Harmless disposal method for high-arsenic heavy metal sludge

A technology of heavy metal sludge and disposal method, which is applied in sludge treatment, chemical instruments and methods, fixed/solidified sludge treatment, etc. It can solve the problems of unstable leaching toxicity and high cost, and achieve good solidification effect and good storage conditions. The effect of relaxation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

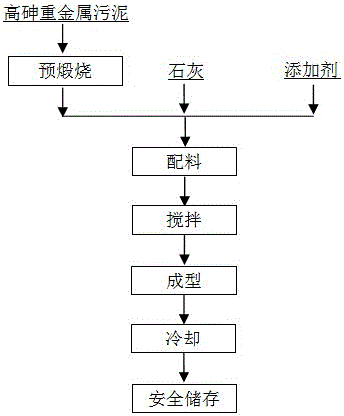

[0021] Such as figure 1 As shown, the specific steps of the harmless disposal method of high-arsenic heavy metal sludge are as follows:

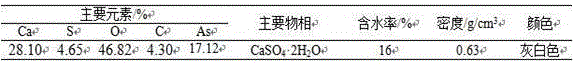

[0022] (1) Pre-calcining: First, the moisture content <40% high arsenic heavy metal sludge (the main physical and chemical properties of high arsenic heavy metal sludge are shown in Table 1 and the leaching toxicity is shown in Table 2), pre-calcined at a temperature of 300°C for 3 hours to obtain a calcined product;

[0023] Table 1

[0024]

[0025] (2) Ingredients: Add additives and lime to the calcined product obtained in step (1) according to a mass ratio of 80:12:8 to obtain a mixture; wherein the additives are two with a mass ratio of 40:20:20:10:10 Silicon oxide powder, bismuth trioxide (Bi 2 O 3 ), boron oxide (B 2 O 3 ), calcium oxide (CaO) and zinc oxide (ZnO) mixture; use planetary mixer for stirring;

[0026] (3) The mixture material obtained in step (3) is molded to produce a solidified body, which is stored safely after cooling; the ...

Embodiment 2

[0032] Such as figure 1 As shown, the specific steps of the harmless disposal method of high-arsenic heavy metal sludge are as follows:

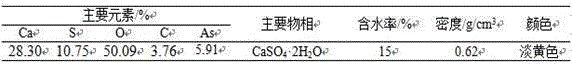

[0033] (1) Pre-calcining: First, the moisture content <40% high arsenic heavy metal sludge (the main physical and chemical properties of high arsenic heavy metal sludge are shown in Table 3 and the leaching toxicity is shown in Table 4), pre-calcined at a temperature of 250℃ for 2h to obtain a calcined product;

[0034] table 3

[0035]

[0036] (2) Ingredients: Add additives and lime to the calcined product obtained in step (1) at a mass ratio of 75:17:8 to obtain a mixture material; where the additive is a mass ratio of 20:40:20:10:10 dioxide Silicon powder, bismuth trioxide (Bi 2 O 3 ), boron oxide (B 2 O 3 ), calcium oxide (CaO) and zinc oxide (ZnO) mixture; use planetary mixer for stirring;

[0037] (3) The mixture material obtained in step (3) is molded to produce a solid body, which is cooled and stored safely; in step (3), it is molded by h...

Embodiment 3

[0043] Such as figure 1 As shown, the specific steps of the harmless disposal method of high-arsenic heavy metal sludge are as follows:

[0044] (1) Pre-calcining: First, the moisture content <40% high arsenic heavy metal sludge (the main physical and chemical properties of high arsenic heavy metal sludge are shown in Table 5 and the leaching toxicity is shown in Table 6), pre-calcined at a temperature of 250°C for 1 hour to obtain a calcined product;

[0045] table 5

[0046]

[0047] (2) Ingredients: Add additives and lime to the calcined product obtained in step (1) according to the mass ratio of 70:20:10 to obtain a mixture material; where the additive is a mass ratio of 20:20:40:10:10 dioxide Silicon powder, bismuth trioxide (Bi 2 O 3 ), boron oxide (B 2 O 3 ), calcium oxide (CaO) and zinc oxide (ZnO) mixture; use planetary mixer for stirring;

[0048] (3) The mixture material obtained in step (3) is molded to produce a solidified body, which is stored safely after cooling; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com