Heavy metal normal temperature solidifier and method for solidifying heavy metal in heavy metal pollutant by using heavy metal normal temperature solidifier

A technology of room temperature solidification and heavy metals, applied in the field of heavy metal pollutant treatment, can solve the problems of high room temperature solidification cost, secondary pollution solidifying agent dosage, etc., and achieve good solidification effect, good removal effect, and increase the effect of adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

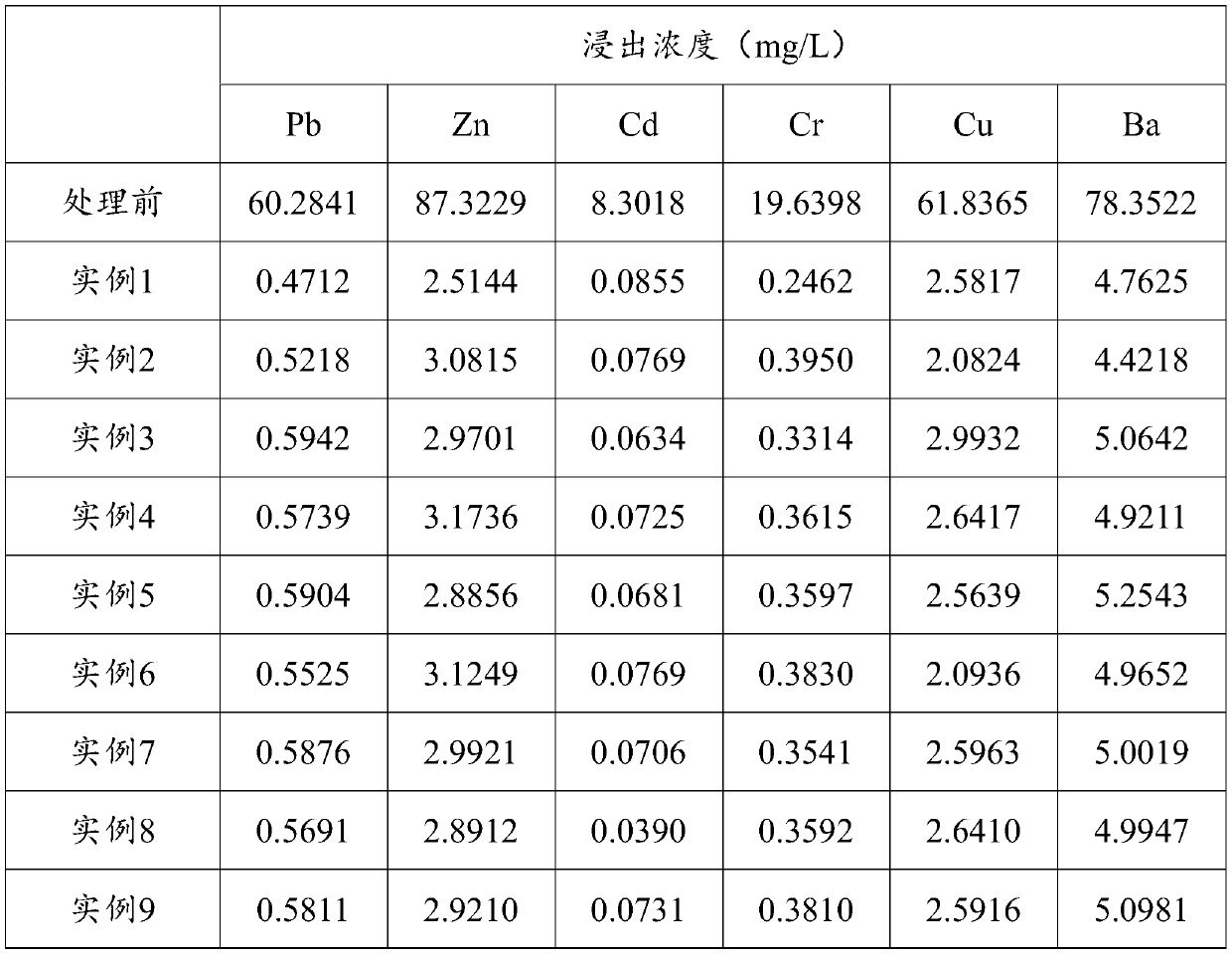

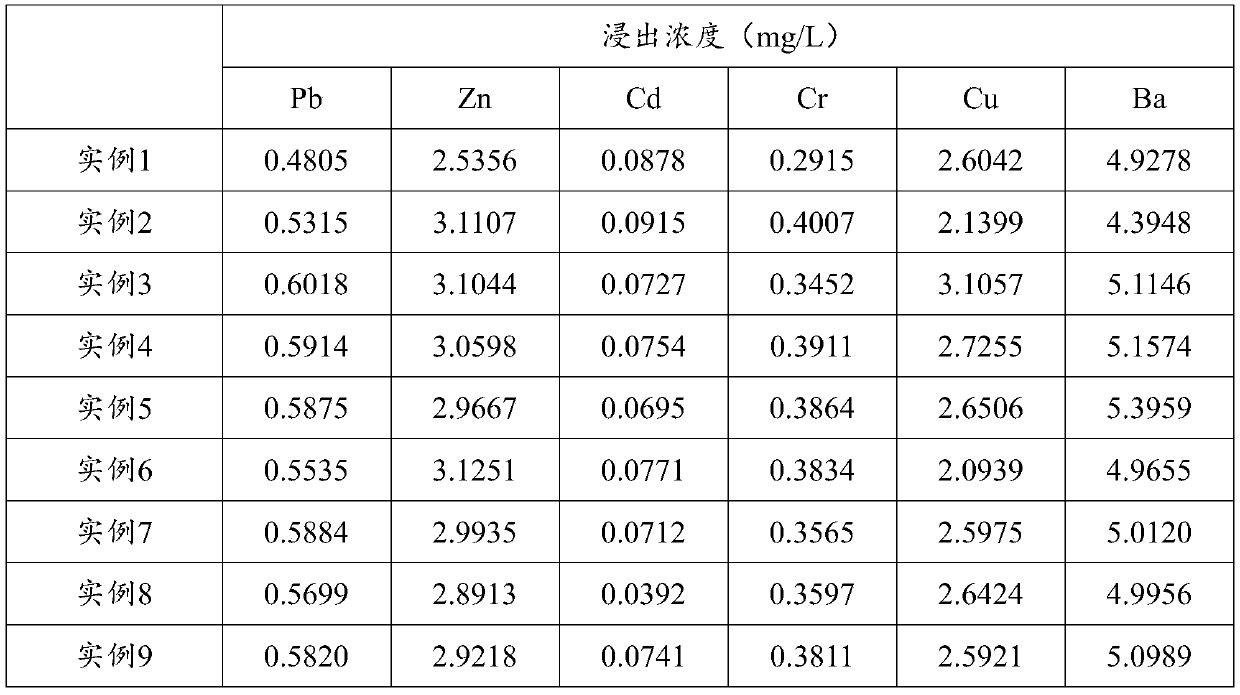

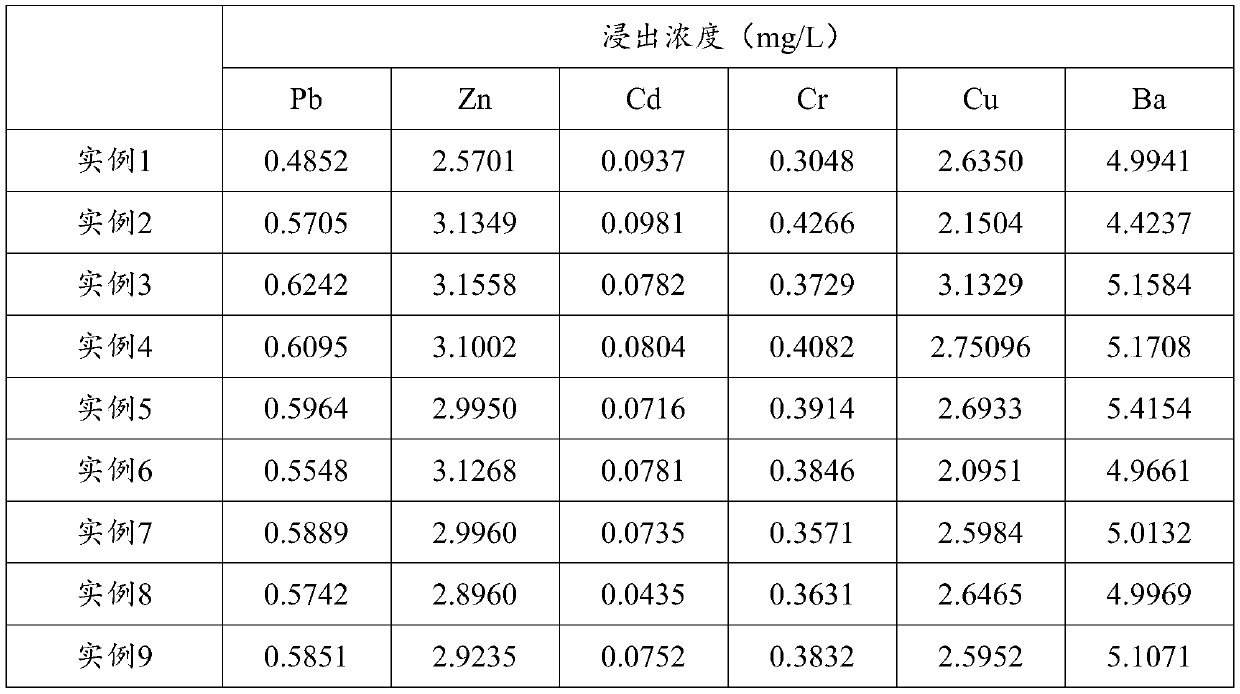

Examples

example 1

[0052] The heavy metal normal temperature curing agent raw material weight composition that this example adopts is:

[0053] 5 parts of nano molecular sieve, 10 parts of calcium oxide, 7 parts of aluminum sulfate, 3 parts of iron oxide.

[0054] Wherein the nano molecular sieve is a Y type molecular sieve.

[0055] Then, the heavy metal normal temperature curing agent is used to cure the heavy metals in the heavy metal pollutants provided in this embodiment, which specifically includes the following steps:

