Preparation method for in-situ synthesis of three-dimensional graphene-reinforced copper-based composite material

A copper-based composite material and in-situ synthesis technology, which is applied in the field of in-situ synthesis of three-dimensional graphene-reinforced copper-based composite materials and nanomaterial preparation, and can solve the problem of decreased strengthening effect, loss of graphene mechanical properties, and conductive structural stability. , poor mechanical properties and poor electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In-situ synthesis of three-dimensional graphene-reinforced copper-based composite material preparation method, characterized in that it includes the following process:

[0024] ① Powdered copper nitrate trihydrate (Cu(NO) 3 ·3H 2 O) is the copper source, and the molar ratio of C and Cu is 3:1 to 4:1 and the solid carbon source glucose (C 6 h 12 o 6 ) or citric acid (C 6 h 8 o 7 ), mixed with water-soluble salt template sodium chloride (NaCl) according to the elemental molar ratio of Na to Cu of 100:1 to 200:1, and then added to deionized water according to the mass ratio of NaCl to water of 1:3 to 1:5 Dissolve and stir evenly with magnetic force to obtain a uniform and transparent precursor solution.

[0025] ②Put the mixed solution in step ① into the refrigerator for 12-24 hours at -20°C to obtain a solid mixed sample, then place it in a freeze dryer at -50-10°C for 24-36 hours and dehydrate Obtain dry solid powder, grind and sieve to obtain mixed powder precur...

