Fish collagen composite fibers and preparation method thereof

A fish collagen and composite fiber technology, applied in the preparation of spinning solution, cellulose/protein conjugated rayon, chemical post-treatment of cellulose/protein rayon, etc., to avoid poor moisture absorption performance and dyeing performance, wear Comfortable and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

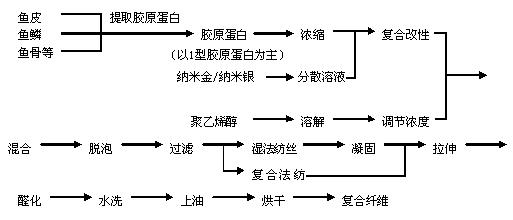

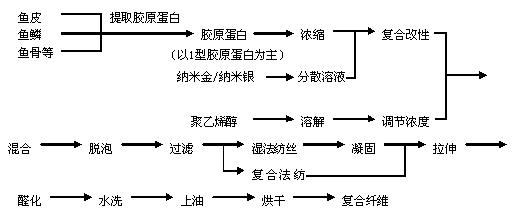

Method used

Image

Examples

Embodiment 1

[0054] 1. Decalcification: Soak 1 kg of frozen fish skin in tap water at 4°C and rinse until there is no other solid matter outside the whole fish skin in the soaking solution, then soak and rinse with deionized water for 5 times. Fish skin was soaked in 6% (W / V) NaCl solution for 1 day to remove non-collagen, and then soaked in disodium ethylenediaminetetraacetic acid (EDTA) solution for decalcification.

[0055] 2. Extraction of acid-soluble collagen (ASC): add decalcified fish skin to 0.5mol / L HAc and 0.1mol / L HC1 solution respectively, soak for 2 days, centrifuge (10 000×g, 30 min), and take the supernatant The liquid was repeatedly centrifuged once, and the supernatants were combined to obtain a crude ASC extract.

[0056] 3. Enzymatic acid-soluble collagen (PSC) extraction: put the residue obtained in step 2 into 0.5mol / L HAC and 0.1mol / L HC1 solutions containing 1% (W / V) pepsin, stir and digest On 2 days, centrifuge (10 000 × g, 30 min), take the supernatant, repeat th...

Embodiment 2

[0064] 1. Decalcification: Clean fish scales, fish cartilage, etc., soak and rinse 1 kg of frozen fish scales and fish cartilage with 4°C tap water until there are no other solids in the soaking solution, then soak and rinse with deionized water for 5 times . Soak fish scales and cartilage in 6% (W / V) NaCl solution for 1 day to remove non-collagen, and then soak in disodium ethylenediaminetetraacetic acid (EDTA) solution for decalcification.

[0065] 2. Extraction of acid-soluble collagen (ASC): Add 0.5mol / L HAc and 0.1mol / L HC1 solution to decalcified fish scales and fish cartilage at a ratio of 5:3, soak for 2 days, centrifuge (10 000×g, 30 rain), the supernatant was taken and centrifuged repeatedly once, and the supernatant was combined to obtain the crude ASC extract.

[0066] 3. Enzymatic acid-soluble collagen (PSC) extraction: put the residue obtained in step 2 into 0.5mol / L HAC and 0.1mol / L HC1 solutions containing 1% (W / V) pepsin, stir and digest 2 days, centrifuge (...

Embodiment 3

[0074] 1. Decalcification: Clean fish skin, fish scales, fish cartilage, etc., soak 1 kg of frozen fish skin, fish scales, and fish cartilage in tap water at 4°C until there is no other solid matter in the soaking solution, and then use it Soak in deionized water and rinse 5 times. Soak fish scales and cartilage in 6% (W / V) NaCl solution for 1 day to remove non-collagen, and then soak in disodium ethylenediaminetetraacetic acid (EDTA) solution for decalcification.

[0075] 2. Extraction of acid-soluble collagen (ASC): Add 0.5mol / L HAc and 0.1mol / L HC1 solution to decalcified fish scales and fish cartilage at a ratio of 5:3, soak for 2 days, centrifuge (10 000×g, 30 rain), the supernatant was taken and centrifuged repeatedly once, and the supernatant was combined to obtain the crude ASC extract.

[0076]3. Enzymatic acid-soluble collagen (PSC) extraction: put the residue obtained in step 2 into 0.5mol / L HAC and 0.1mol / L HC1 solutions containing 1% (W / V) pepsin, stir and digest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com