Acid rain resistant flexible outer wall emulsion paint

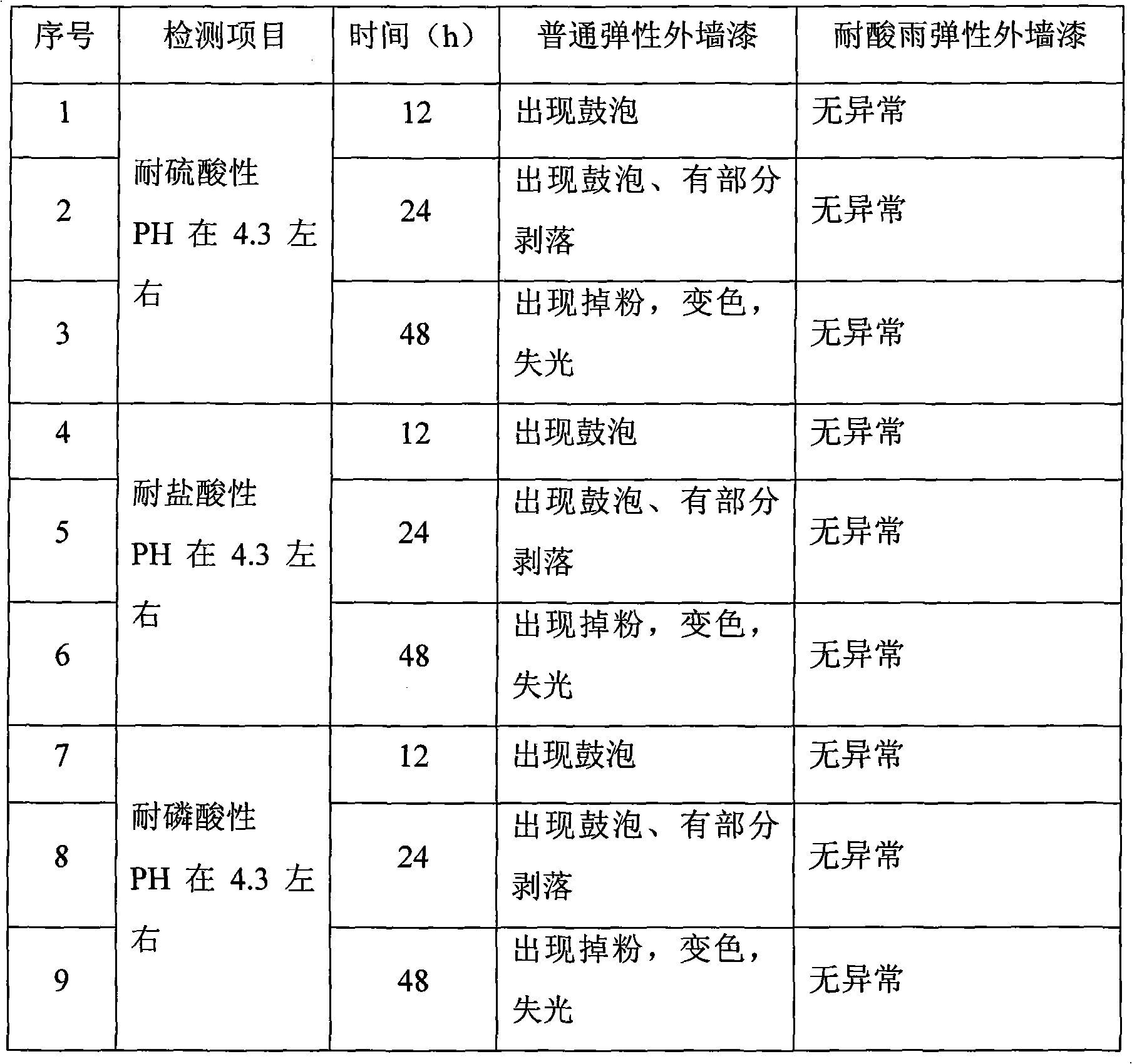

An elastic exterior wall, latex paint technology, applied in latex paint, coating and other directions, can solve the problem of paint being easily corroded by acid rain, easy to crack, peel off, etc., to achieve excellent outdoor weather resistance, good low temperature elasticity, excellent waterproof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

