Lead storage battery

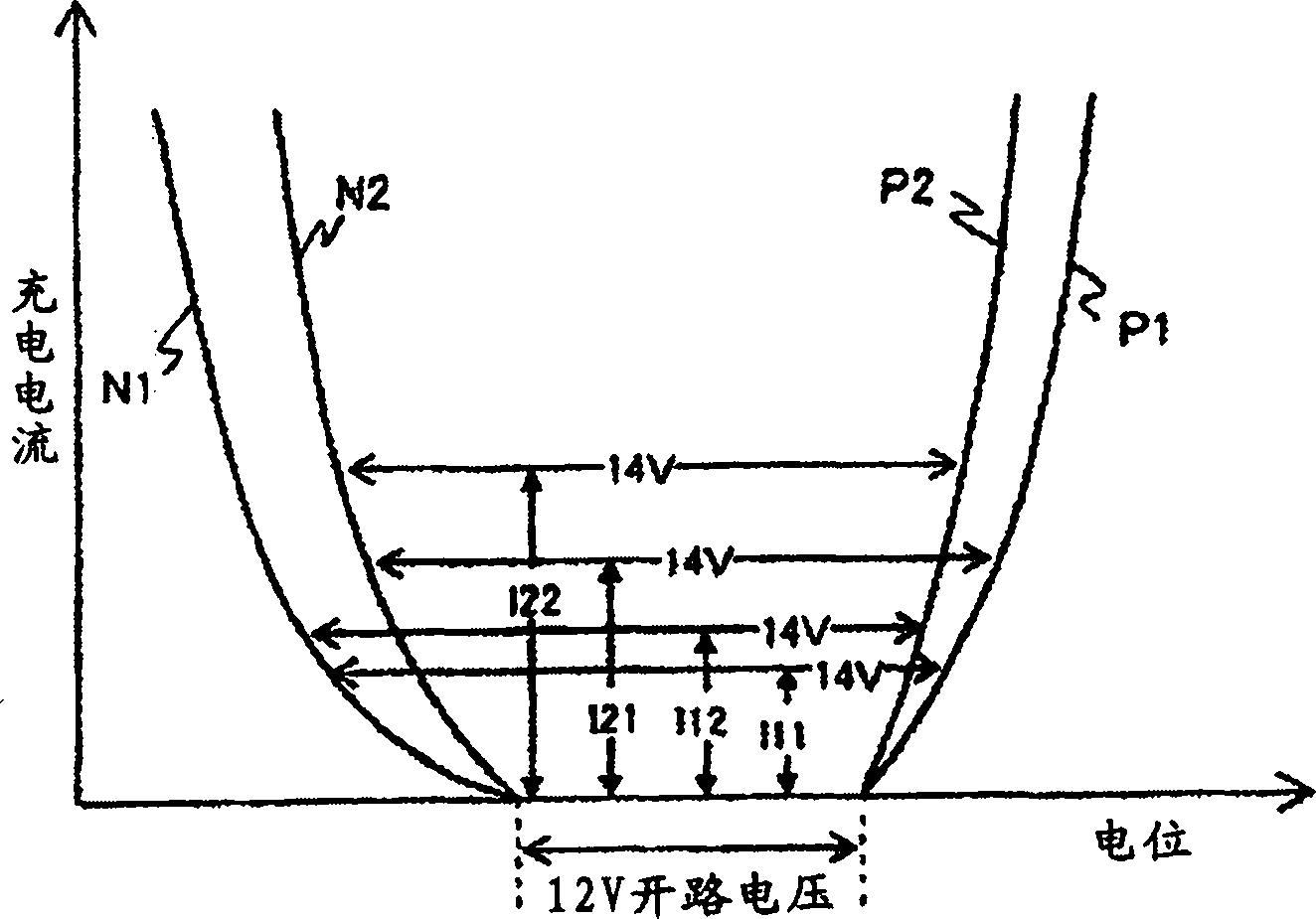

一种铅酸蓄电池、电解液的技术,应用在铅酸蓄电池、铅酸蓄电池电极、铅酸蓄电池建设等方向,能够解决没得到多大效果、正极活性物质易于发生泥状化等问题,达到抑制粗大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] In Japan, lead-acid batteries for automobiles are generally liquid-type, and there is no JIS standard (JIS D5301) for lead-acid batteries for engine starting with regard to valve-regulated lead-acid batteries. Therefore, in this embodiment, as an example, a 12V valve-regulated lead-acid battery was produced using a liquid-type battery case of B20 size specified by the JIS standard, but the present invention is not limited to the standard (structure) of the battery. . That is, no matter what kind of standard (structure) valve-regulated lead-acid battery is, by changing the existing positive and negative active materials and electrolyte specific gravity ranges to the present invention, the desired purpose of the present invention can be achieved.

