Reservoir underwater walking sand suction and discharge device

A walking type and reservoir technology, which is applied in water conservancy projects, sea area projects, earth movers/excavators, etc., can solve problems such as small operation range, endangering residents' lives and property, and erosion, so as to expand the space operation area, High efficiency of sand suction and dredging, and the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

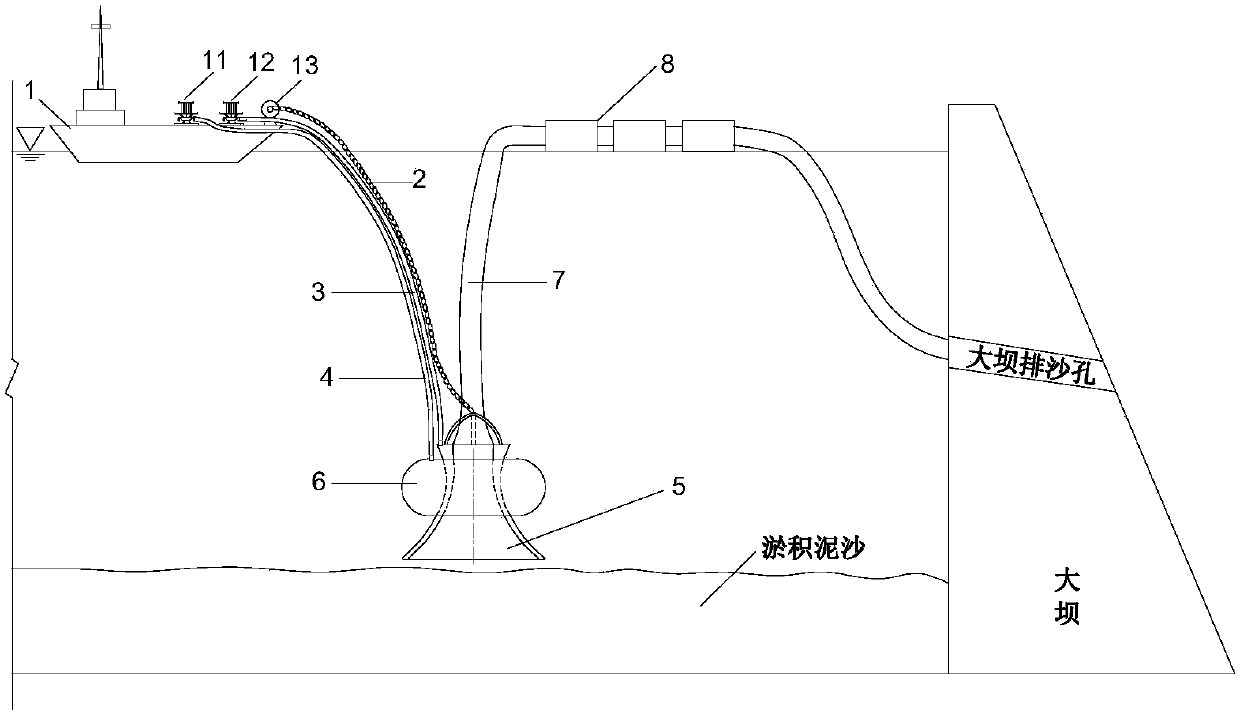

[0023] Please refer to figure 1 , The underwater walking sand suction and discharge device for the reservoir of the present invention includes a working boat 1, a traction steel rope 2, a water filling pipe 3, an air filling pipe 4, a porous sand suction table 5, an annular air cavity 6, a sand conveying pipe 7, and a buoy 8.

