Flexible epoxy intumescence fire-retardant coating and preparation method thereof

A fire-resistant coating and flexible epoxy technology, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve problems such as large internal stress, separation, and easy cracking of fire-resistant coatings, and achieve excellent water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

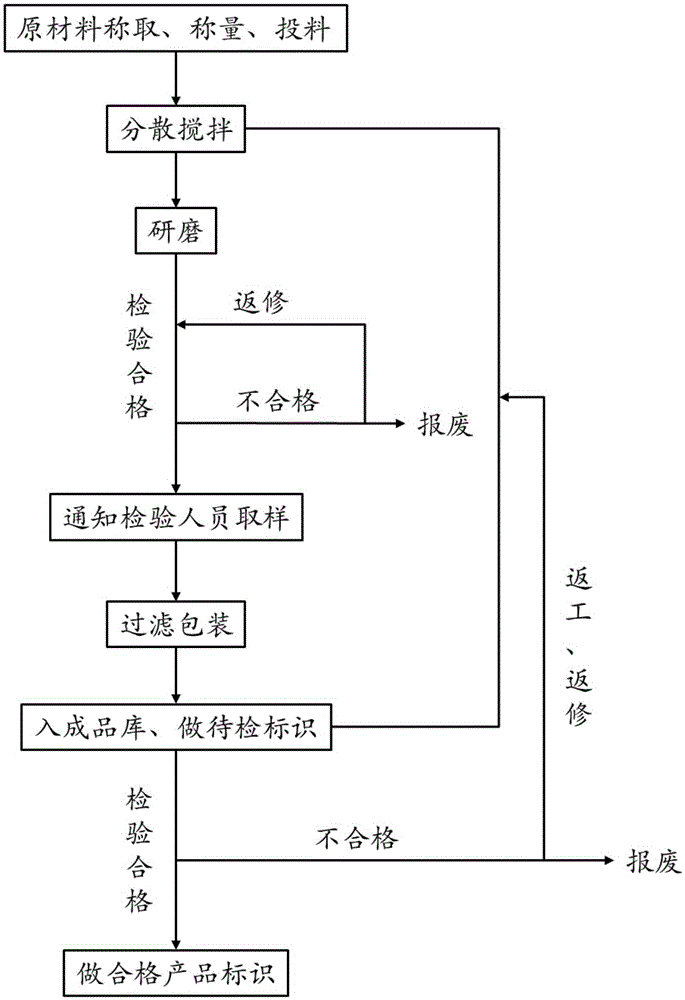

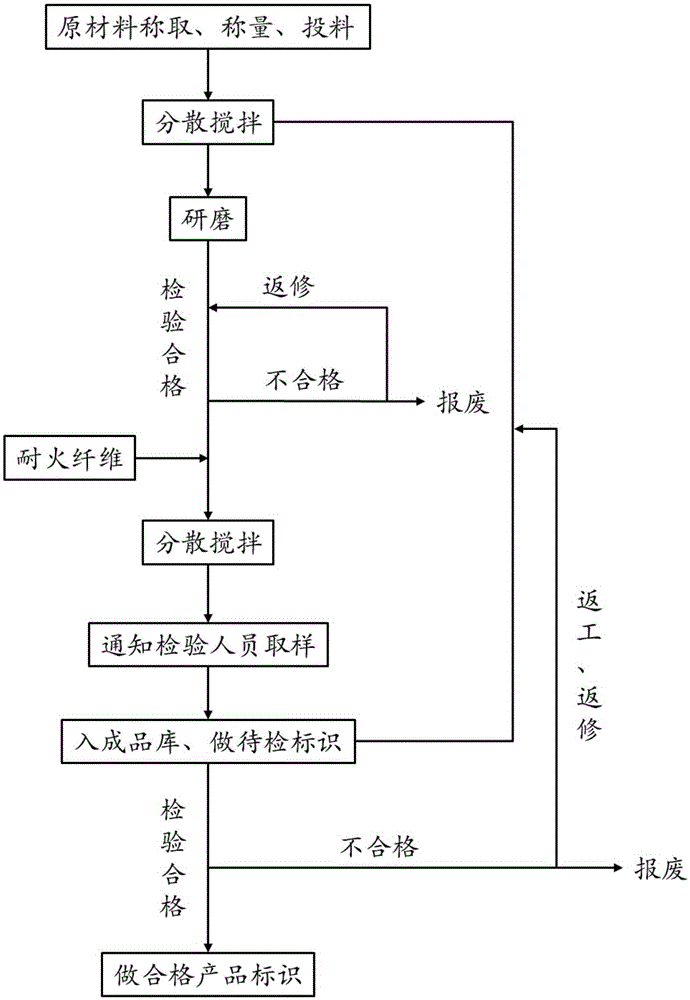

Method used

Image

Examples

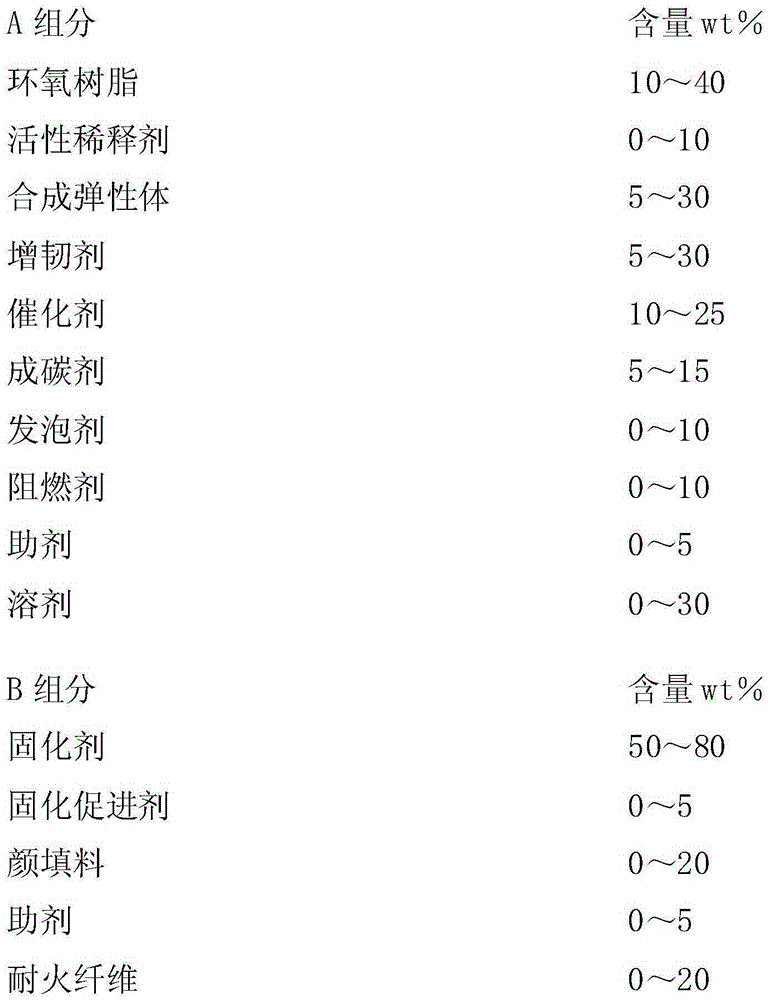

Embodiment 1

[0028]

[0029] A and B are used in a ratio of 2:1.

[0030] The performance of the test paint film is as follows.

[0031]

[0032] The impact of different additions of tougheners and synthetic elastomers on the parameters of the intumescent carbon layer of fire retardant coatings and the impact on fire performance are compared in the table below. The test conditions are that the flame temperature is 2000 ° F, the coating thickness is 1 mm, and the fire test time is 15 minutes. Except for the toughening agent and the synthetic elastomer, the dosage ratio of each raw material is consistent with that of Example 1.

[0033] Table 1 Parameters of intumescent carbon layer of fire retardant coatings and comparison of fire performance

[0034]

Embodiment 2

[0036]

[0037] A and B are used in a ratio of 6:1.

[0038] The performance of the test paint film is as follows.

[0039]

[0040]

Embodiment 3

[0042]

[0043] A and B components are used in a ratio of 3:1.

[0044] The performance of the test paint film is as follows.

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com