Cyanidation tailing solidification agent and application of solidification agent

A technology for cyanidation tailings and curing agent, applied in the field of curing agent for cyanide tailings and hazardous solid waste curing treatment, can solve the problems of high cost and difficult composition of curing agent, achieve good curing effect, improve curing and stability Control effect, promote dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

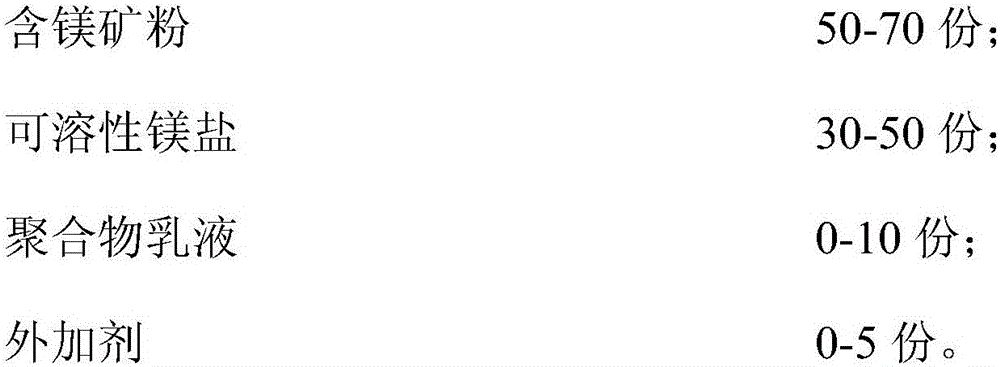

Method used

Image

Examples

Embodiment 1

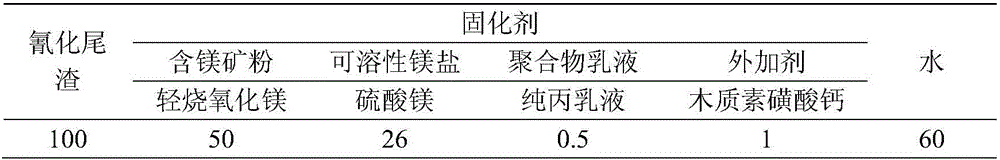

[0044] In terms of parts by mass, Table 1 shows the components of the cyanide tailings curing agent and the ratio of the curing agent to the cyanide tailings solidified body.

[0045] Table 1

[0046]

[0047] Applying the cyanide tailings curing agent to solidify the cyanide tailings comprises the following steps:

[0048] (1) Dissolve 26 parts of magnesium sulfate, 0.5 parts of pure acrylic emulsion, 1.0 part of calcium lignosulfonate and 60 parts of water in a stirring container, mix and stir for 2 minutes to obtain a mixed solution;

[0049] (2) 100 parts of cyanide tailings are added in the stirring vessel and mixed with the mixed solution obtained in step (1) and then stirred, the stirring time is 20min, and the mixed slurry is obtained;

[0050] (3) Add 50 parts of light-burned magnesium oxide into the mixed slurry obtained in step (2) and mix, continue to stir, and the stirring time is 8min to obtain the mixed material;

[0051] (4) The mixture obtained in step (3...

Embodiment 2

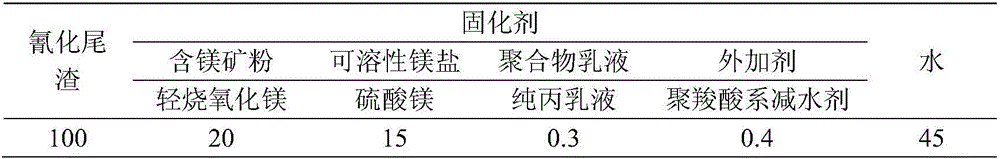

[0054] In terms of parts by mass, Table 2 shows the components of the cyanide tailings curing agent and the ratio of the curing agent to the cured cyanide tailings body.

[0055] Table 2

[0056]

[0057] Applying the cyanide tailings curing agent to solidify the cyanide tailings comprises the following steps:

[0058] (1) Dissolve 15 parts of magnesium sulfate, 0.3 parts of pure acrylic emulsion, 0.4 parts of polycarboxylate water reducer and 45 parts of water in a stirring container, and mix and stir for 2 minutes to obtain a mixed solution;

[0059] (2) 100 parts of cyanide tailings are added in the stirring vessel and mixed with the mixed solution obtained in step (1) and then stirred, the stirring time is 20min, and the mixed slurry is obtained;

[0060] (3) Add 20 parts of light-burned magnesium oxide into the mixed slurry obtained in step (2) and mix, continue to stir, and the stirring time is 8min to obtain the mixed material;

[0061] (4) Place the mixture obtain...

Embodiment 3

[0064] In terms of parts by mass, Table 3 shows the components of the cyanide tailings curing agent and the ratio of the curing agent to the cyanide tailings solidified body.

[0065] table 3

[0066]

[0067] Applying the cyanide tailings curing agent to solidify the cyanide tailings comprises the following steps:

[0068] (1) Dissolve 25 parts of magnesium chloride, 0.5 parts of styrene-acrylic emulsion, 0.4 parts of polycarboxylate water reducer and 50 parts of water in a stirring container, and mix and stir for 3 minutes to obtain a mixed solution;

[0069] (2) 100 parts of cyanide tailings are added in the stirring container and mixed with the mixed solution obtained in step (1) and then stirred, and the stirring time is 25min to obtain the mixed slurry;

[0070] (3) Add 40 parts of brucite powder into the mixed slurry obtained in step (2) and mix, continue to stir, and the stirring time is 7.5min to obtain the mixed material;

[0071] (4) Place the mixture obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com