NiCoCrAlY / ZrO2 composite coating on gamma-TiAl alloy surface and preparation method thereof

A composite coating and alloy technology, applied in metal material coating process, coating, superimposed layer plating and other directions, can solve the problems of high temperature oxidation resistance, poor tribological performance and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

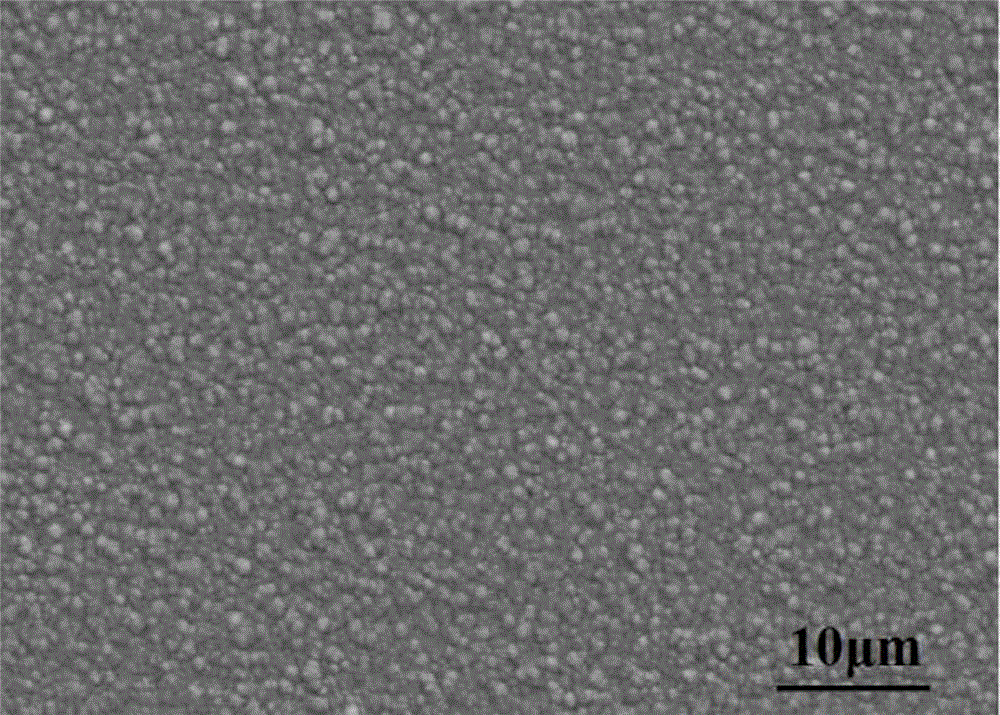

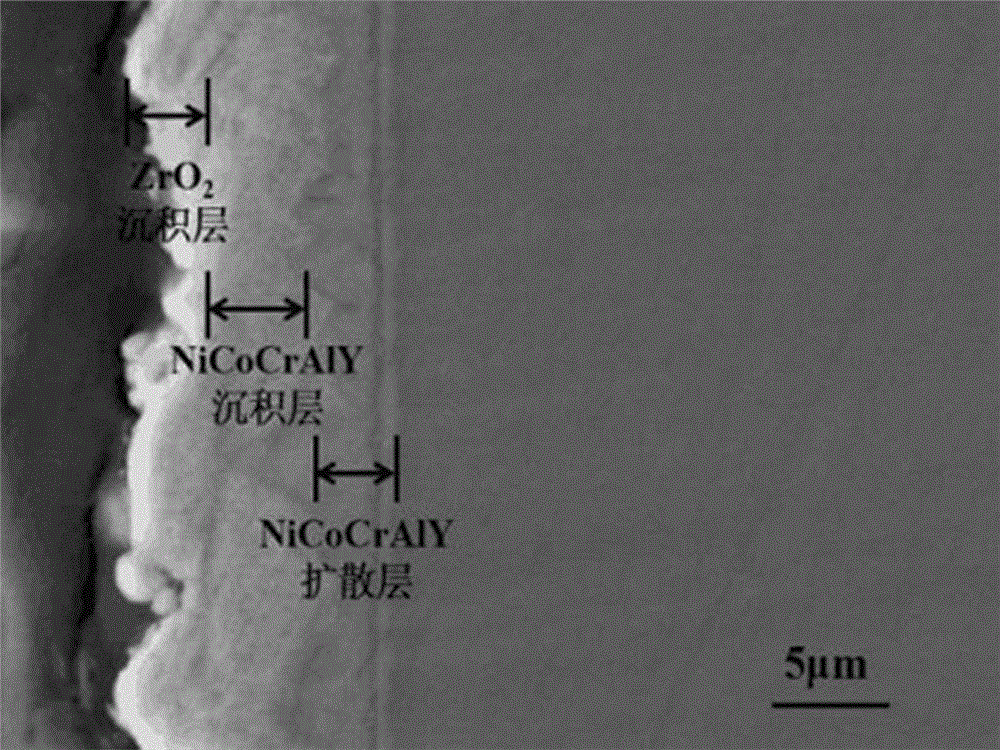

Method used

Image

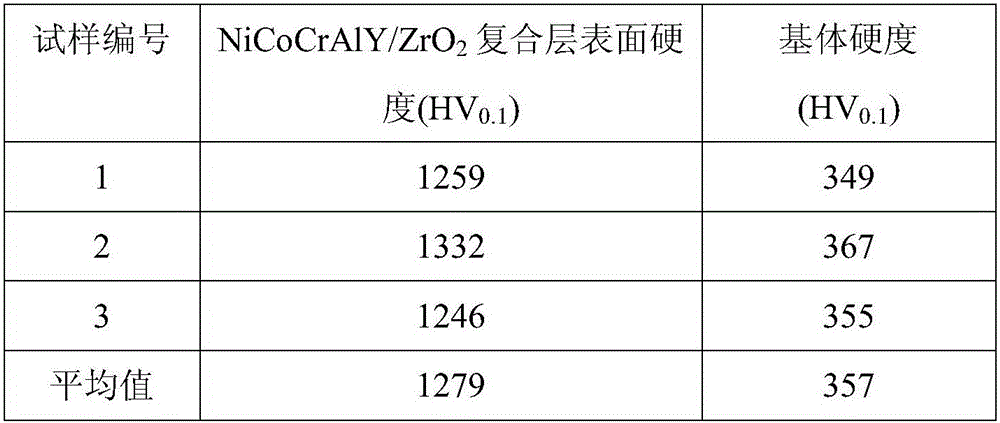

Examples

Embodiment 1

[0037] (1) After cutting the γ-TiAl alloy into a sample of 15×15×5 mm, the surface of the sample was first polished with sandpaper, and then Cr 2 o 3 The polishing powder is polished to a mirror surface, and finally placed in alcohol for ultrasonic cleaning;

[0038] (2) Place NiCoCrAlY (composition Ni-(20~23)Co-(20~24)Cr-(11~13)Al-(0.25~0.45)Y) at the source of the double-layer glow plasma metallization furnace and pure Zr (purity 99.99%) targets, the size is Before loading into the furnace, the target material needs to be polished with sandpaper to expose the fresh surface, ultrasonically cleaned with anhydrous ethanol, and dried;

[0039](3) The γ-TiAl alloy sample is placed on the stage, parallel to the target, the distance between the NiCoCrAlY alloy target and the γ-TiAl alloy sample is controlled at 15-20mm, and then the bell jar is lowered;

[0040] (4) Turn on the mechanical pump to evacuate to below 5pa, pass in argon, adjust the air pressure in the furnace to 35...

Embodiment 2

[0061] Except that the parameters of Zr-O co-infiltration are changed to working pressure of 45Pa, source voltage of 950V, cathode voltage of 450V, pole spacing of 15mm, argon and oxygen flow ratio of 10:1, and heat preservation for 2 hours, other steps are the same as in Example 1 .

[0062] In the room temperature friction and wear test of this embodiment, the friction coefficient of the coating is 0.28, and the wear amount is 0.57mg, which is 77.01% lower than that of the substrate. The high temperature oxidation tests at 750°C, 850°C, and 950°C show that the coating After 100h, it is well bonded to the substrate, the surface does not peel off, and the oxidation weight gain is 25mg / cm 2 , is further reduced than in Example 1, and the oxidation resistance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com