High-thermal-conductivity film as well as preparation method and application thereof

A high thermal conductivity, thin film technology, applied in the direction of modification, cooling/ventilation/heating transformation by conduction heat transfer, etc., can solve the problems of environmental degradation, low thermal conductivity of coatings, aggravated greenhouse gas emissions, etc., to improve scattering efficiency, The effect of high sunlight reflectivity and thermal conductivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

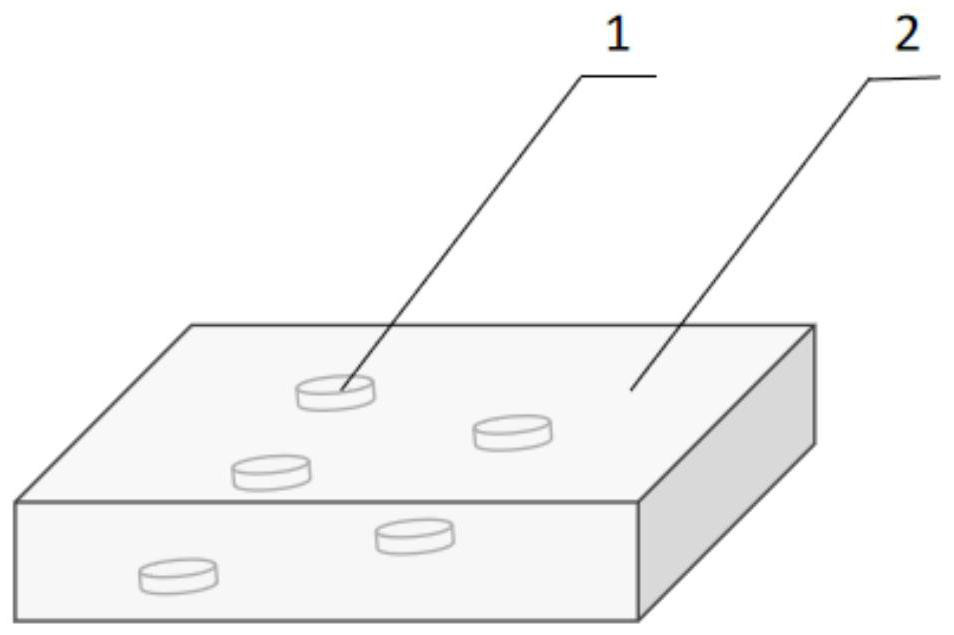

[0040] In a second aspect, the present invention provides a method for preparing the high thermal conductivity film, comprising the steps of:

[0041] Disperse the photonic structure nanosheets into an organic solvent to obtain a suspension;

[0042] Add organic polymer main agent and crosslinking agent to the suspension, and mix well to obtain a composite solution;

[0043] The prepared composite solution is cast into a wet film;

[0044] The wet film is cured and dried into a film.

[0045] In some embodiments, the organic solvent is ethanol or cyclohexane.

[0046] In some embodiments, the organic polymer main agent is polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA), polycarbonate (PC), polyvinylidene fluoride (PVDF) or One or more of polyethylene terephthalate (PET); the crosslinking agent is dimethylaminopropylamine or diethylaminopropylamine, etc.

[0047] Preferably, the time for continuous stirring once is 0.8-1.2h, the time for ultrasonic treatment is 0...

Embodiment 1

[0054] The preparation method of high thermal conductivity thin film, comprises the steps:

[0055] Step 1: Dispersion of Photonic Structured Nanosheets:

[0056] Add the photon-structured nanosheets into a beaker with an organic solvent and seal it, stir it with a magnetic stirrer at room temperature for 1 hour, then put the beaker into an ultrasonic cleaner, and ultrasonicate for 1 hour at room temperature to obtain uniform dispersion of photon-structured nanosheets of the suspension.

[0057] Step 2: Preparation of organic polymer-nanophotonic structure composite solution:

[0058]Add a certain proportion of organic polymer main agent to the uniformly dispersed suspension, place the beaker on a magnetic stirrer and stir for 1 hour at room temperature, and then place it in an ultrasonic cleaner for 1 hour of ultrasonication. After the ultrasound is over, uncover the sealing cover above the beaker, re-place it on a magnetic stirrer and stir for 30 minutes, then add 3wt% of ...

