Lead storage battery

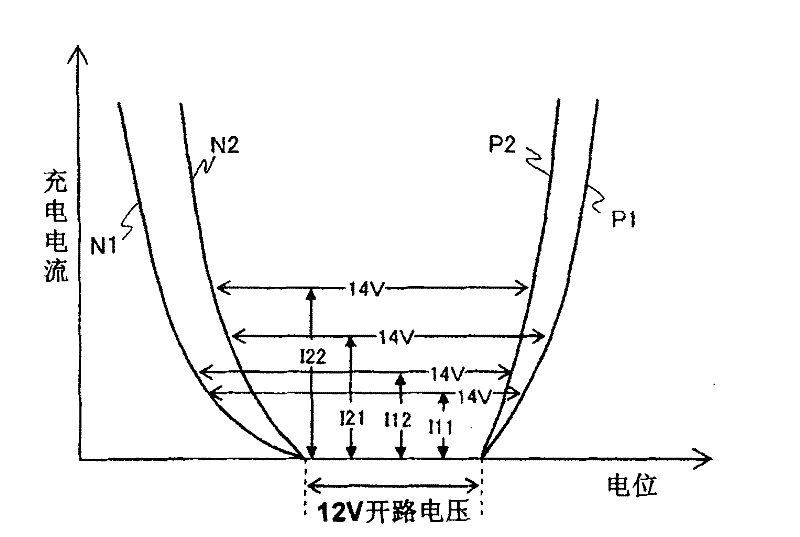

A lead-acid battery, charging and discharging technology, applied in lead-acid batteries, lead-acid battery electrodes, battery electrodes, etc., can solve problems such as inability to obtain effects, and achieve improved charging acceptance performance and service life performance, improved charging acceptance performance, and improved service life. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0114] Add water to the mixture of lead oxide, red lead (trilead tetroxide) and short fiber (polyethylene terephthalate short fiber, the same below) and knead, then add a small amount of dilute sulfuric acid several times While kneading, the positive electrode active material paste was produced. The active material paste was filled in an expanded current collector produced by stretching a rolled sheet made of lead alloy, aged at 40°C and a humidity of 95% for 24 hours, and then dried to produce an unformed positive electrode plate. .

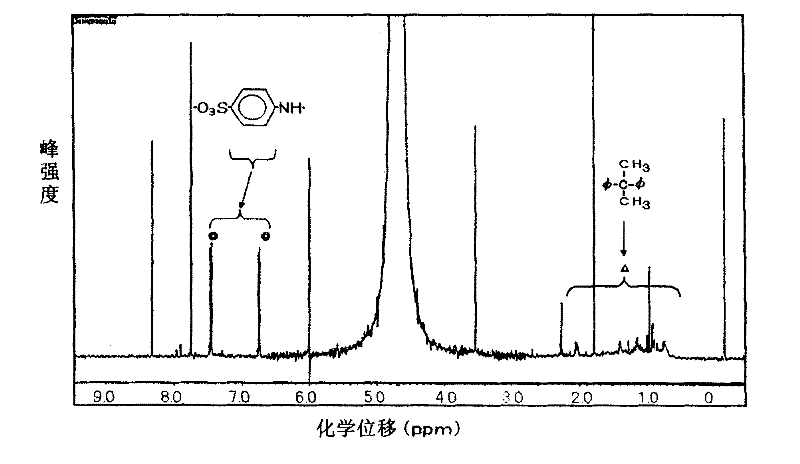

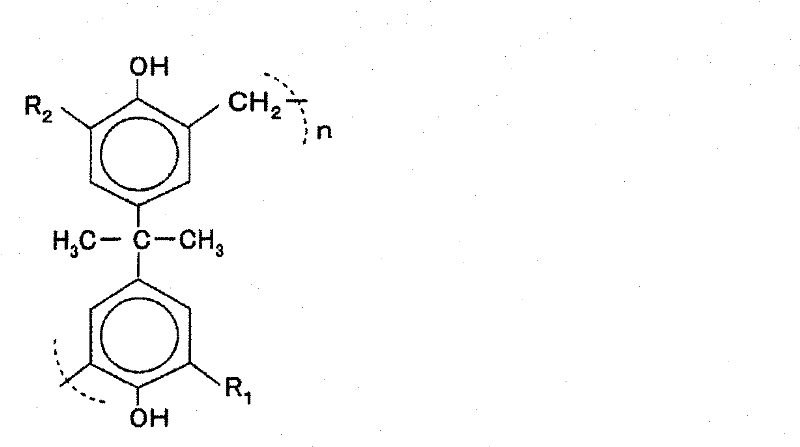

[0115] Next, an unformed negative electrode plate was fabricated. Water is added to a mixture of lead oxide, short fibers, barium sulfate, carbonaceous conductive material, and an organic compound that has an effect of suppressing the coarsening of the negative electrode active material, and kneading is performed, and then, dilute sulfuric acid is added in small amounts and kneaded. Refining to make active material paste for negative electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com