Method for preparing copper and chromium black pigment

A technology of copper chrome black and pigment, applied in the direction of fibrous filler, dyed polymer organic compound treatment, coating, etc., can solve the problems of unfavorable industrial production, high equipment requirements, long reaction time, etc. High reactivity, reducing the effect of ball milling process

Inactive Publication Date: 2011-08-17

邵阳县彩鑫制釉有限公司

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the particle size synthesized by these methods is relatively fine, there are disadvantages such as expensive raw materials required for synthesis, complex processes, high requirements for equipment, high temperature and high pressure during the reaction, and long reaction time, which are not conducive to realizing industrial production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] A total of 3 examples

[0010] Its raw material formula is:

[0011] Recipe:

[0012] Polyethylene glycol (g)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

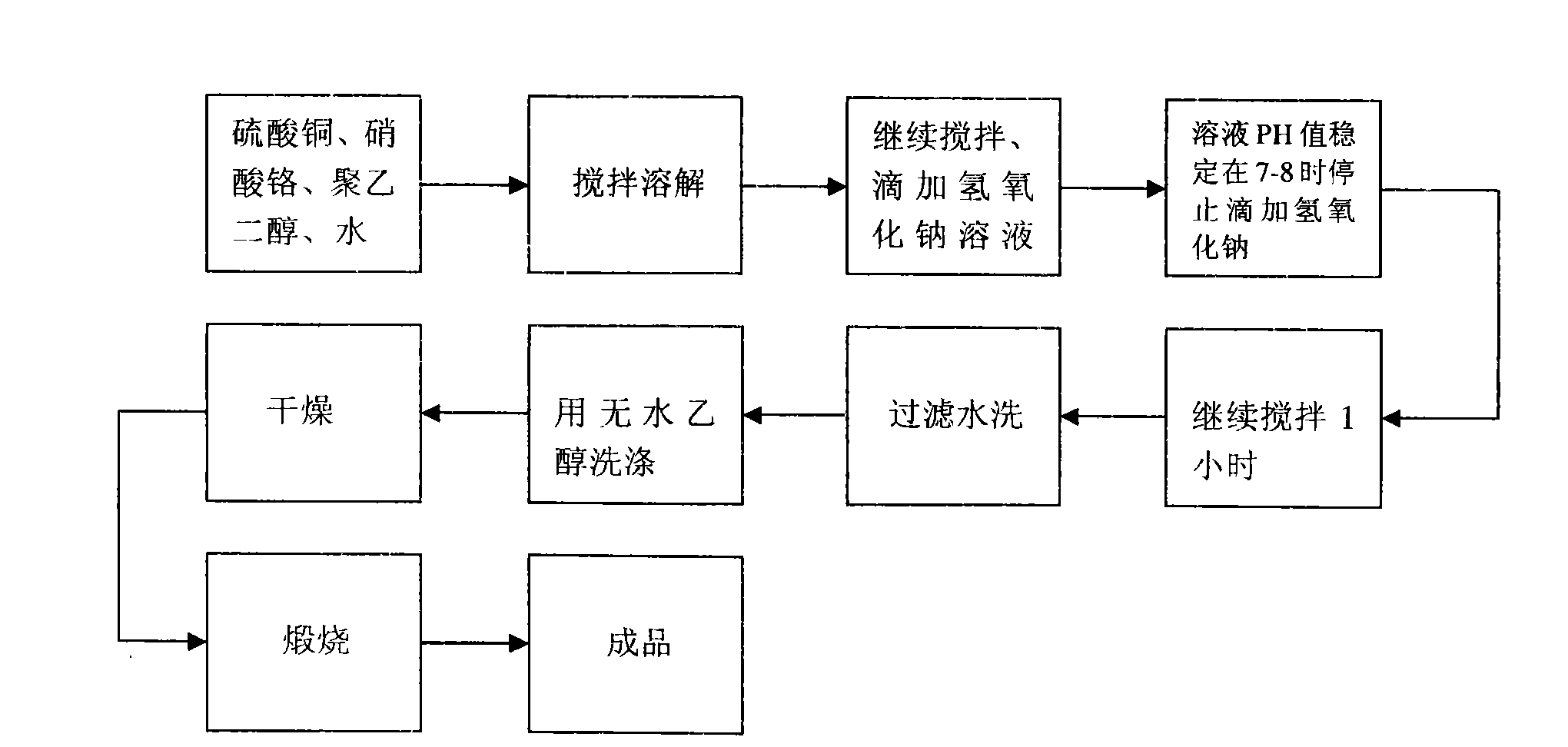

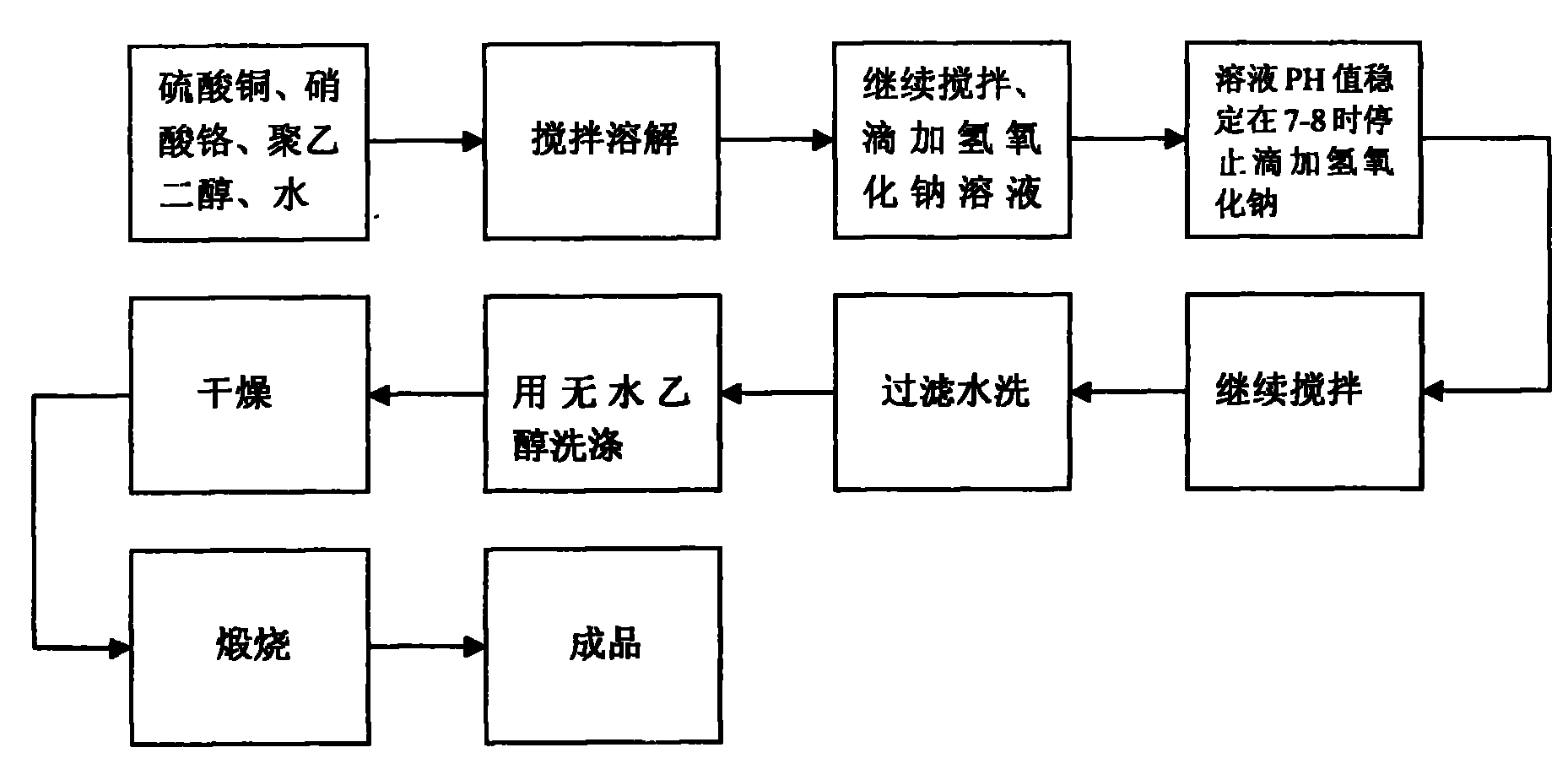

The invention relates to an inorganic synthesis method for preparing a copper and chromium black pigment. The copper and chromium black pigment has the following raw material formula: 250 grams of bluevitriod, 340 to 460 grams of chromium nitrate nonahydrate, 27 to 37 grams of polyethylene glycol and 170 to 230 ml of absolute alcohol. Due to the adoption of the method, the problems of large particles and uncentralized particle diameter distribution of the copper and chromium black pigment produced by a conventional method are solved; the production steps are simplified; the calcining temperature is reduced; and compared with an organic pigment, the copper and chromium black pigment has good high temperature stability and wide application range.