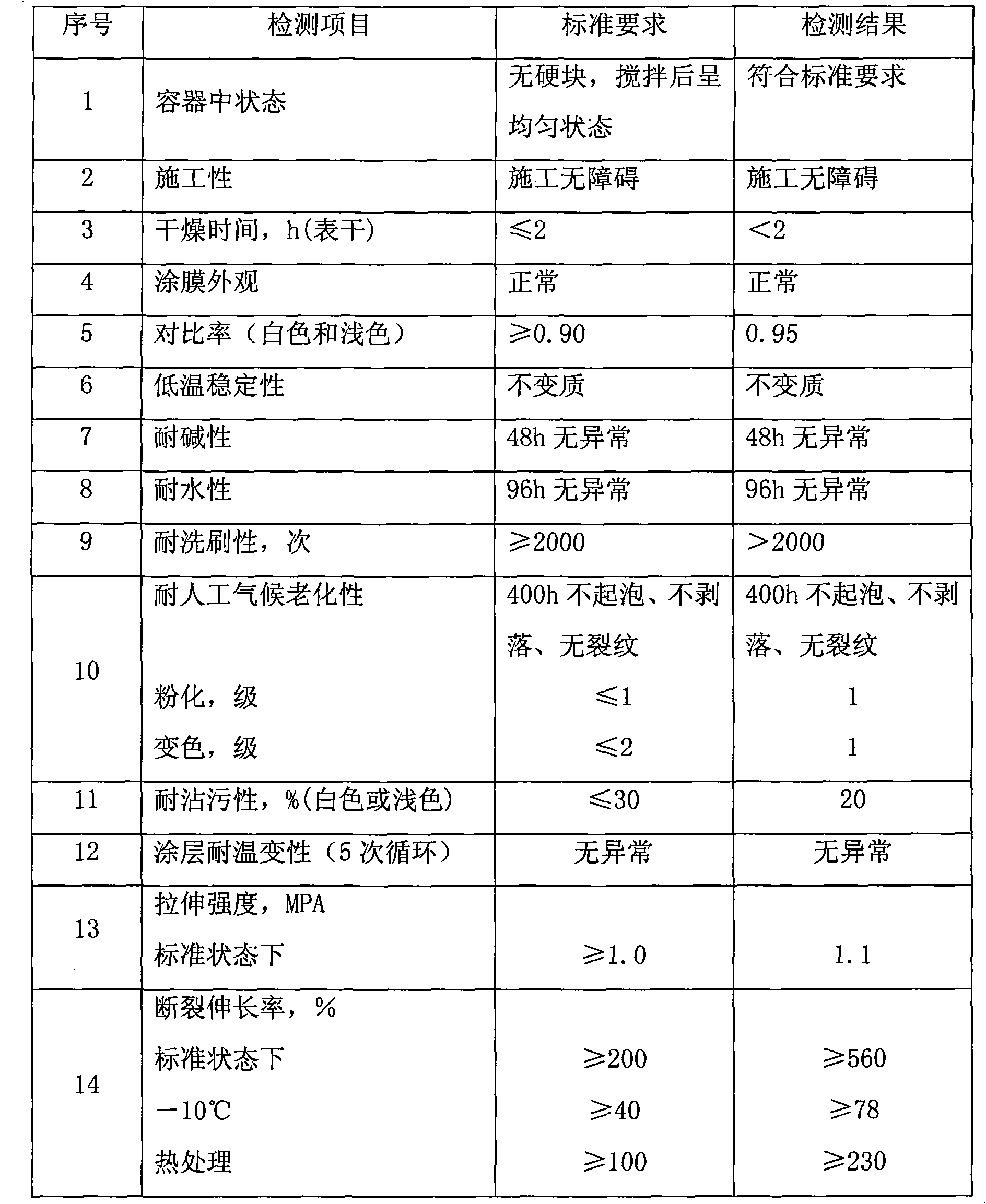

Examples

Embodiment 1

[0035] Example 1: Acid rain resistant elastic exterior wall latex paint white paint