[0056] Step 1. Mix the heavy metal pollutants and the heavy metal normal temperature curing agent evenly at normal temperature to obtain a mixture, wherein the mass ratio of the heavy metal pollutants to the heavy metal normal temperature curing agent is 100:15, and the water content of the mixture is 3%;

[0057] Step 2. The mixture prepared in step 1 was left to stand for 60 hours at normal temperature;

[0058] Step 3. The mixture treated in step 2 is mixed with water...

example 2

[0060] The heavy metal normal temperature curing agent raw material weight composition that this example adopts is:

[0061] 1 part of nano molecular sieve, 5 parts of calcium oxide, 30 parts of aluminum sulfate, 1 part of iron oxide.

[0062] Wherein the nano molecular sieve is a Y type molecular sieve.

[0063] Then, the heavy metal normal temperature curing agent is used to cure the heavy metals in the heavy metal pollutants provided in this embodiment, which specifically includes the following steps:

[0064] Step 1. Mix the heavy metal pollutants and the heavy metal normal temperature curing agent evenly at normal temperature to obtain a mixture, wherein the mass ratio of the heavy metal pollutants to the heavy metal normal temperature curing agent is 100:20, and the water content of the mixture is 5%;

[0065] Step 2. The mixture prepared in step 1 was left to stand for 72 hours at normal temperature;

[0066] Step 3. Add water to the mixture treated in step 2 and mix ...

example 3

[0068] The heavy metal normal temperature curing agent raw material weight composition that this example adopts is:

[0069] 3 parts of nano molecular sieve, 3 parts of calcium oxide, 10 parts of aluminum sulfate, 5 parts of iron oxide.

[0070] Wherein the nano molecular sieve is a Y type molecular sieve.

[0071] Then, the heavy metal normal temperature curing agent is used to cure the heavy metals in the heavy metal pollutants provided in this embodiment, which specifically includes the following steps:

[0072] Step 1. Mix the heavy metal pollutants and the heavy metal normal temperature curing agent evenly at normal temperature to obtain a mixture, wherein the mass ratio of the heavy metal pollutants to the heavy metal normal temperature curing agent is 100:30, and the water content of the mixture is 4%;

[0073] Step 2. The mixture prepared in step 1 was left to stand for 48 hours at room temperature;

[0074] Step 3. Add water to the mixture treated in step 2 and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com