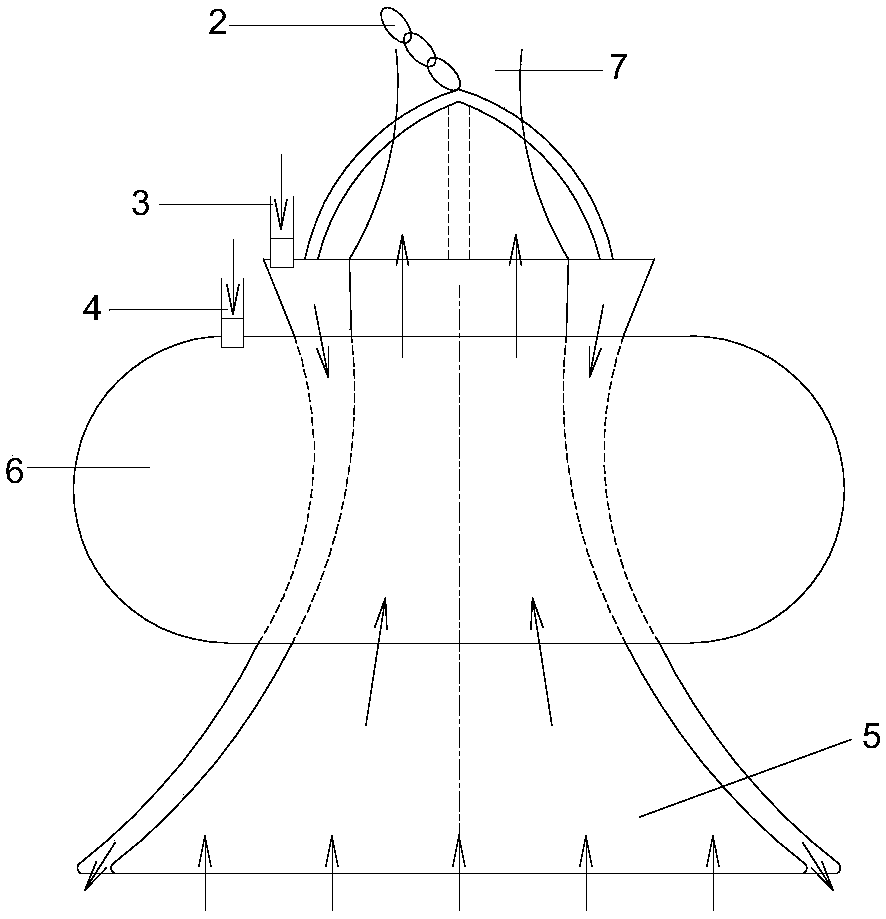

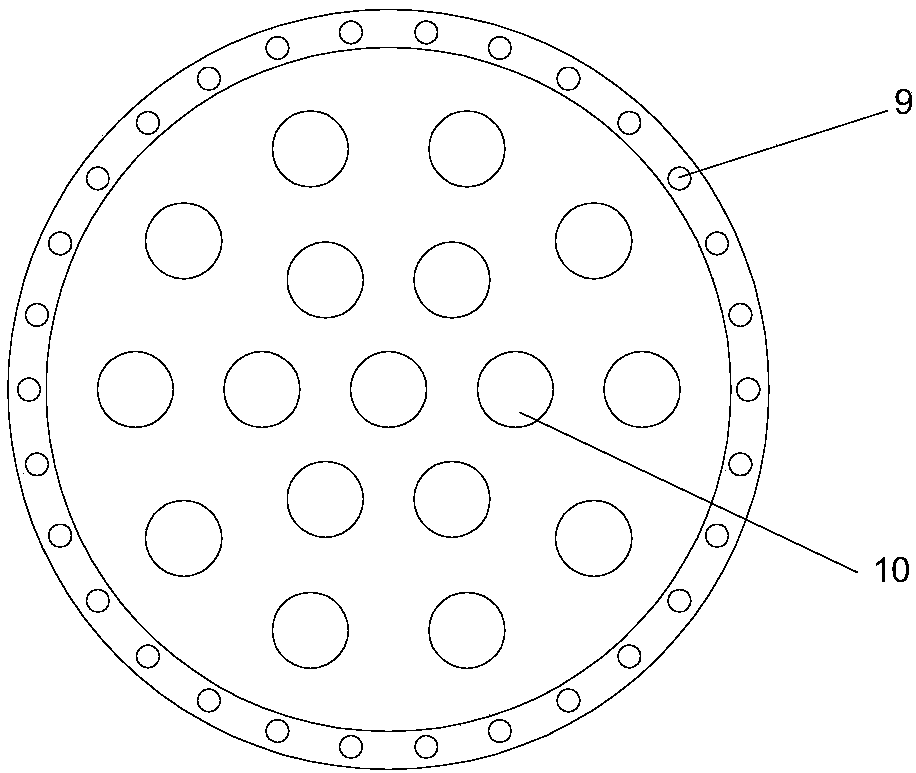

[0024] The working boat 1 is placed on the water surface of the reservoir, and the working boat 1 is provided with a water pump 11, an air pump 12, a winch 13 and a positioning system. The porous sand suction tray 5 is arranged on the sedimentation bed surface at the bottom of the reservoir, such as figure 2 and image 3 As shown, the porous sand-absorbing tray 5 is approximately in the shape of an inverted funnel, the disc surface diameter of the chassis is not less than 100c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com