Ultra-durable three-dimensional metal wiredrawing effect coating and production method thereof

A technology of metal wire drawing and production method, which is applied in the direction of coating, powder coating, anti-corrosion coating, etc., can solve the problems of no metal flickering feeling, narrow color selection range, and no three-dimensional effect of coating appearance, so as to achieve wide promotion and application value, Excellent anti-corrosion performance, colorful three-dimensional metal flashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The components and mass percentages of an ultra-durable, three-dimensional metal wire drawing effect coating are as follows:

[0073] Primer powder coating A 60%

[0074] Brushed Superfine Powder Coating B 20%

[0075] Transparent fluorocarbon water-based paint 20%

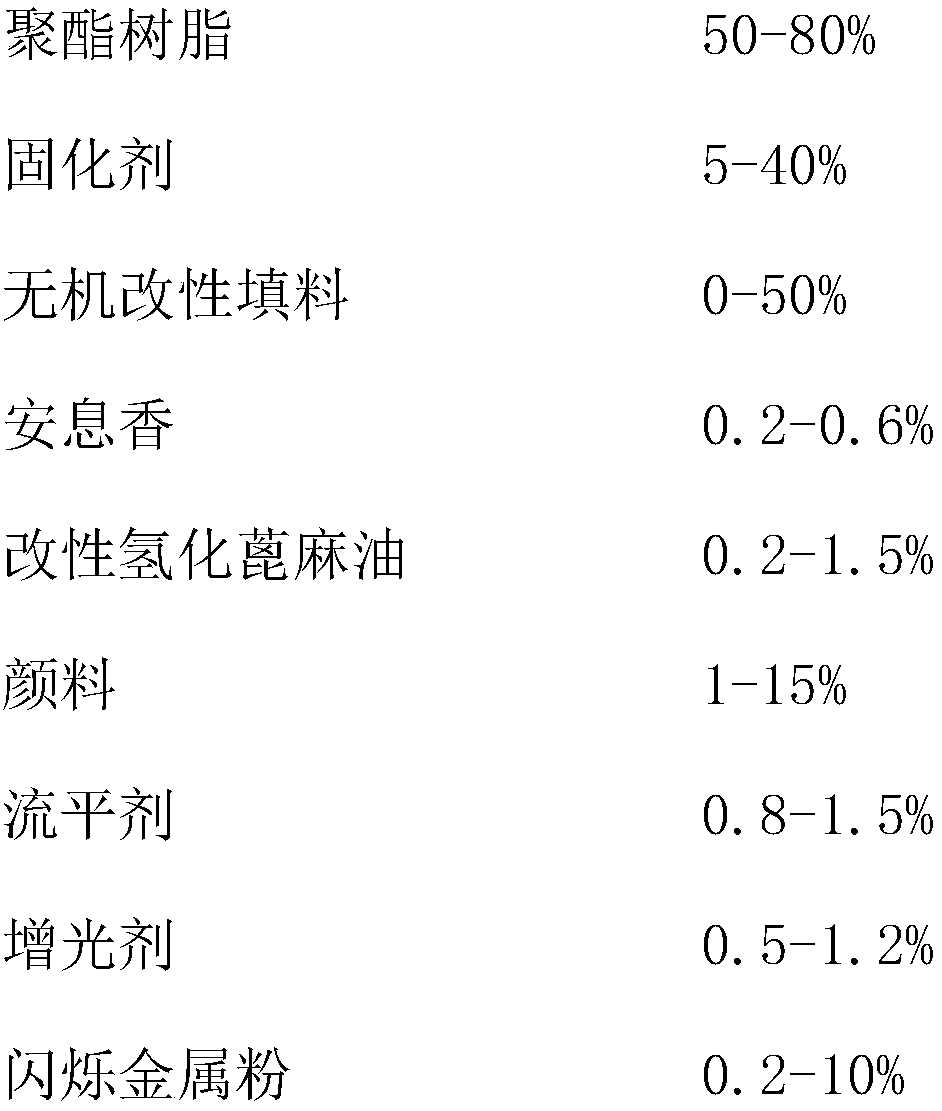

[0076] The components and mass percentages of the primer powder coating A of the above-mentioned super-durable, three-dimensional metal wire drawing effect coating are as follows:

[0077]

[0078] The production method of the primer powder coating A of the above-mentioned ultra-durable, three-dimensional metal wire drawing effect coating, comprises the following steps:

[0079] (1) All the ingredients are weighed according to the ratio, put into the mixing tank according to a reasonable order, mixed and crushed for 5-12 minutes;

[0080] (2) The material enters a twin-screw or single-screw extruder, the screw speed of the extruder is controlled at 300-500r / min, and the temperature is controlled at 11...

