Single-component cationoid water-soluble epoxy-polyurethane anticorrosion primer system drying at 150 DEG C

A cationic, water-based epoxy technology, used in polyurea/polyurethane coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as serious water resistance and achieve excellent construction performance, good overall performance, and good elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

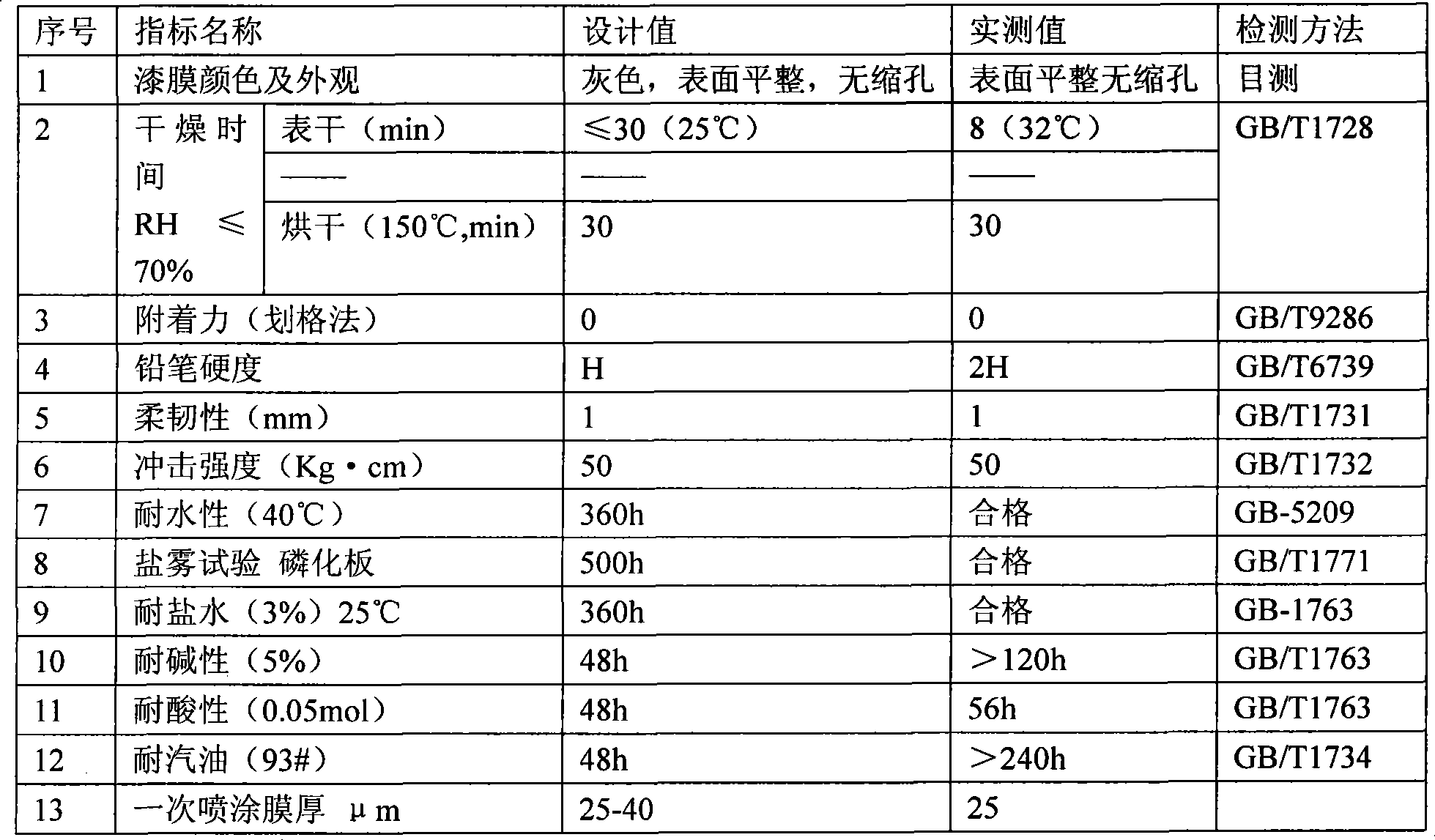

Image

Examples

preparation example Construction

[0024] The preparation method of above-mentioned aqueous cationic epoxy resin is characterized in that it comprises the following steps:

[0025] (1) Preparation of modified epoxy resin: Put 20-35 parts of epoxy resin, 10-30 parts of alcohol ethers and ketone solvents into the reaction kettle, stir and dissolve at 50°C-80°C for 1 hour, then add 0.5% fatty amine -2 parts were reacted at 80°C-90°C for 2-3 hours; after the reaction was completed, 10-25 parts of ketimine resin was added dropwise at 75°C-90°C into the reactor and kept warm for 1.5-2.5 hours to obtain modified epoxy resin;

[0026] (2) Preparation of curing agent: Put 5-20 parts of aromatic polyisocyanate into the reaction pot, add or drop 3-30 parts of alcohol ether monohydroxyl compound or heterocyclic hydroxyl-containing compound in batches at 20-50°C, 0-80 parts of polyether or polycarbonate diol (if the polycarbonate diol or polyether needs to be dissolved in a solvent in advance); then keep warm at 40-60°C fo...

Embodiment 1

[0029] Put 76 parts of TDI into the reaction pot, start stirring and add 46 parts of tetrahydrofurfuryl alcohol in batches below 50°C, keep warm at 50°C for half an hour, then raise the temperature to 80°C and keep warm for 2 hours to obtain a semi-closed polyurethane curing agent.

Embodiment 2

[0031] Put 33.4 parts of acetylacetone, 55.3 parts of TDI, 1 part of dimethylethanolamine, and 80 parts of solvent butanone into the reaction pot, heat and stir, heat at 70°C for 30 minutes, then raise the temperature to 85°C and react for 4 hours to obtain the closed type Polyurethane curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com