Copper-based sliding material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

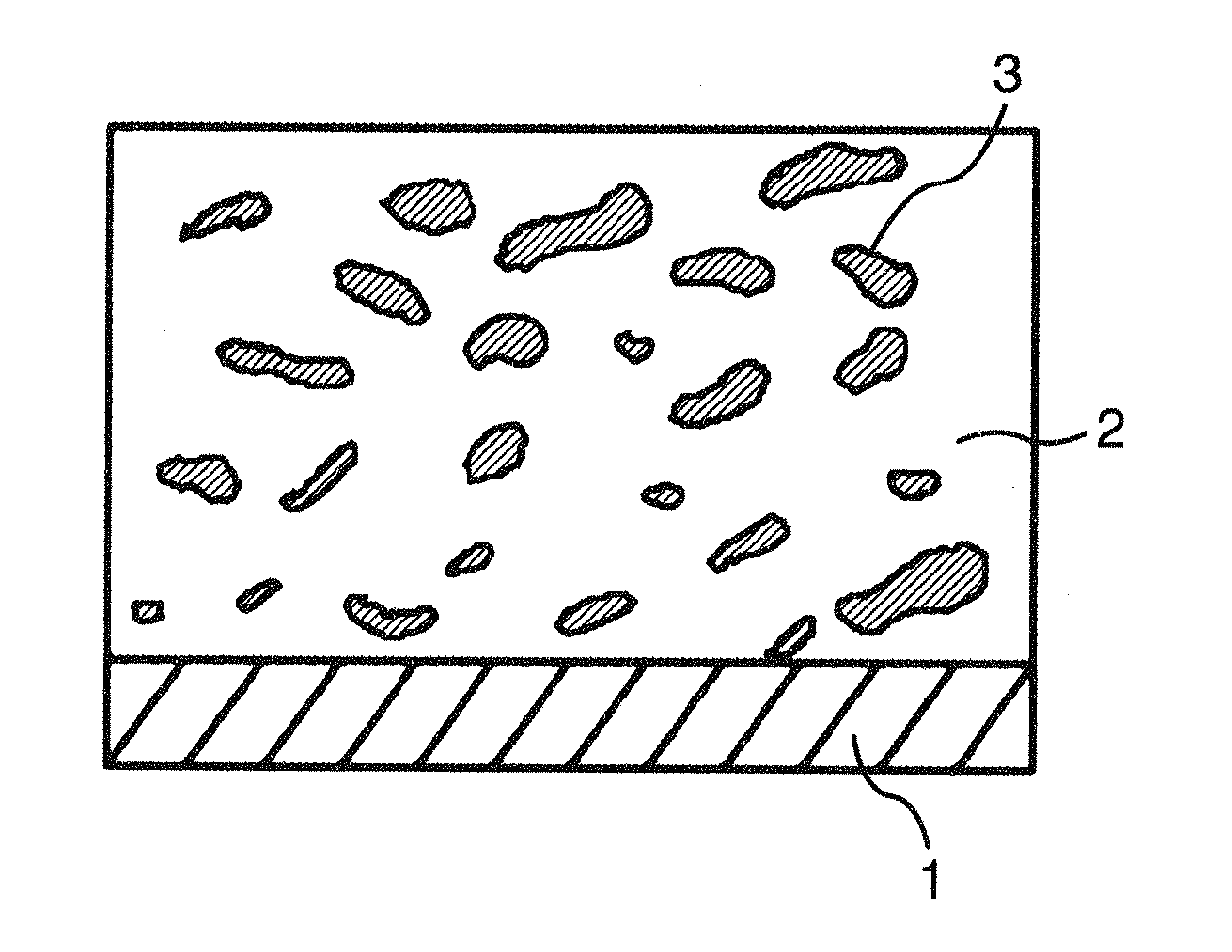

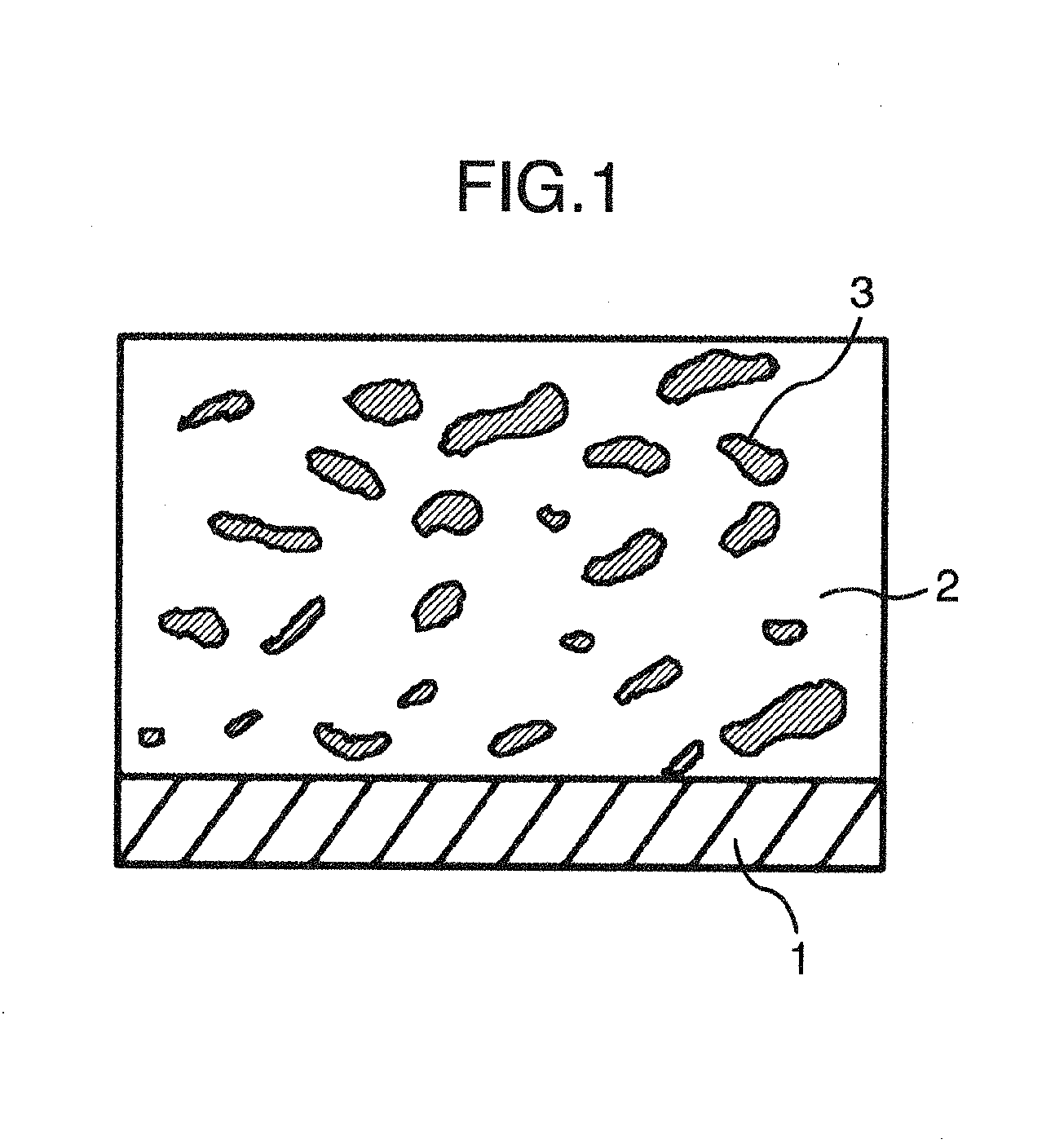

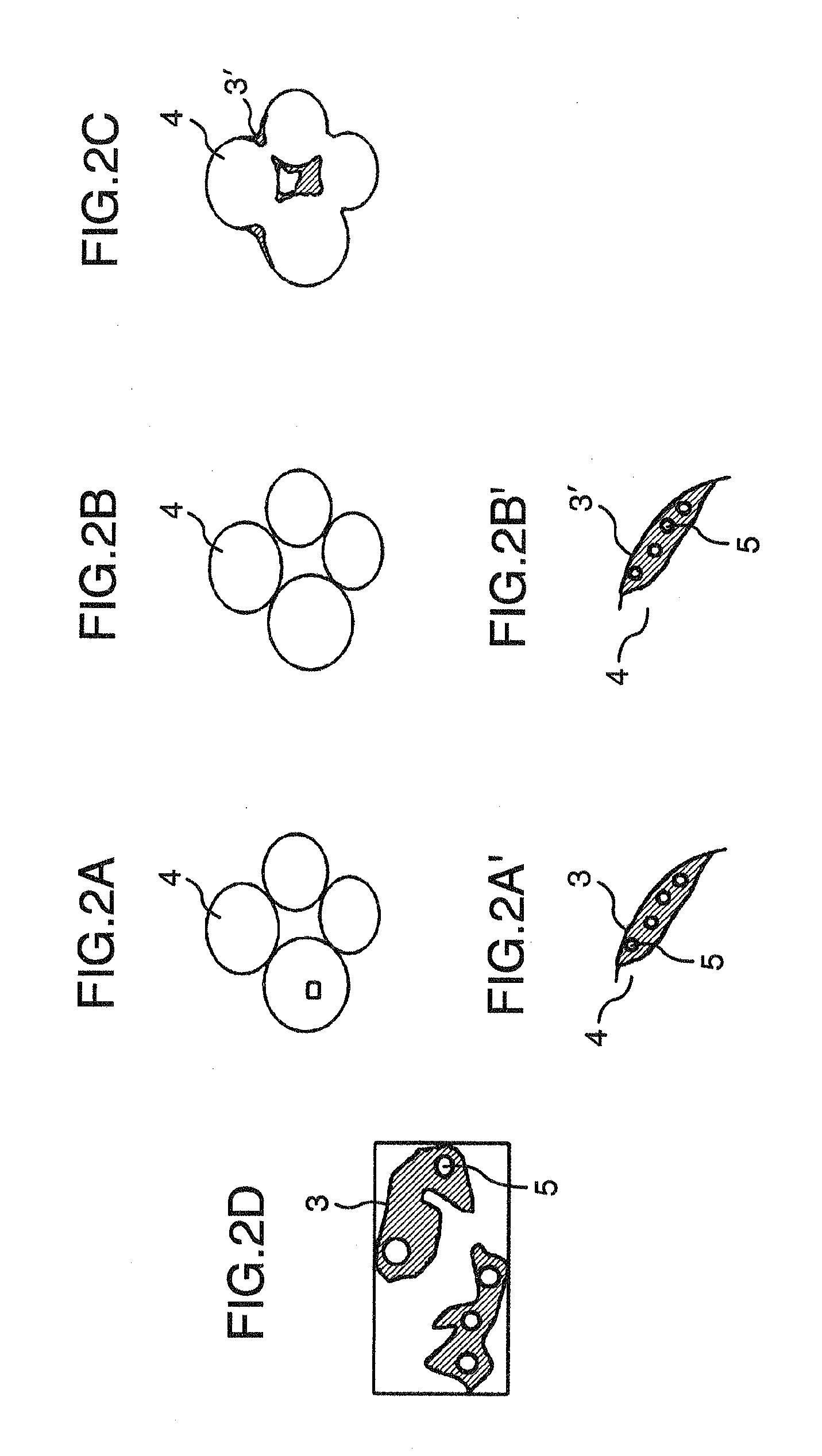

Image

Examples

examples

[0047]Examples 1 to 18 of a Bi-containing Cu alloy according to an embodiment of the invention, and Comparative Examples 21 to 30 were measured with the average particle size of a Bi phase and subjected to a bearing fatigue test. Table 1 shows compositions of Examples 1 to 18 and Comparative Examples 21 to 30. As for Examples 1 to 18, a Cu alloy powder was produced by an atomizing process and mixed with an inorganic compound with use of a general mixer. In this way, the inorganic compound was embedded in the Bi phase on a surface of the Cu alloy powder particle so as to satisfy the component ratio in Table 1. Subsequently, the powder mixture was scattered onto a steel strip and subjected to repeated sintering and rolling processes to produce a sliding material. The sintering was performed at a temperature of 850° C. The sliding material was formed into a semi-cylindrical shape to produce a sliding bearing.

TABLE 1ContentInorganic compoundInorganiccompoundspecificBi phase ingravity / Bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com