[0036] Weigh 17.0 parts of water based on 100 parts by weight, and add dispersant 5027: 0.7 parts, thickener NATROSAL 250HBR: 0.15 parts, and wetting agent PE-100: 0.1 parts at a speed of 300-600 rpm , 1.0 parts of propylene glycol, defoamer 0.5 parts, disperse for 5 minutes; put in rutile titanium dioxide at 600-1000 rpm 20.0 parts, filler superfine barium sulfate: 18.0 parts; at 1000-1300 rpm, disperse for 20-30 minutes; quality inspection sampling inspection fineness ≤ 60 microns; at 300-600 rpm, sequentially Add film-forming aid TEAXNAL: 1 part, preservative Kathon TM LXE: 0.2 parts, antifungal agent 0.6 parts, disperse for 5 minutes, and then add elastic emulsion Elastene TM 2468: 40 parts, PH regulator AMP-95: 0.1 part, defoamer 0.2 parts, thickener ACRYSOL RM-8W: 0.45 parts, dispersed for 5 minutes; quality inspection sampling inspection; filter and pack after passing.

Embodiment 2

[0037] Embodiment 2: acid rain resistant elastic exterior wall latex paint white paint (without adding film-forming aids)

[0038] Weigh 18.0 parts of water based on 100 parts by weight, and add dispersant 5027: 0.7 parts, thickener NATROSAL 250HBR: 0.15 parts, wetting agent PE-100: 0.1 parts at a speed of 300-600 rpm , 1.0 parts of propylene glycol, defoamer 0.5 parts, disperse for 5 minutes; put in rutile titanium dioxide at 600-1000 rpm 20.0 parts, filler superfine barium sulfate: 18.0 parts; at 1000-1300 rpm, disperse for 20-30 minutes; quality inspection sampling inspection fineness ≤ 60 microns; at 300-600 rpm, sequentially Add film-forming aid TEAXNAL: 0 parts, preservative Kathon TM LXE: 0.2 parts, antifungal agent 0.6 parts, disperse for 5 minutes, and then add elastic emulsion Elastene TM2468: 40 parts, PH regulator AMP-95: 0.1 part, defoamer 0.2 parts, thickener ACRYSOL RM-8W: 0.45 parts, dispersed for 5 minutes; quality inspection sampling inspection; fil...

Embodiment 3

[0039] Embodiment 3: acid rain resistant elastic exterior wall latex paint transparent varnish

[0040] Weigh 20.0 parts of water based on 100 parts by weight, and add dispersant 5027: 0.6 parts, thickener NATROSAL 250HBR: 0.25 parts, wetting agent PE-100: 0.1 parts at a speed of 300-600 rpm , 1.5 parts of propylene glycol, defoamer 0.5 parts, disperse for 5 minutes; put in rutile titanium dioxide at 600-1000 rpm 0.0 parts, filler superfine barium sulfate: 20.0 parts; at 1000-1300 rpm, disperse for 20-30 minutes; quality inspection sampling inspection fineness ≤ 60 microns; at 300-600 rpm, sequentially Add film-forming aid TEAXNAL: 1.2 parts, preservative Kathon TM LXE: 0.2 parts, antifungal agent 0.6 parts, disperse for 5 minutes, and then add elastic emulsion Elastene TM 2468: 54 parts, PH regulator AMP-95: 0.1 parts, defoamer 0.3 parts, thickener ACRYSOL RM-8W: 0.65 parts, dispersed for 5 minutes; quality inspection sampling inspection; filter and pack after passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com