Embodiment 2

[0098] The components and mass percentages of an ultra-durable, three-dimensional metal wire drawing effect coating are as follows:

[0099] Primer powder coating A 60%

[0100] Brushed Superfine Powder Coating B 20%

[0101] Transparent fluorocarbon water-based paint 20%

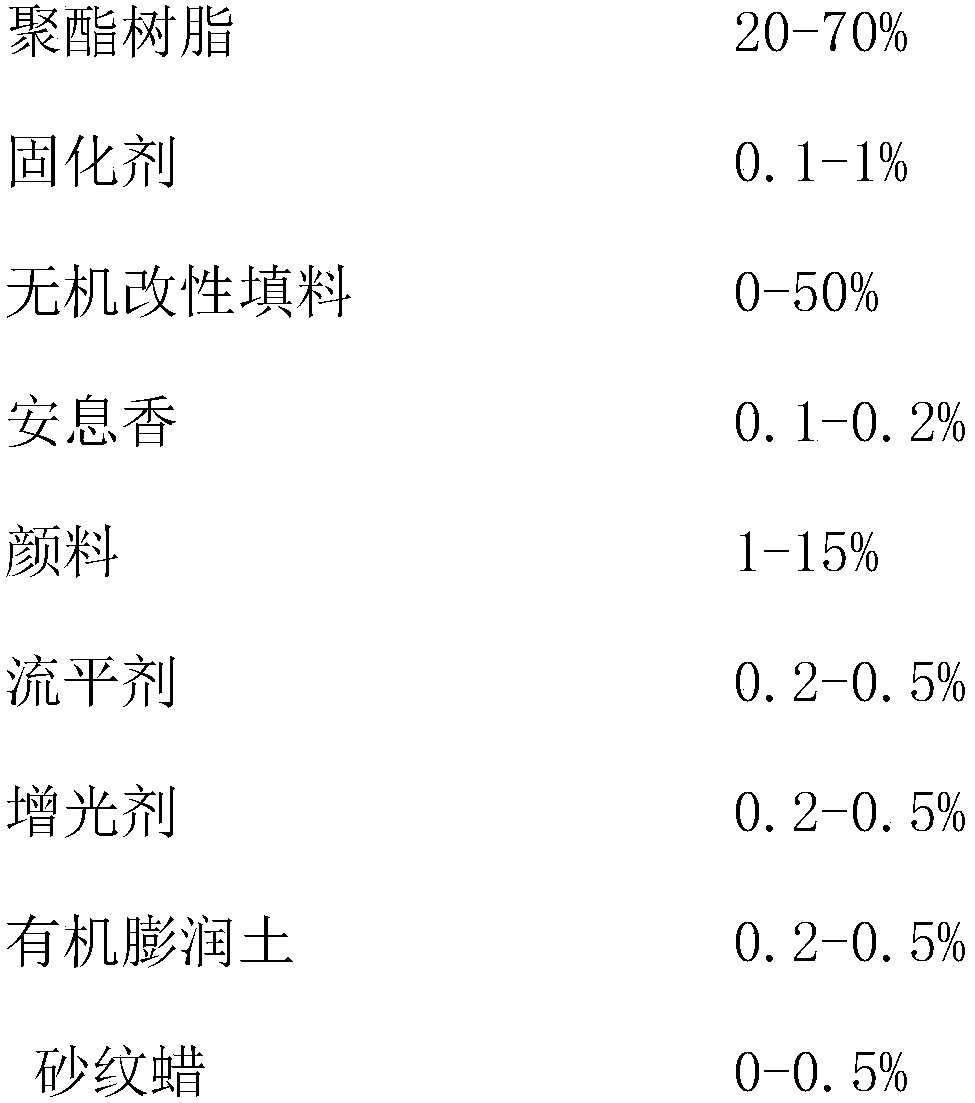

[0102] The components and mass percentages of the primer powder coating A of the above-mentioned super-durable, three-dimensional metal wire drawing effect coating are as follows:

[0103]

[0104] The production method of the primer powder coating A of the above-mentioned ultra-durable, three-dimensional metal wire drawing effect coating, comprises the following steps:

[0105] (1) All the ingredients are weighed according to the ratio, put into the mixing tank according to a reasonable order, mixed and crushed for 5-12 minutes;

[0106] (2) The material enters a twin-screw or single-screw extruder, the screw speed of the extruder is controlled at 300-500r / min, and the temperature is controlled at 11...