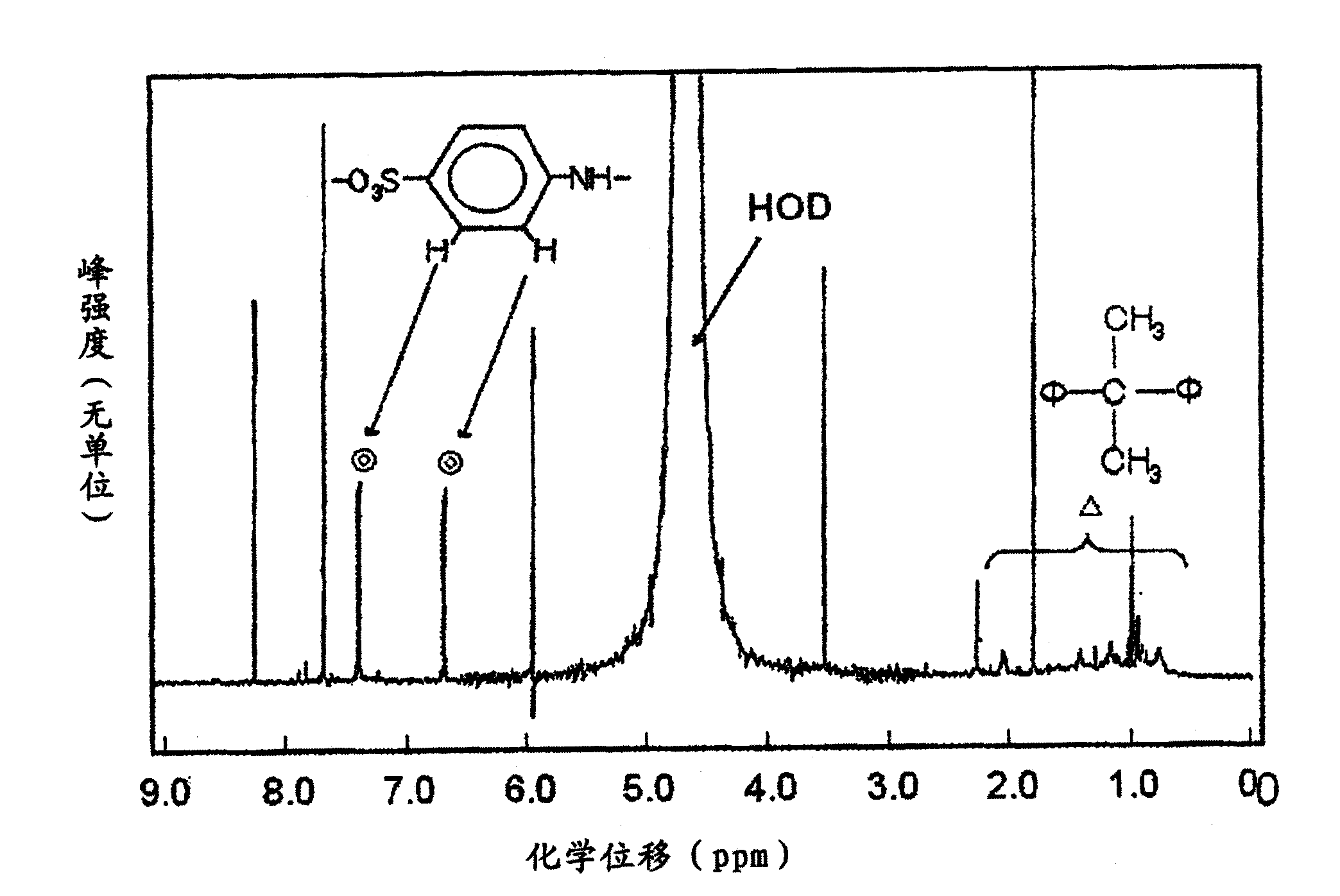

[0106] Initially, an unformed positive plate is produced. Water is added to the mixture of lead oxide, trilead tetroxide and chopped fibers (polyethylene terephthalate short fibers, the same below) for kneading, and then a sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

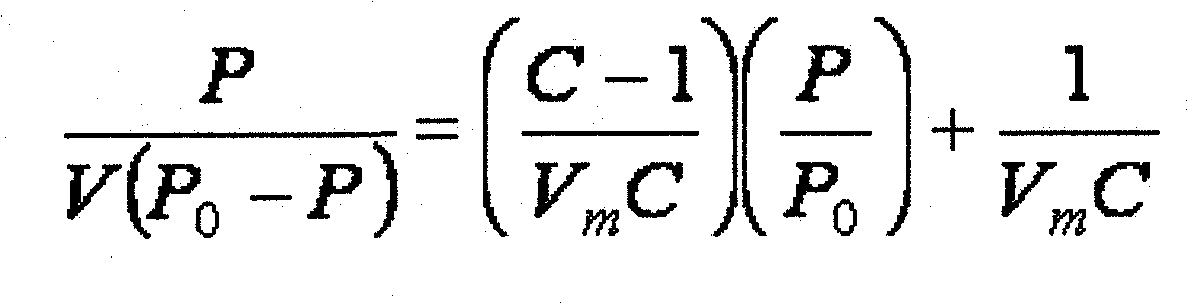

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com