Aqueous high-performance monocomponent primer-topcoat anti-corrosion coating

A high-performance technology for anti-corrosion coatings, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor weather resistance and salt spray resistance, and achieve the effects of low VOC content, fast drying, and excellent salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

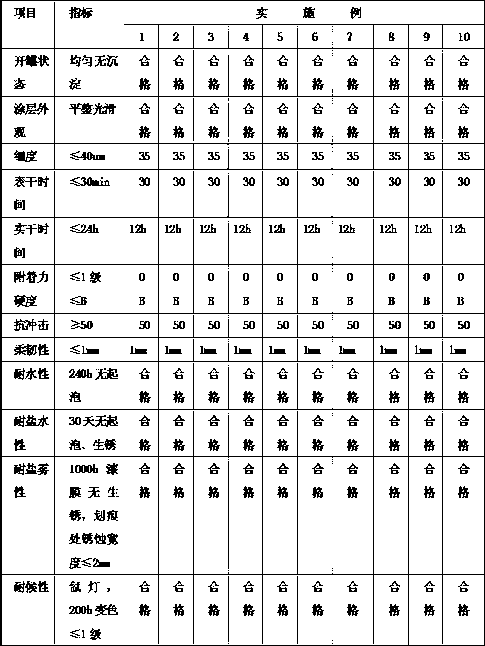

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned water-based high-performance single-component bottom-surface-integrated anticorrosion coating comprises the following steps:

[0036] 1) Mix demineralized water, film-forming additives, anti-flash rust agents, thickening and anti-settling agents, and auxiliary additives, and stir for 5-10 minutes at a speed of 400-600 rpm to obtain mixture 1;

[0037] 2) Add coloring pigments, anti-rust pigments and fillers to mixture 1, stir for 20-30 min, and rotate at 800-1200 rpm to obtain mixture 2;

[0038] 3) Grind the mixture 2 with a sand mill, ball mill or three-roller until the fineness is less than 40 μm, then add water-based modified acrylic emulsion, stir for 10 minutes at a speed of 600-800 rpm, and use a 100-mesh copper mesh or nylon mesh Filter to get the finished product.

Embodiment 1

[0042] A water-based high-performance single-component bottom-surface-in-one anti-corrosion coating, which contains the following components in parts by weight: 40 parts of water-based modified acrylic emulsion (Dow HG-54C emulsion), 15 parts of titanium dioxide, 3 parts of iron oxide black, phosphoric acid 5 parts of zinc, 10 parts of precipitated barium sulfate, 5 parts of 1250 mesh talc powder, 1 part of ethylene glycol monobutyl ether, 2 parts of Texanol alcohol ester, 0.2 part of thickening and anti-sedimentation agent (Bentone LT), 16.5 parts of demineralized water (distilled water) 0.5 part of anti-flash rust agent (Raybo 60), 0.5 part of wetting agent, 0.3 part of defoamer, 0.5 part of dispersant, 0.1 part of antifungal agent, 0.1 part of preservative, 0.3 part of 25% ammonia water.

Embodiment 2

[0044] A water-based high-performance single-component bottom-surface-in-one anti-corrosion coating, which contains the following components by weight: 50 parts of water-based modified acrylic emulsion (Dow HG-54C emulsion), 15 parts of iron oxide red, and 5 parts of aluminum tripolyphosphate , 8 parts of precipitated barium sulfate, 1 part of ethylene glycol monobutyl ether, 2 parts of Texanol alcohol ester, 0.2 parts of thickening and anti-settling agent (Bentone LT), 16.5 parts of demineralized water (distilled water), 0.5 parts of anti-flash rust agent (FA179) 0.5 part of wetting agent, 0.3 part of defoamer, 0.5 part of dispersant, 0.1 part of antifungal agent, 0.1 part of preservative, and 0.3 part of diethanolamine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salt spray resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com