Embodiment 2

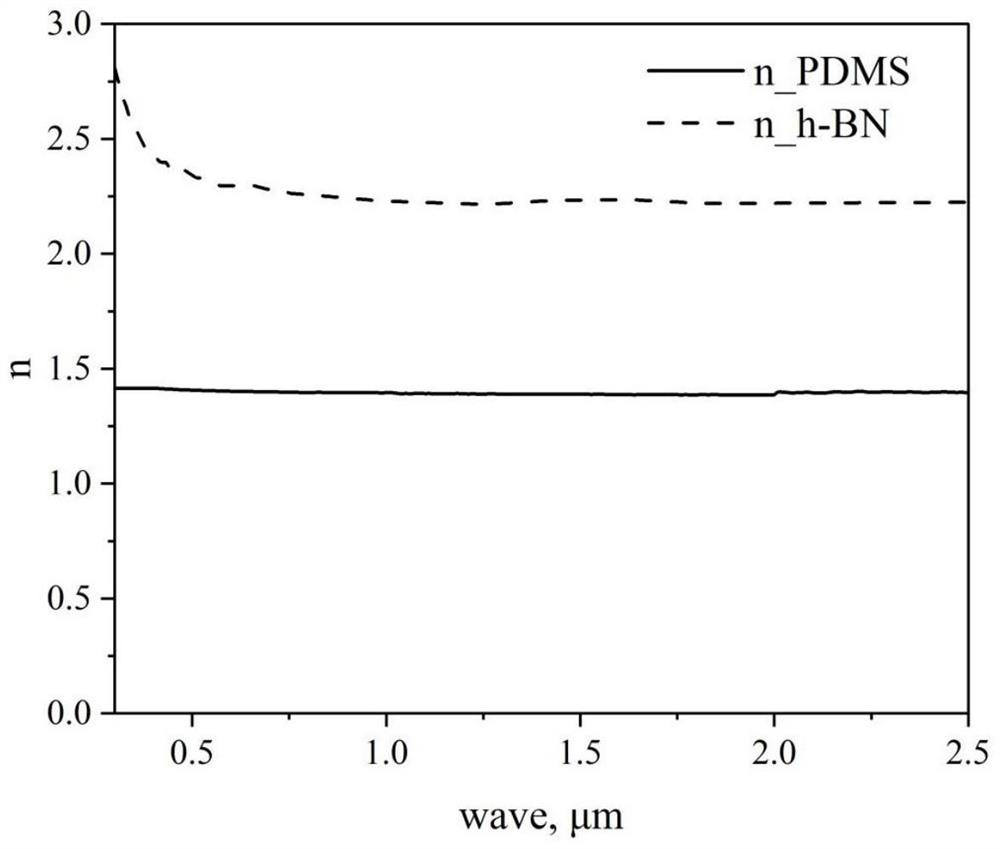

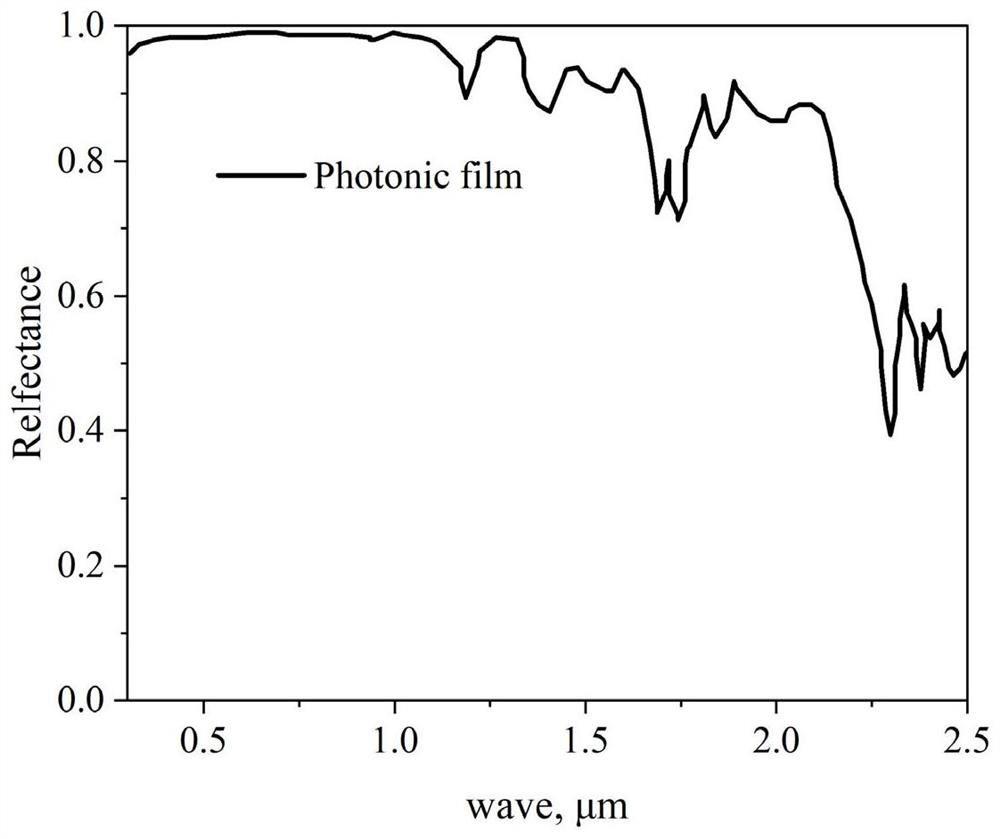

[0070] The preparation method of the high thermal conductivity film is the same as that of Example 1. A two-dimensional h-BN scatterer with a wide band gap, high refractive index and high backscattering efficiency is introduced into the polymethyl methacrylate flexible matrix. The film has good Subambient radiative cooling performance comparable to existing photonic structures. The thickness of the film is 200 μm, and the size of h-BN nanosheets is 300 nm.

[0071] The mass concentration of h-BN nanosheets in the high thermal conductivity film is 30%, and the high thermal conductivity film exhibits a reflectivity of 94% in the wavelength range of 0.3-2.5 μm, and a high infrared (IR) emissivity of up to 0.87.

[0072] The thermal conductivity of the composite material mixed with 70% PMMA matrix and 30% h-BN particles is about 73.08Wm -1 K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com