Modified ethylene-based films to promote isocyanate chemical reactions in polyurethane laminating adhesives

一种多层薄膜、乙烯基聚合物的技术,应用在促进异氰酸酯在聚氨酯层压粘合剂中化学反应的改性的乙烯基薄膜领域,能够解决不能增加粘度、不会具有粘合强度、层压体有缺陷等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

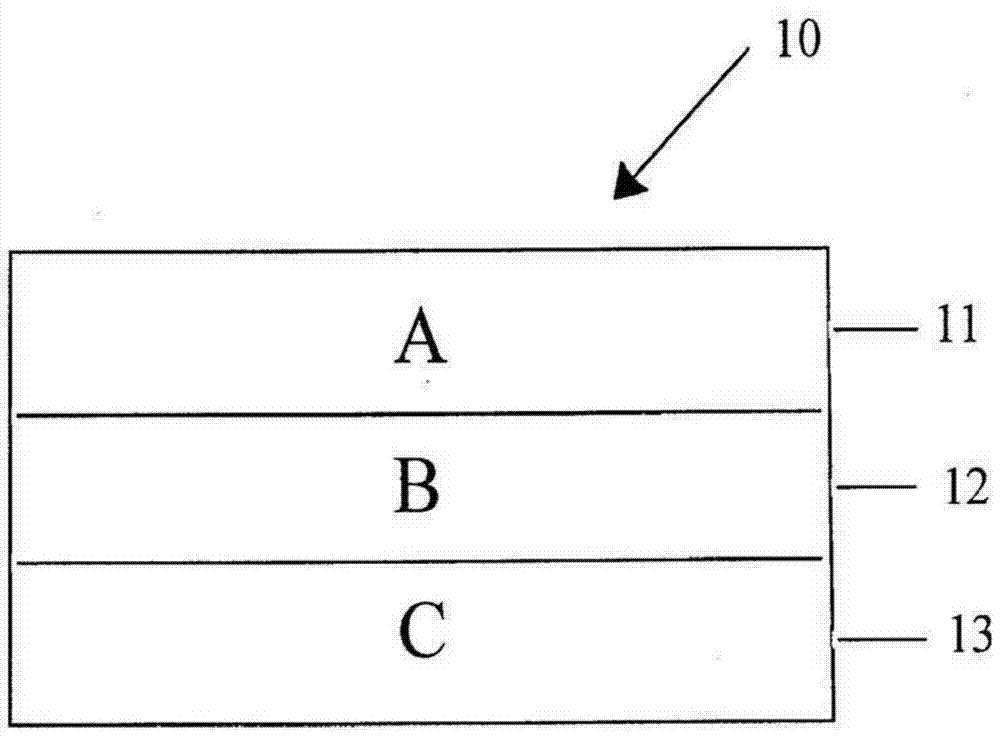

[0017] As discussed above, the present invention provides a multilayer film comprising at least two layers A and B:

