Curing agent for waste incineration fly ash

A waste incineration fly ash and curing agent technology, applied in the field of environmental protection, can solve the problems of low pertinence of heavy metals, high volumetric expansion rate of solidified body, volatilization of toxic substances, etc., and achieve long-term treatment effect, good curing effect and strong light resistance and the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

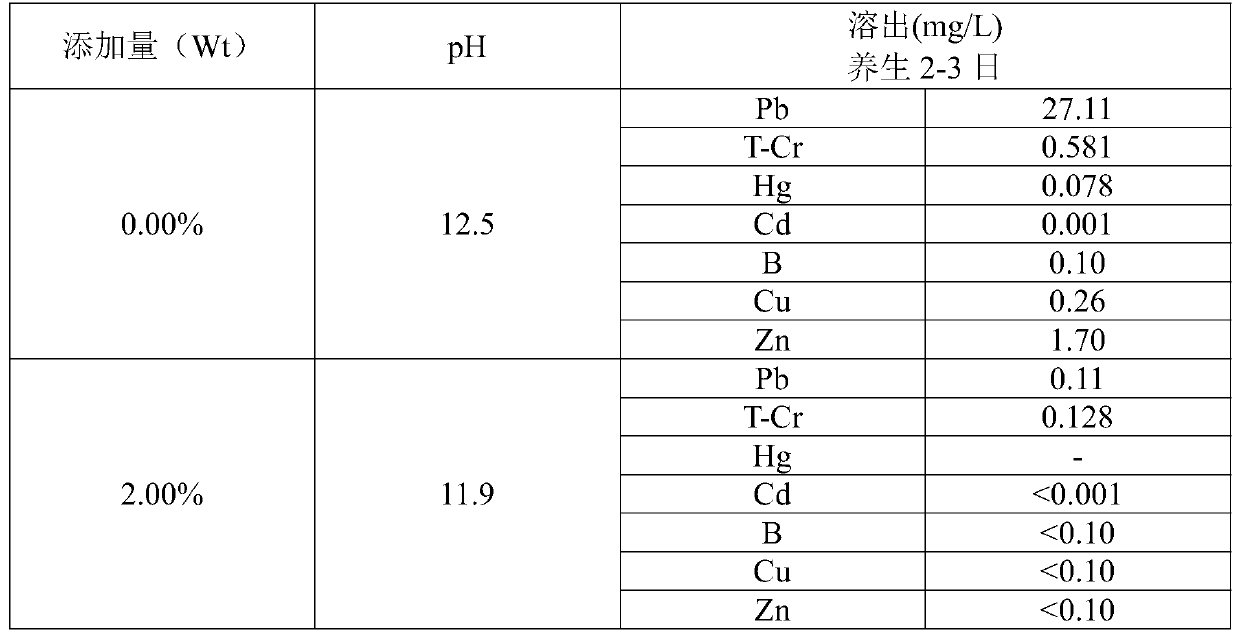

Examples

Embodiment 1

[0022] This embodiment provides a solidifying agent for waste incineration fly ash, which is prepared by mixing 80 parts of pyrite and 20 parts of calcium carbonate powder per 100 parts; the mass percent content of sulfur in the pyrite is 52% . According to the proportion, after the pyrite and calcium carbonate powder are fully ground and mixed, the required curing agent can be obtained.

Embodiment 2

[0024] This embodiment provides a solidifying agent for waste incineration fly ash, which is prepared by mixing 85 parts of pyrite and 15 parts of calcium carbonate powder per 100 parts; the mass percent content of sulfur in the pyrite is 48% . According to the proportion, after the pyrite and calcium carbonate powder are fully ground and mixed, the required curing agent can be obtained.

Embodiment 3

[0026] This embodiment provides a solidifying agent for waste incineration fly ash, which is prepared by mixing 90 parts of pyrite and 10 parts of calcium carbonate powder per 100 parts; the mass percentage content of sulfur in the pyrite is 48% . According to the proportion, after the pyrite and calcium carbonate powder are fully ground and mixed, the required curing agent can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com