Description

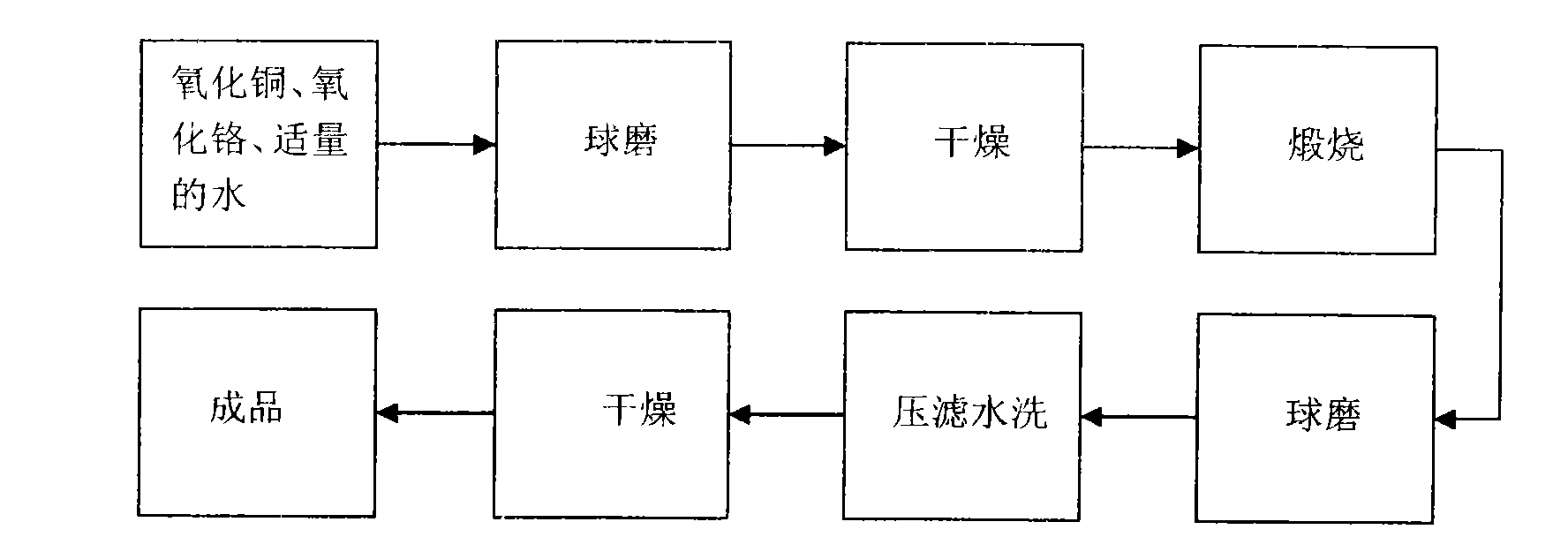

technical field [0001] The invention relates to a production method of copper chrome black pigment. Background technique [0002] The production method of copper chrome black pigment is well known. The main methods of producing copper chrome black pigments are traditional solid phase method and some old chemical methods. Traditional solid-phase process (see the specific process flow chart figure 1 ) mainly utilizes copper oxide and chromium oxide through ball mill mixing, drying, calcining, semi-finished product ball milling, washing, drying, and finished product. The pigments synthesized by this method are limited by the particle size of various raw materials and the performance of the ball mill. Even after a long time of ball milling, the pigments cannot be fully mixed. The contact area between the reactants is small and the reactivity is low, which makes the synthesis temperature high. Generally, it needs to be at 1200 degrees Celsius. Above, after calcination, the pig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09C1/34C09C3/10C08K3/22C09D7/12

Inventor 刘嵋苓

Owner 邵阳县彩鑫制釉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com