Embodiment 3

[0125] The components and mass percentages of an ultra-durable, three-dimensional metal wire drawing effect coating are as follows:

[0126] Primer powder coating A 60%

[0127] Brushed Superfine Powder Coating B 20%

[0128] Transparent fluorocarbon water-based paint 20%

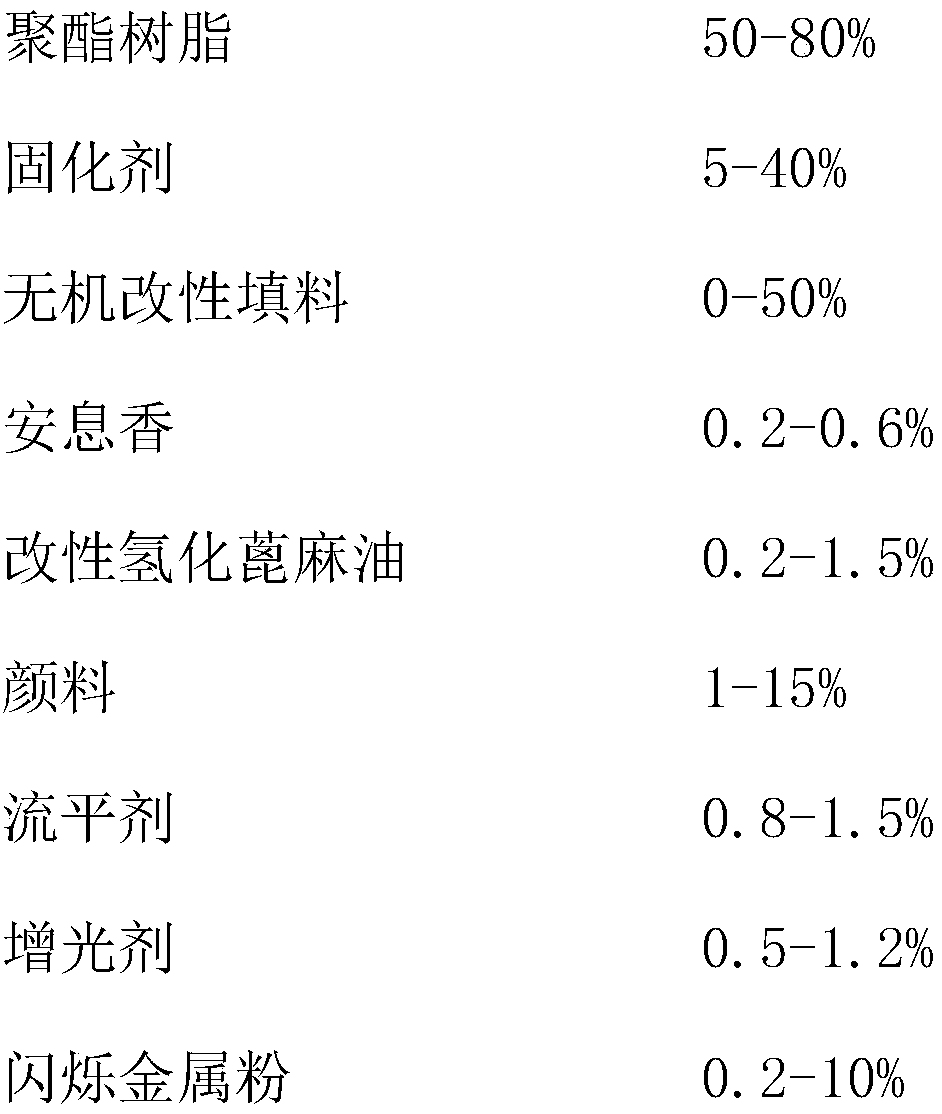

[0129] The components and mass percentages of the primer powder coating A of the above-mentioned super-durable, three-dimensional metal wire drawing effect coating are as follows:

[0130]

[0131] The production method of the primer powder coating A of the above-mentioned ultra-durable, three-dimensional metal wire drawing effect coating, comprises the following steps:

[0132] (1) All the ingredients are weighed according to the ratio, put into the mixing tank according to a reasonable order, mixed and crushed for 5-12 minutes;

[0133] (2) The material enters a twin-screw or single-screw extruder, the screw speed of the extruder is controlled at 300-500r / min, and the temperature is controlled at 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com