Preparation method of cathode of low-medium temperature solid oxide fuel cell

A fuel cell cathode, solid oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cathode polarization impedance, poor repeatability, slow transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

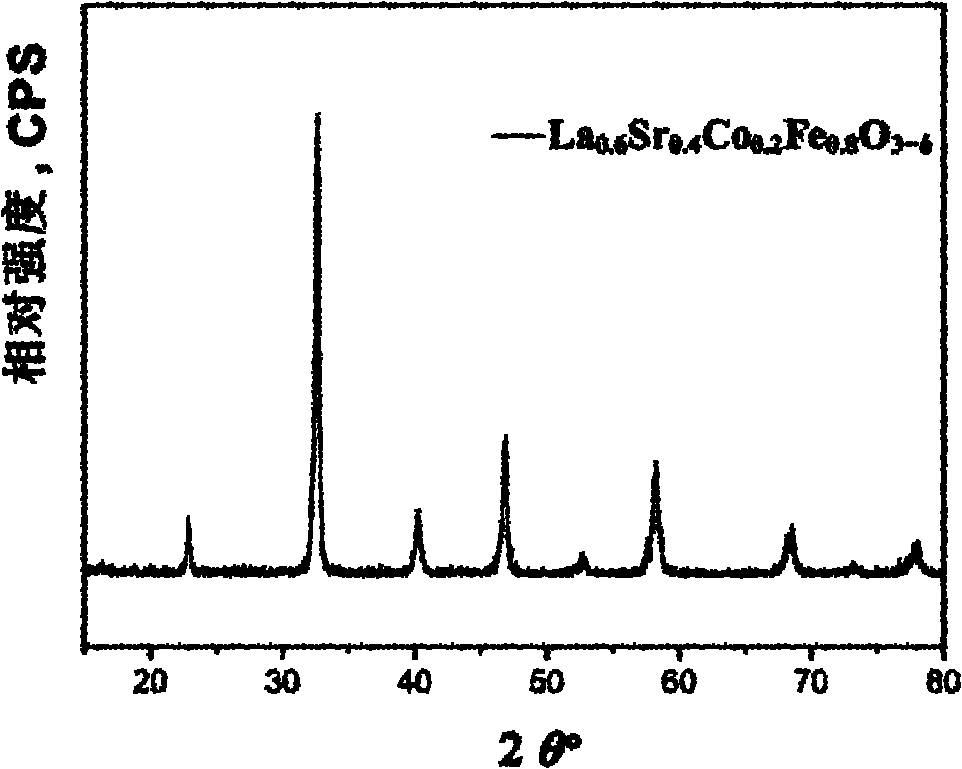

[0028] (1) Synthesis of La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ Nanopowder: take La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 )2 , Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water, and then EDTA and citric acid were added according to the ratio of the total number of metal ions: EDTA: citric acid (number of moles) = 1:1:1.2, and then NH 3 ·H 2 O to adjust the pH value of the solution to 6-10. Evaporate and concentrate at 80-90 to obtain a reddish-brown gel. The gel is heated in an air atmosphere at 200-400° C. for 5-8 hours to obtain a precursor. The precursor is calcined in air at 700-1000°C for 2-10 hours to obtain La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ .

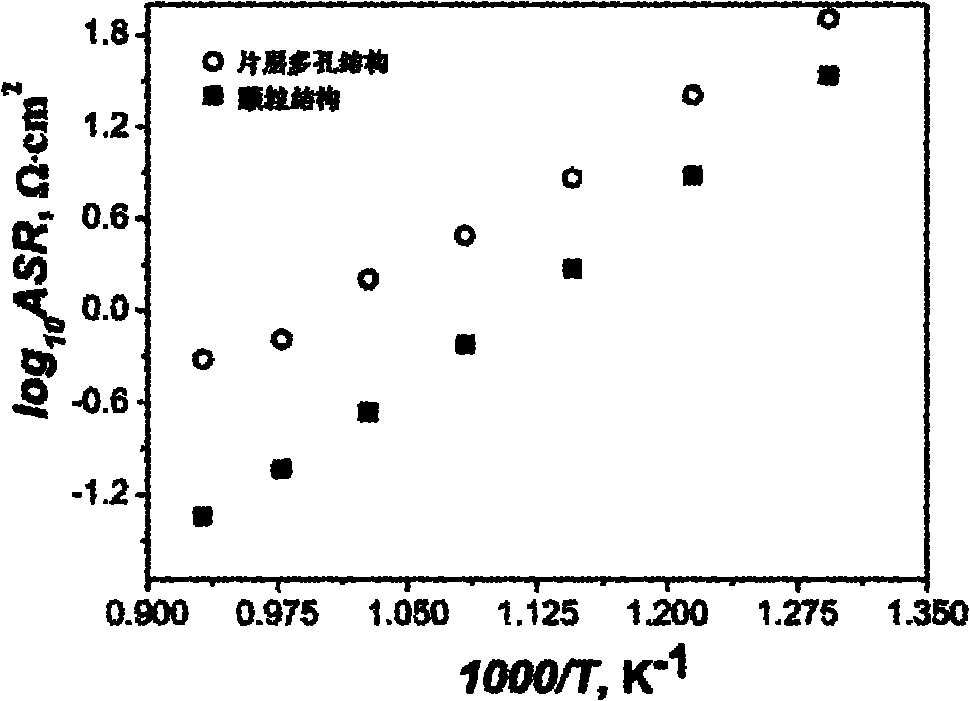

[0029] (2)La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ Preparation of the cathode layer: the mass ratio of 1 to 5% La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ The powder is mixed with PVB with a mass ratio of 1-5%, 1-5% PVP, 1-10ml terpineol, 1% graphite powder and ethanol, and ball milled for 2-10 hours to form a ...

Embodiment 2

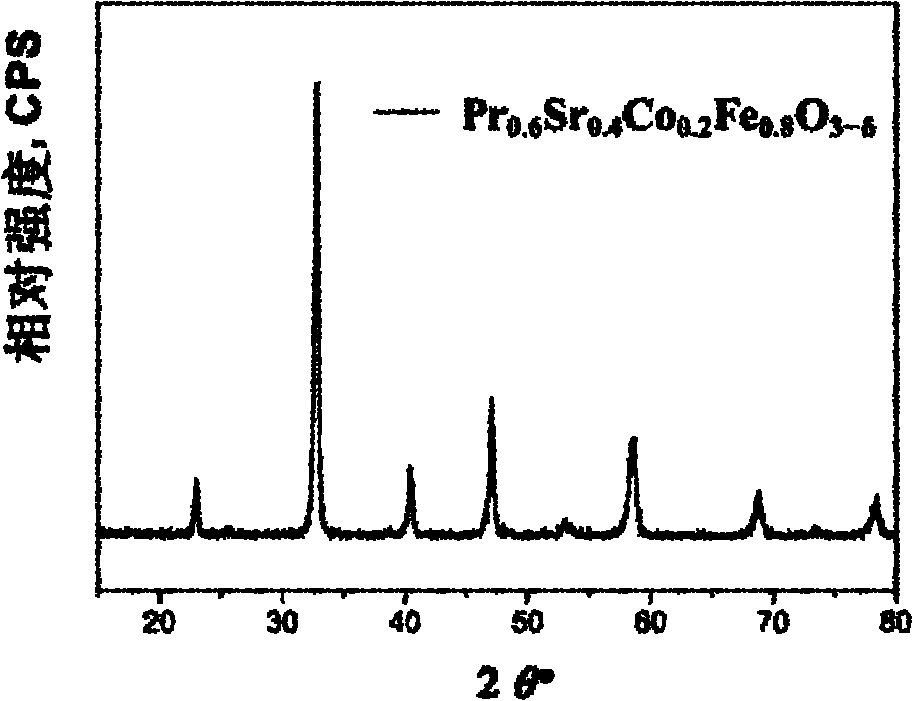

[0037] (1) Synthesis of Pr 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ Nanopowder: Pr(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water, and then EDTA and citric acid were added according to the ratio of the total number of metal ions: EDTA: citric acid (number of moles) = 1:1:1.2, and then NH 3 ·H 2 O to adjust the pH value of the solution to 6-10. Evaporate and concentrate at 80-90° C. to obtain a reddish-brown gel. The gel is heated in an air atmosphere at 200-400° C. for 5-8 hours to obtain a precursor. The precursor is calcined in air at 700-1000°C for 2-10 hours to obtain Pr 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ .

[0038] (2) Preparation of the cathode layer: the obtained Pr 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ The powder is mixed with 1-5% PVB, 1-5% PVP, 1-10ml terpineol and ethanol, and ball milled for 2-10 hours to form a slurry mixture; heat the GDC electrolyte ceramic sheet on an electric heating plate to 100...

Embodiment 3

[0041] (1) Synthesis of Ga 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ Nanopowder: take Ga(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water, and then EDTA and citric acid were added according to the ratio of the total number of metal ions: EDTA: citric acid (number of moles) = 1:1:1.2, and then NH 3 ·H 2 O to adjust the pH value of the solution to 6-10. Evaporate and concentrate at 80-90° C. to obtain a reddish-brown gel. The gel is heated in an air atmosphere at 200-400° C. for 5-8 hours to obtain a precursor. The precursor is calcined in air at 700-1000°C for 2-10 hours to obtain Ga 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ .

[0042] (2) Ga 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ Cathode layer preparation: Ga 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ The powder is mixed with PVB with a mass ratio of 1-5%, 1-5% PVP, 1-10ml terpineol, 1% graphite powder and ethanol, and ball milled for 2-10 hours to form a slurry mixture; Gadolinium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com