Modified graphene/epoxy resin composite material and preparation method thereof

A technology of epoxy resin and composite materials, which is applied in the field of modified graphene/epoxy resin composite materials and its preparation, can solve problems such as poor dispersion, easy agglomeration, and poor resin compatibility, and achieve improved interfacial bonding performance and improved Reaction temperature, the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

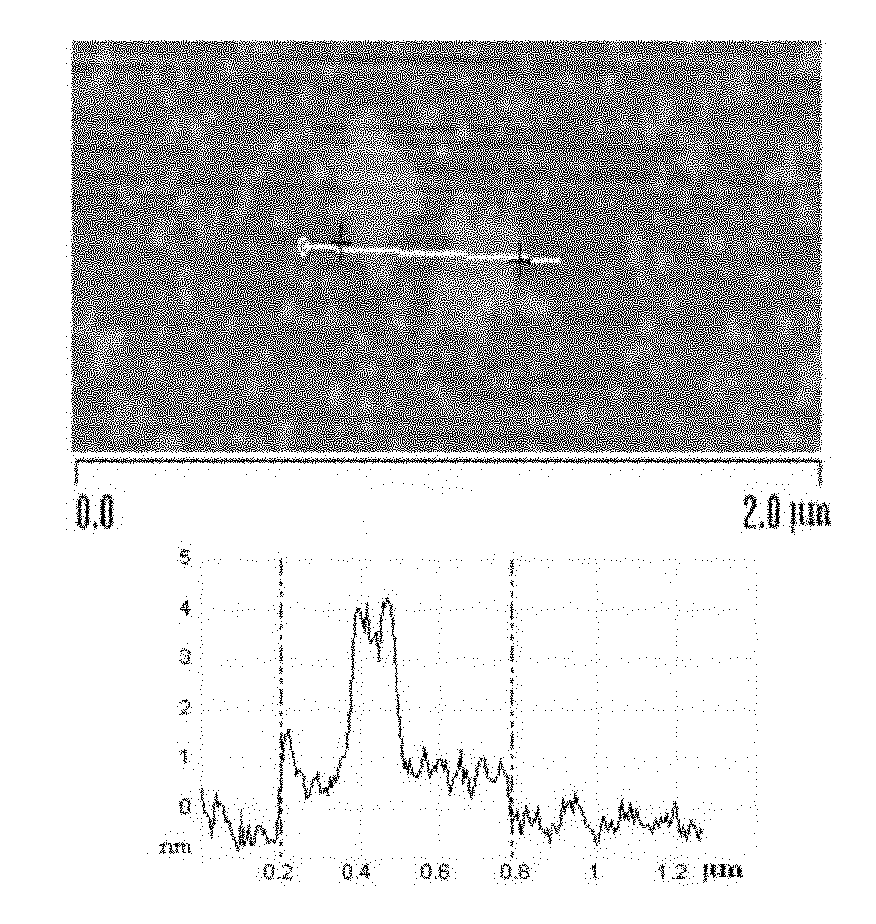

Image

Examples

preparation example Construction

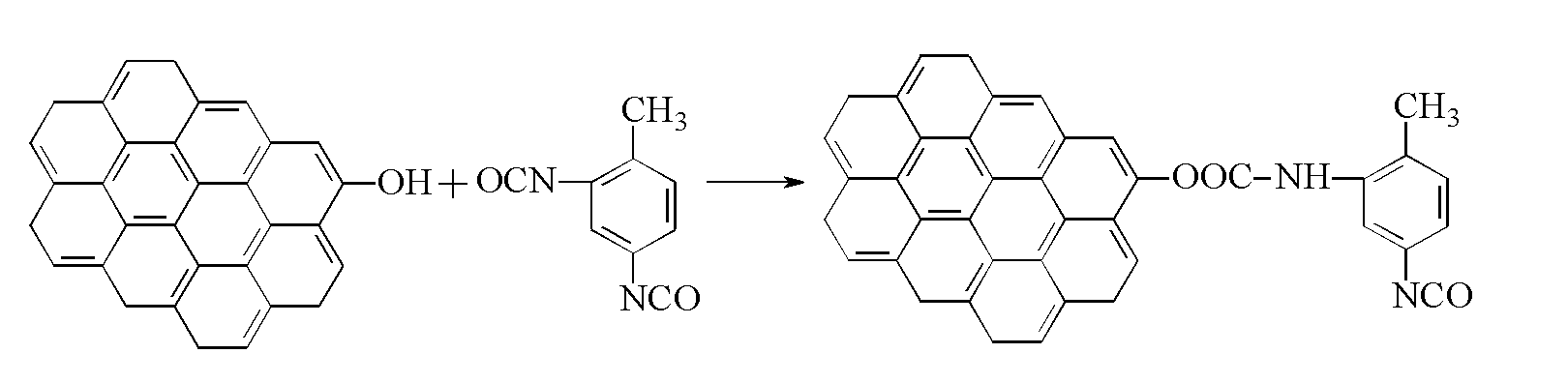

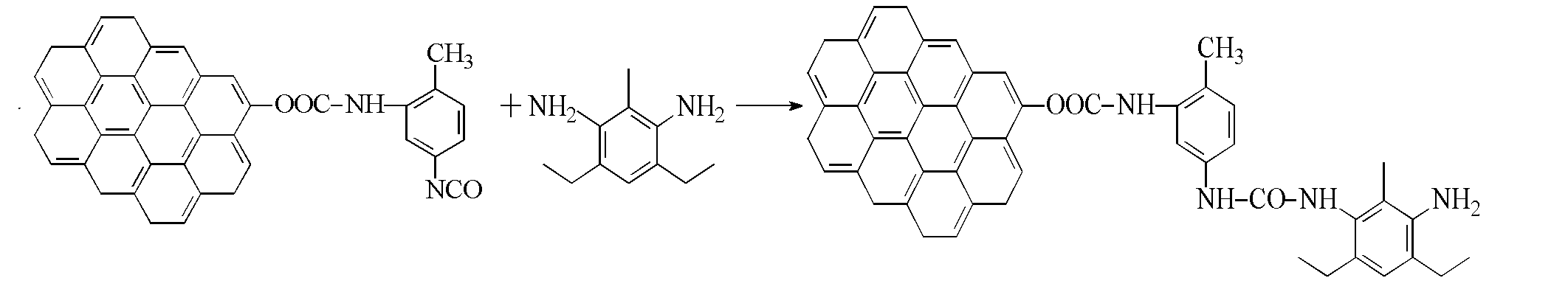

[0026] The present invention proposes a kind of preparation method of modified graphene / epoxy resin composite material, specifically comprises the following steps:

[0027] Step 1: Preparation of graphite oxide:

[0028] (1) Get graphite powder (particle size is micron order), KNO 3 The powder is mixed with concentrated sulfuric acid (concentration is 75wt% ~ 98.3wt%), and the mixing ratio is to add 1.5 ~ 2g KNO to every 1.5g graphite powder 3 , 65-69ml concentrated sulfuric acid, heat the obtained mixture to 35-40°C in a water bath, and then continue to add KMnO 4 Powder, the addition ratio is 8.0-9.5g of KMnO per 1.5g of graphite 4 , stir magnetically at 100-300r / min, and react for more than 6 hours; then slowly add deionized water to the mixture, and adjust the temperature of the water bath to 60°C-70°C, react for 25-40min, and then add deionized water to it Water, the amount of deionized water added is still added in the ratio of 100-200ml and 200-400ml of deionized wat...

Embodiment 1

