Reversible air battery using piperidine as hydrogen storage media

An air battery and piperidine technology, applied in the direction of fuel cell half-cells and secondary battery-type half-cells, to achieve the effect of increasing specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

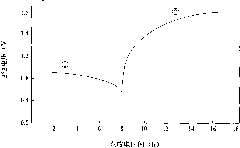

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of polypyrrole-modified carbon-supported noble metal catalyst

[0041] Disperse 1 to 10 grams of carbon material into water to form a suspension with a mass ratio of 1:15; add glacial acetic acid to adjust the pH value to 2.5, and stir at room temperature for 10 minutes; add the carbon material to pyrrole at a mass ratio of 1:0.05 Stir pyrrole for 5 minutes, then add 1 to 5 grams of the above precious metal chloride; stir at room temperature for 3 hours, then add 0.05 grams of H 2 o 2 ; After stirring at room temperature for 3 hours, heat to 70°C; slowly add 300ml to a concentration of 0.1M L -1 After the reductant alkaline sodium borohydride solution, stirred vigorously for 30min, and cooled naturally; after washing and filtering with deionized water, vacuum drying at 70°C for 6h, and heat treatment at 300°C for 5h under an Ar inert atmosphere to obtain polypyrrole-modified carbon Carry noble metal catalyst, its loading capacity of noble metal ...

Embodiment 2

[0044] Example 2: Preparation of polypyrrole-modified carbon-supported noble metal alloy catalyst

[0045] Disperse 100-2000 grams of carbon material into water to make a suspension, the mass ratio of which is 1:15; add hydrochloric acid to adjust the pH value to 3, stir at room temperature for 30 minutes; add pyrrole according to the mass ratio of carbon black to pyrrole as 1:0.3 Stir for 10min, then add the corresponding elements and the corresponding amount of chloride according to Table 2; stir at room temperature for 10h, then add 100 grams of H 2 o 2 ; After stirring at room temperature for 10 hours, heat to 90°C; slowly add 3000ml to a concentration of 0.3M L -1 The reductant alkaline sodium borohydride solution, stirred vigorously for 60min, and cooled naturally; after washing and filtering with deionized water, vacuum drying at 90°C for 12h, and then drying in N 2 The polypyrrole-modified carbon-supported noble metal alloy catalyst was prepared by heat treatment at ...

Embodiment 3

[0049] Example 3: Preparation of positive and negative electrodes

[0050] The obtained polypyrrole-modified carbon-supported noble metal or noble metal alloy catalyst, water, 5wt.% perfluorosulfonic acid resin (Nafion) solution and absolute ethanol are mixed and prepared according to the mass ratio of 1:3:2~7:3~6 Slurry is coated on carbon paper or carbon cloth treated with hydrophilicity, and the negative electrode is made after natural drying; the slurry is coated on carbon paper or carbon cloth with water-repellent treatment, and the negative electrode is made after natural drying Positive. The loading amount of the catalyst is 1~67mg cm -2 .

[0051] Table 3 Preparation formula of positive and negative electrodes and loading amount of catalyst in electrode

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com