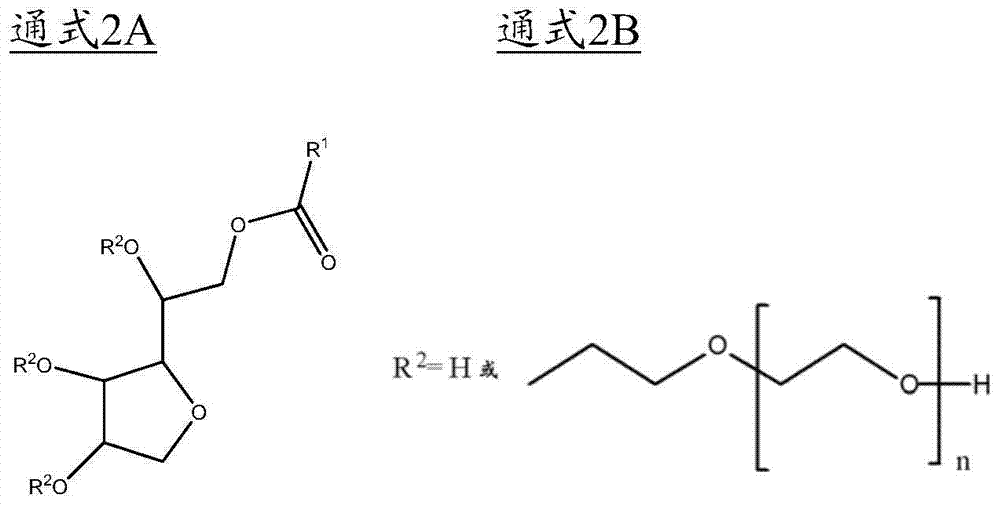

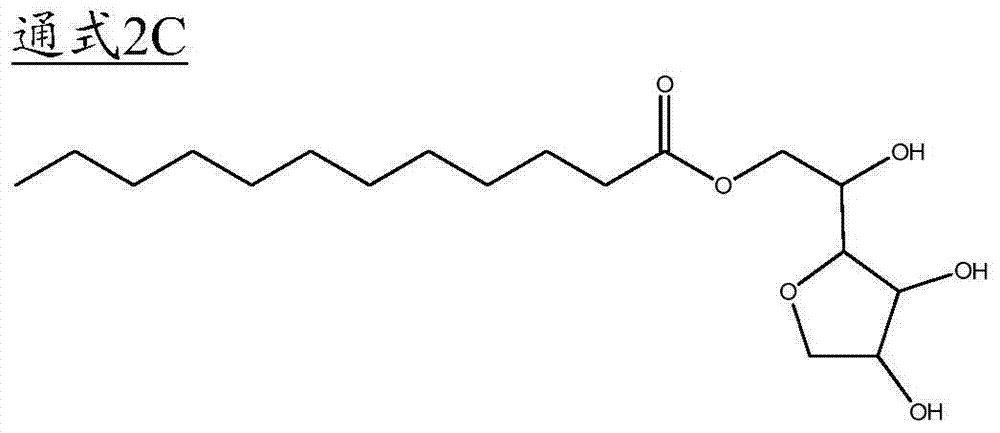

[0018] A. Film layer A formed from composition A comprising at least the following components: vinyl polymer and one of the following components (1 or 2):

[0019] 1) at least one polyol, alkoxylated amine, alkoxylated amide, amine-containing compound, and / or hydroxyl-containing compound; and a curing catalyst; or

[0020] 2) a curing catalyst comprising at least one hydroxyl group and at least one organometallic salt, or at least one hydroxyl group and a tertiary amine; and

[0021] B. Film layer B formed from a composition B comprising at least one isocyanate; and wherein film layer A is in contact with film layer B.

[0022] In one embodiment, the invention is a multilayer film according to any one or more of the embodiments described herein, and wherein the film consists essentially of layer A and layer B.

[0023] In a specific embodiment, the film layer...

Embodiment 1

[0167] The binder was diluted to approximately 40% solids with ethyl acetate. The adhesive was applied to the foil side of a "PET / Al prelaminate" sheet (approximately 20x30 cm) using a wire wound rod. A strip of paper 5 cm wide and 20 cm long was placed across the center of the sheet to provide an unlaminated strip area for separation of the film for the peel test. The polyethylene film was corona treated and then laminated to the adhesive applied to the aluminum foil by applying pressure at about 180°F (82°C) using steel nip rolls. The laminate was placed between two steel plates and stored in a sealed vacuum drying oven containing anhydrous calcium sulfate desiccant and purged with dry nitrogen. Cut into 15 millimeter (mm) strips at the intervals specified in the table and test for T-peel adhesion on a Thwing Albert tester at a speed of 4 inches (10 cm) / min.

[0168] Table 1

[0169] Laminated structure of embodiment 1

[0170]

[0171] The isocyanate-terminated p...

Embodiment 2

[0182] Two-layer polyethylene films were prepared, one layer containing the catalyst or a mixture of catalyst and ATMER 100, and the other layer containing no additives. The aim is to have the additive concentrated enough to contact the side of the adhesive film. This allows for more efficient use of additives.

[0183] The PE film in this example has a two-layer structure, the outer layer contains a 33.3 volume percent (vol%) sealant layer, and the inner layer is pure DOWLEX 2045G polyethylene resin. The outer layer was prepared by dry blending DOWLEX 2045G polyethylene resin and an additive masterbatch (containing polyol or catalyst) at a certain blend ratio. Except that DOWLEX 2045G polyethylene resin was used instead of DOWLEX 5056NG polyethylene resin, the same method as in Example 1 was used to prepare the additive masterbatch. The additives used were FASCAT 9102 (butyltin tris(2-ethylhexanoate)) and ATMER 100.

[0184] Double layer PE film is produced by using Colin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com