Multi-stage wire feeding printing head for 3D printing of continuous fiber reinforced composite materials

A technology for reinforcing composite materials and continuous fibers, applied in the field of multi-stage wire feeding print heads, can solve the problems of low surface activity, low part strength, poor interface bonding performance of composite materials, etc., to enhance the interface bonding performance, improve the overall performance, The effect of good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

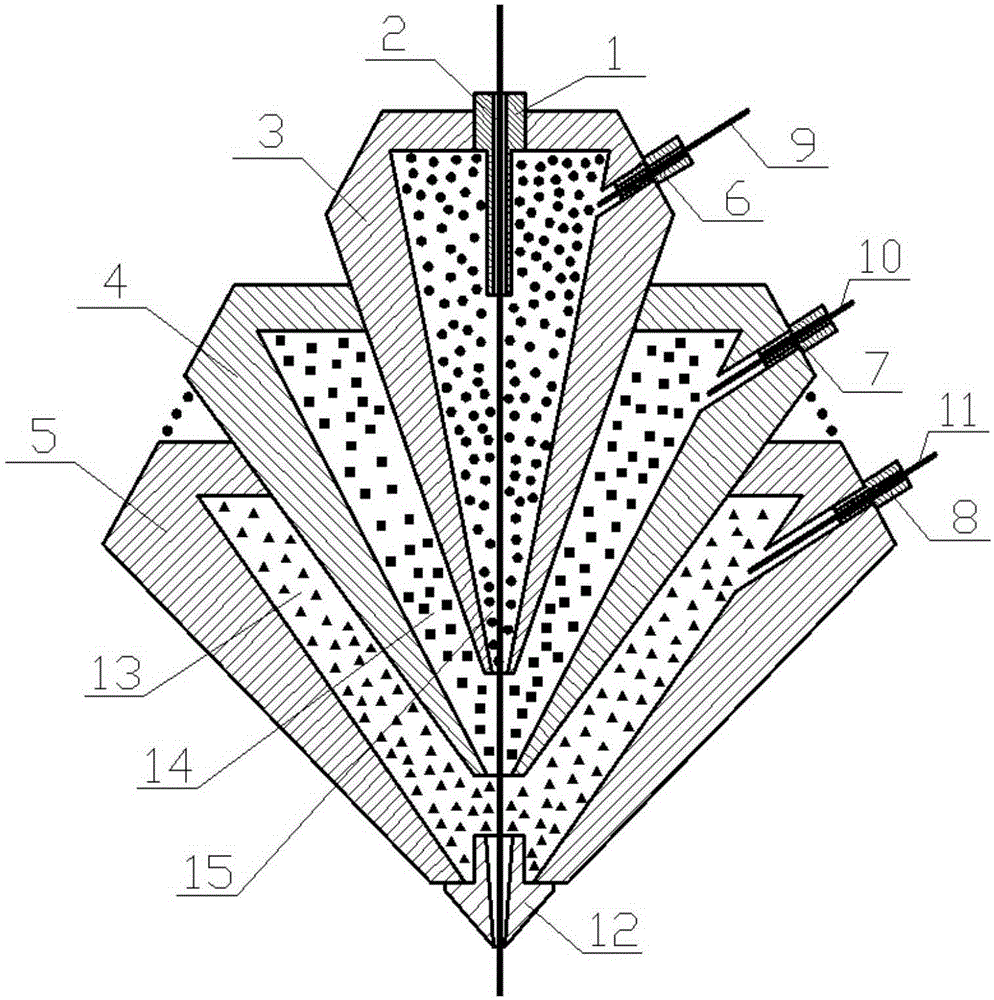

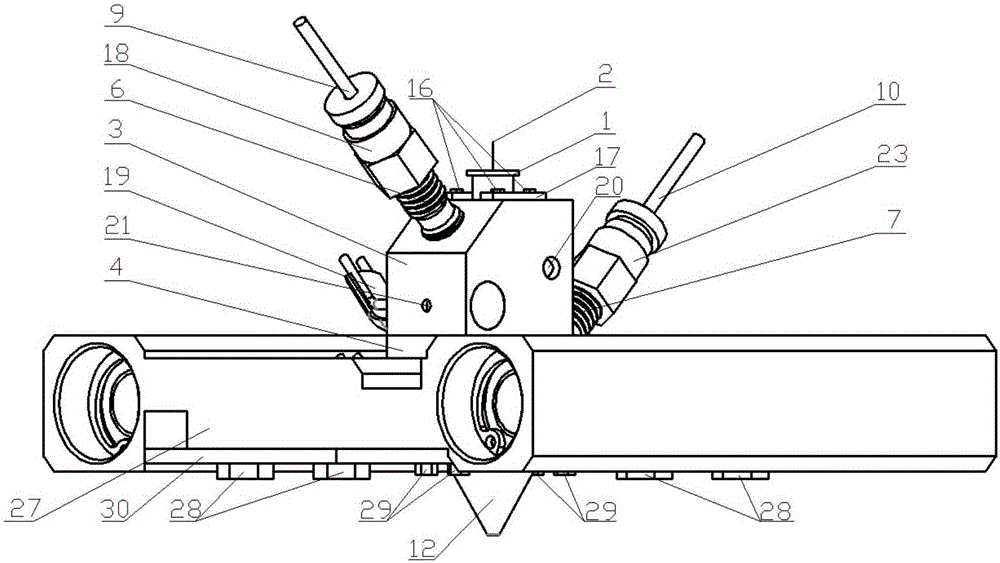

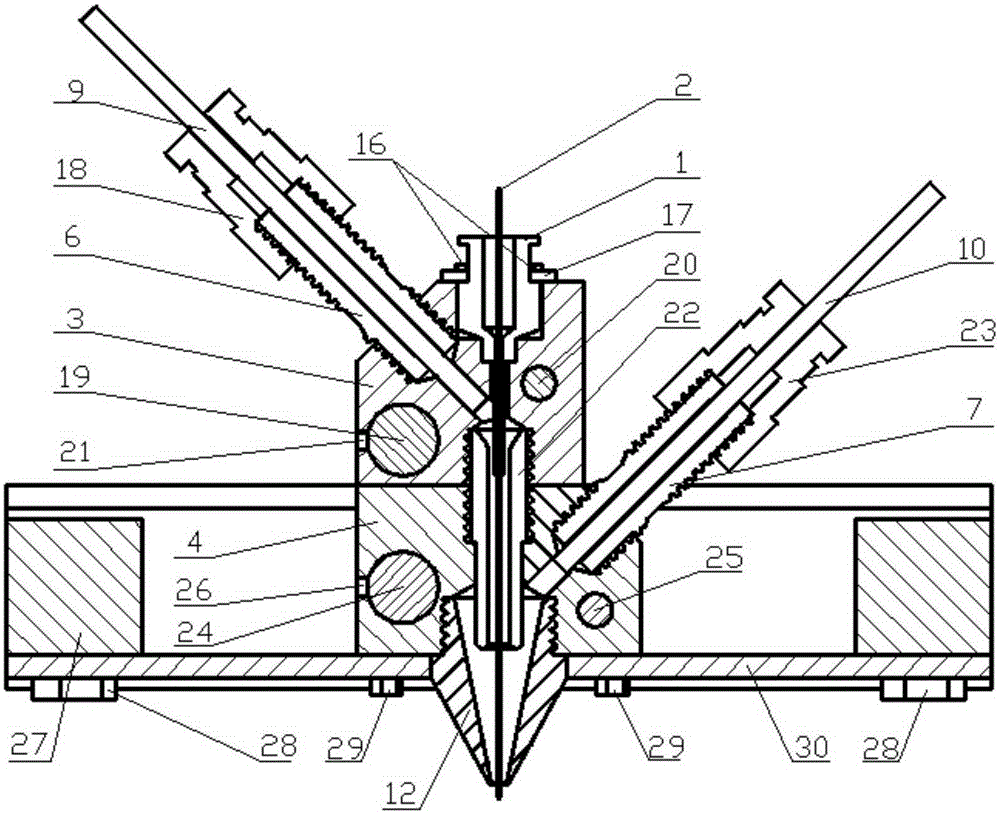

[0025] refer to figure 1 , a multi-stage wire-feed printing head for 3D printing of continuous fiber-reinforced composite materials, including a fiber conduit 1 fixed on the upper surface of a primary heating block 3, the inner hole of the fiber conduit 1 forms a fiber channel, and the primary throat 6 is fixed on a On one side of the stage heating block 3, the first-stage throat pipe 6 inner hole forms a first-stage inner hole, which has a lower melt index and a polymer material 9 with good wettability with fibers (such as flexible PLA, flexible ABS, etc.) from the first-level inner hole Pass through and enter the melting chamber of the primary heating block 3;

[0026] The primary heating block 3 is fixed on the top of the secondary heating block 4, the secondary throat 7 is fixed on one side of the secondary heating block 4, and the inner hole of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com