Composite acrylic transparent film, and preparation method and application thereof

A technology for compounding acrylic and transparent films, used in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of compound layer thickness, poor weather resistance, poor light transmission effect, etc. Effects of excellent gloss and reflection, good outdoor weatherability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

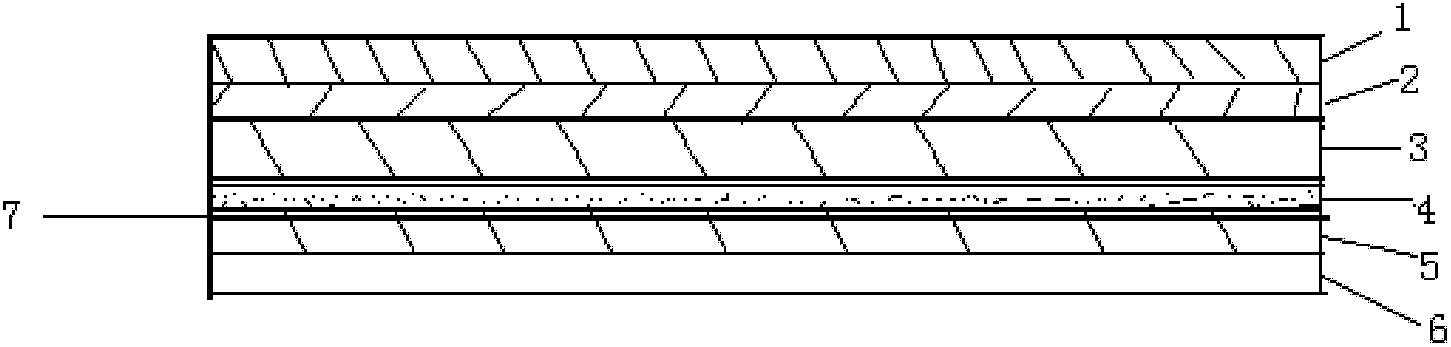

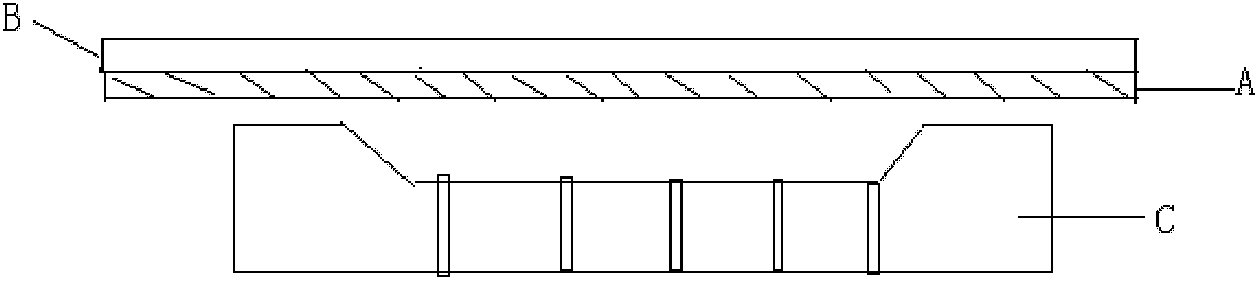

[0029] Such as figure 1 Shown, composite acrylic transparent film of the present invention comprises from top to bottom:

[0030] Protective layer: a transparent protective film 1 with a thickness of 36um ~ 100um (micron) (PET, PP or PE material can be used), with a layer of low-viscosity removable sensitive adhesive 2 under it, and the thickness of the low-viscosity removable sensitive adhesive 2 5-10um, the peeling force is 5-10 g / inch, and the low-viscosity removable sensitive adhesive 2 can be purchased from Ashland Chemical Company 1452;

[0031] The transparent acrylic film 3 adopts a transparent acrylic film 3 with a thickness between 75 and 100um, which can be purchased on the market, including but not limited to the Flexiplas series of acrylic films from evonik;

[0032] Plating layer: that is, the metal deposition layer 4, the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com