Embodiment 1

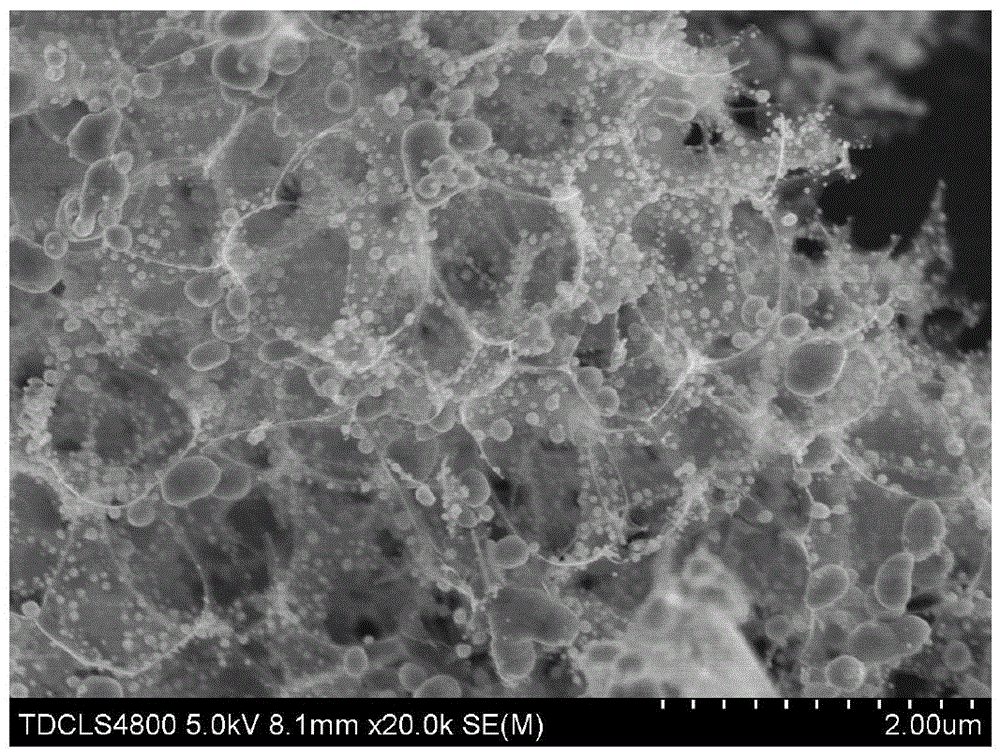

[0032]Weigh 36.590g of sodium chloride, 0.938g of glucose, and 2.265g of copper nitrate trihydrate into a beaker, weigh 121mL of deionized water to dissolve, stir evenly (>6h) to obtain a clear solution, put it in a petri dish and freeze in the refrigerator Freeze at -20°C for 24 hours in the room; freeze-dry the frozen samples in a freeze dryer, the freeze-drying conditions are: -20°C, and the freeze-drying time is 24 hours. The freeze-dried sample was ground to obtain precursor composite powder (powder particle size ~ 100 mesh); the precursor powder was placed in a tube furnace under a hydrogen atmosphere (heating rate 10°C / min, holding temperature 750°C, holding time 2h , gas flow rate 100mL / min) calcining, after the heat preservation is completed, it is rapidly cooled to room temperature (down to 100°C within 5min), and the obtained composite powder is washed with suction filtration and water to remove the sodium chloride template, and placed in a vacuum drying oven at 80°C...

Embodiment 2

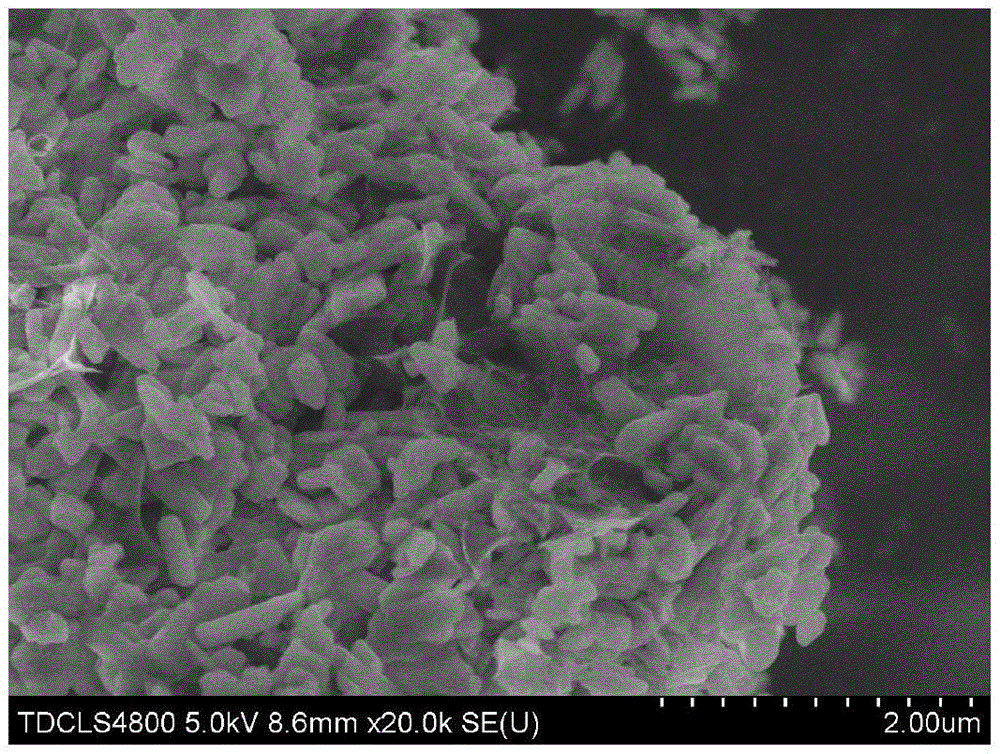

[0034] Weigh 36.590g of sodium chloride, 0.938g of glucose, and 2.265g of copper nitrate trihydrate into a beaker, weigh 121mL of deionized water to dissolve, stir evenly (>6h) to obtain a clear solution, put it in a petri dish and freeze in the refrigerator Freeze at -20°C for 24 hours in the room; freeze-dry the frozen samples in a freeze dryer, the freeze-drying conditions are: -20°C, and the freeze-drying time is 24 hours. The freeze-dried sample was ground to obtain precursor composite powder (powder particle size ~ 100 mesh); the precursor powder was placed in a tube furnace under a hydrogen atmosphere (heating rate 10°C / min, holding temperature 750°C, holding time 2h , gas flow rate 100mL / min) calcining, after the heat preservation is completed, it is rapidly cooled to room temperature (down to 100°C within 5min), and the obtained composite powder is washed with suction filtration and water to remove the sodium chloride template, and placed in a vacuum drying oven at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com