[0043] Step 1: Preparation of graphite oxide

[0044] (1) Get graphite powder (micron grade), KNO 3 Powder, concentrated sulfuric acid (concentration is 98.3wt%) mix, add 1.5g KNO in the mixing ratio 1.5g graphite powder 3 , 69ml of concentrated sulfuric acid, when the resulting mixture was heated to 40°C in a water bath, 9g of KMnO was added 4 powder, magnetic stirring reaction for more than 6 hours; then slowly add 120ml of deionized water to the mixture, and adjust the temperature of the water bath to 60°C, after 30 minutes of reaction, add 300ml of deionized water to it, continue the reaction for 5 minutes, and add to the mixed liquid Dropping concentration is 30% H 2 o 2 , until the mixed liquid turns bright yellow;

[0045] (2). The mixed liquid was washed with deionized water until it was neutral, and dried under a vacuum condition of 0.1 MPa and 80° C. to obtain graphite oxide solid.

[0046] Step 2: Preparation of Graphene Oxide

[0047] Put 0.08g of graphite ox...

Embodiment 2

[0052] Change the amount of 2,4-toluene diisocyanate (TDI) added in step 3 in embodiment 1 to 0.0016mol, and other steps are exactly the same as in embodiment 1, and the prepared modified graphene / epoxy resin composite material Refer to the standard GBT1843-2008 casting body notch impact test, the impact strength is 3.75KJ / m 2 . The scanning electron microscope photos of the fracture of the impact sample are as follows: Figure 5 , its surface morphology is river-like, and the branches of the river are dense and will merge, so the dense, complex and irregular river morphology in the figure is finally formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com