Pigment-type UV curable coating for window film and preparation method of pigment-type UV curable coating

An ultraviolet light and pigment technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of window film fading, unsightly appearance, expensive dyes, etc., to ensure compatibility and improve coating process performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

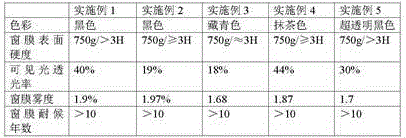

Embodiment 1

[0048] This embodiment provides an ultraviolet photocurable coating for protective color window film, which is prepared by the following preparation method:

[0049] 33 parts by mass of acrylate monomers including dipropylene glycol diacrylate, 3 parts by mass of isobornyl methacrylate, 4 parts by mass of carbon black, and 0.3 parts by mass of amino acid ester copolymer (Koring P61) were mixed and ground for 180 minutes, filtered, and left Under the slurry.

[0050] The slurry was mixed with 35 parts by mass of amine-modified urethane acrylate, 4 parts by mass of 2-hydroxy-methylphenylpropane-1-one, 0.6 parts by mass of γ-aminopropyltriethoxysilane, and 0.8 parts by mass of polyether The modified silicone is put into a stirring tank for stirring and mixing to obtain a finished coating product of a pigment-type protective color UV-curable window film.

[0051] The paint obtained by the invention does not fade when exposed to sunlight under the premise of ensuri...

Embodiment 2

[0053] This embodiment provides a kind of ultraviolet photocurable coating for protective color window film, which is prepared by the following method:

[0054] With 2 mass parts of hydroxypropyl acrylate, 29 mass parts of pentaerythritol triacrylate, 20 mass parts of 2-butoxymethylethyl-1,3-propanediyl-2-acrylate and 8 mass parts of carbon black, Put 0.6 parts by mass of high molecular polymer (Deqian DP983) into a grinding tank and grind for 180 minutes, filter to obtain a slurry; put the slurry and 30 parts by mass of acrylic modified polyurethane (Jiangsu Sanmu SM-60217) into a stirring tank Stir for 30 minutes; put 0.05 parts by mass of polyether-polyester modified polysiloxane (Digo 410) and γ-aminopropyltriethoxysilane (Jessica HK550) into the stirring tank and stir for 20 minutes. Finally, 5 parts by weight of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide was added and stirred for 15 minutes to obtain a finished ultraviolet photocurable coating for protective color wi...

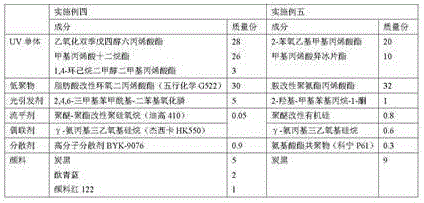

Embodiment 3

[0057] This embodiment provides a kind of ultraviolet photocurable coating for protective color window film, which is prepared by the following method:

[0058] 3 parts by mass of aliphatic polyurethane diacrylate, 27 parts by mass of isobornyl acrylate, 30 parts by mass of trimethylolpropane diacrylate, 6 parts by mass of carbon black, 3 parts by mass of phthalocyanine blue 15 : 4, 0.8 parts by mass of polymer dispersant BYK-9076 was put into a grinding kettle and ground for 160min, filtered to obtain a slurry; the slurry and 27 parts by mass of fatty acid modified epoxy diacrylate (Wuxing Chemical G522) Put it into the stirring tank and stir for 30 minutes; put 0.05 parts by mass of polyether-polyester modified polysiloxane (Digo 410) and γ-aminopropyltriethoxysilane (Jessica HK550) into the stirring tank Stir for 20 minutes, and finally add 5 parts by weight of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and stir for 15 minutes to obtain a finished UV photocurable coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com