Welding method and device for ear loops of non-woven tapered mask

A technology for non-woven fabrics and masks, which is applied in the field of welding methods and devices for non-woven conical mask earbands, can solve the problems of short welding time, incomplete melting, affecting the quality of masks, etc., and achieves good welding use and good welding fixation. , the effect of easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

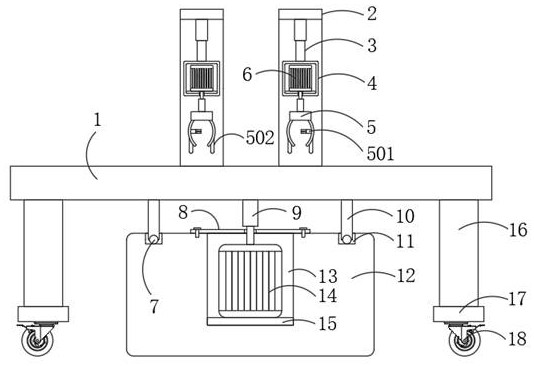

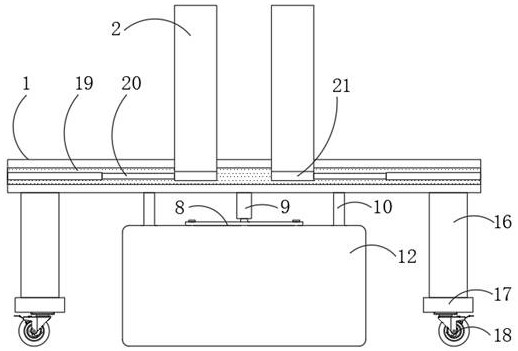

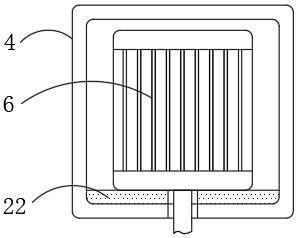

[0029] refer to Figure 1-4 : The device for welding the earbands of non-woven tapered masks, including a conveying device 1, the conveying device 1 is provided with a conveying belt for conveying and processing the masks, and the outer surfaces of the front and rear sides of the conveying device 1 are provided along the horizontal direction. There are elongated chutes 19, and elongated chutes 19 are set up so that the slide plate 21 can slide stably inside the elongated chutes 19, and the inner surface walls on both sides of the two elongated chutes 19 are equipped with driving mechanisms 20 , the driving mechanism 20 is used for driving and extending, and its driving mechanism 20 is an existing technology, and the driving mechanism 20 is elongated, thereby causing the slide plate 21 to slide inside the elongated chute 19, and the driving mechanism 20 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com