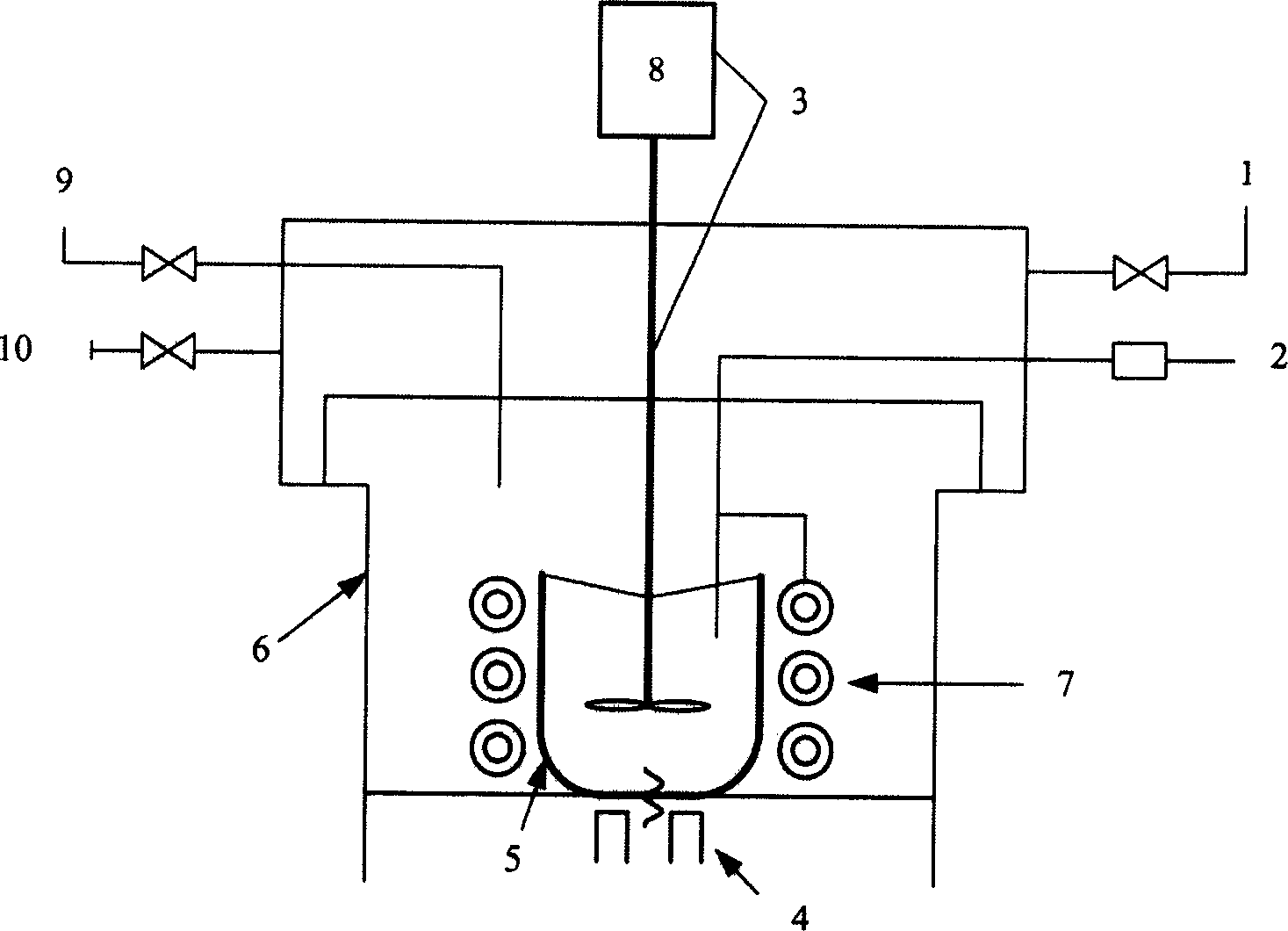

[0021] In conjunction with the accompanying drawings, the composition of the special equipment for the preparation method of the composite solder for particle reinforced aluminum matrix composite welding of the present invention includes a vacuum device 1, a heating temperature controller 2, a mechanical stirring device 3 and an ultrasonic vibration device 4, a crucible 5 is placed in a housing 6 provided with a vacuum pumping device. The crucible has a high-frequency induction heating coil 7 outside, and the high-frequency induction heating coil is connected to the heating controller 2. A mechanical stirring device is arranged in the crucible, and the transmission of the mechanical stirring device The rod protrudes from the housing and is connected with the motor 8. The lower part of the housing is equipped with an ultrasonic vibration device 4, and the housing is connected with a protective gas fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com