Solvent-free epoxy coating

An epoxy coating, solvent-free technology, applied in the field of coatings, can solve the problems of paint film flatness, adhesion and flexibility that cannot meet the requirements, achieve high hardness, strong adhesion, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A solvent-free epoxy coating, characterized in that: it is obtained by grinding and stirring 50 parts of epoxy resin, 10 parts of toughening agent, 5 parts of pigment, 15 parts of filler and 2 parts of auxiliary agent, in parts by weight;

[0028] The epoxy resin is bisphenol A type epoxy resin; the toughening agent is polysulfide rubber; the pigment is iron red; the filler is talcum powder; the auxiliary agent is an organic silicone defoamer, Organic silicone leveling agent, dispersant, coupling agent, polymerization inhibitor and abrasive agent.

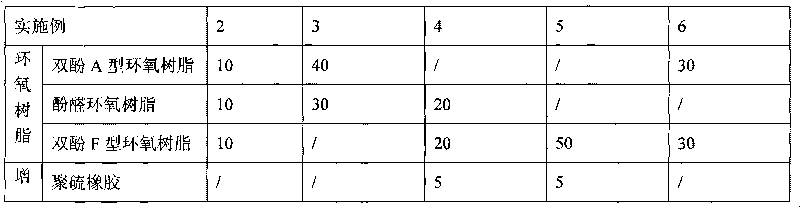

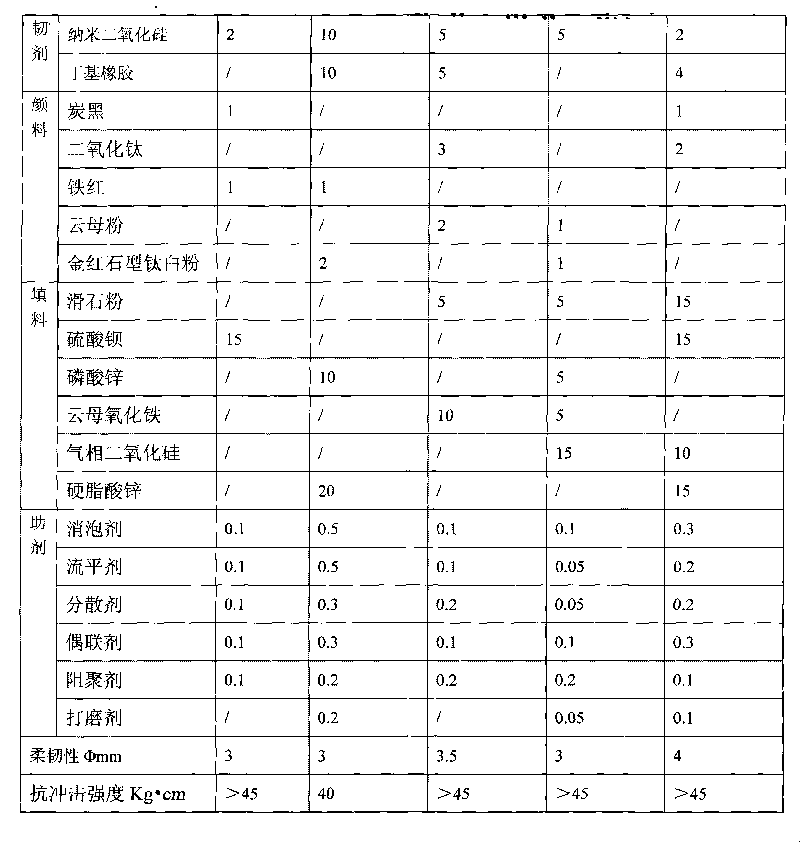

Embodiment 2~6

[0030] A solvent-free epoxy coating, its components, content and performance parameters are shown in Table 3, and the others are the same as in Example 1.

[0031] Each component, content and performance parameter in table 3 embodiment 2~6, content is by weight

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com