Slender metal pipe inner wall diamond-film-like deposition method using DC glow discharge

A DC glow discharge, diamond-like film technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of complex equipment and high cost, and achieve low equipment cost, convenient use and maintenance. , the effect of easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

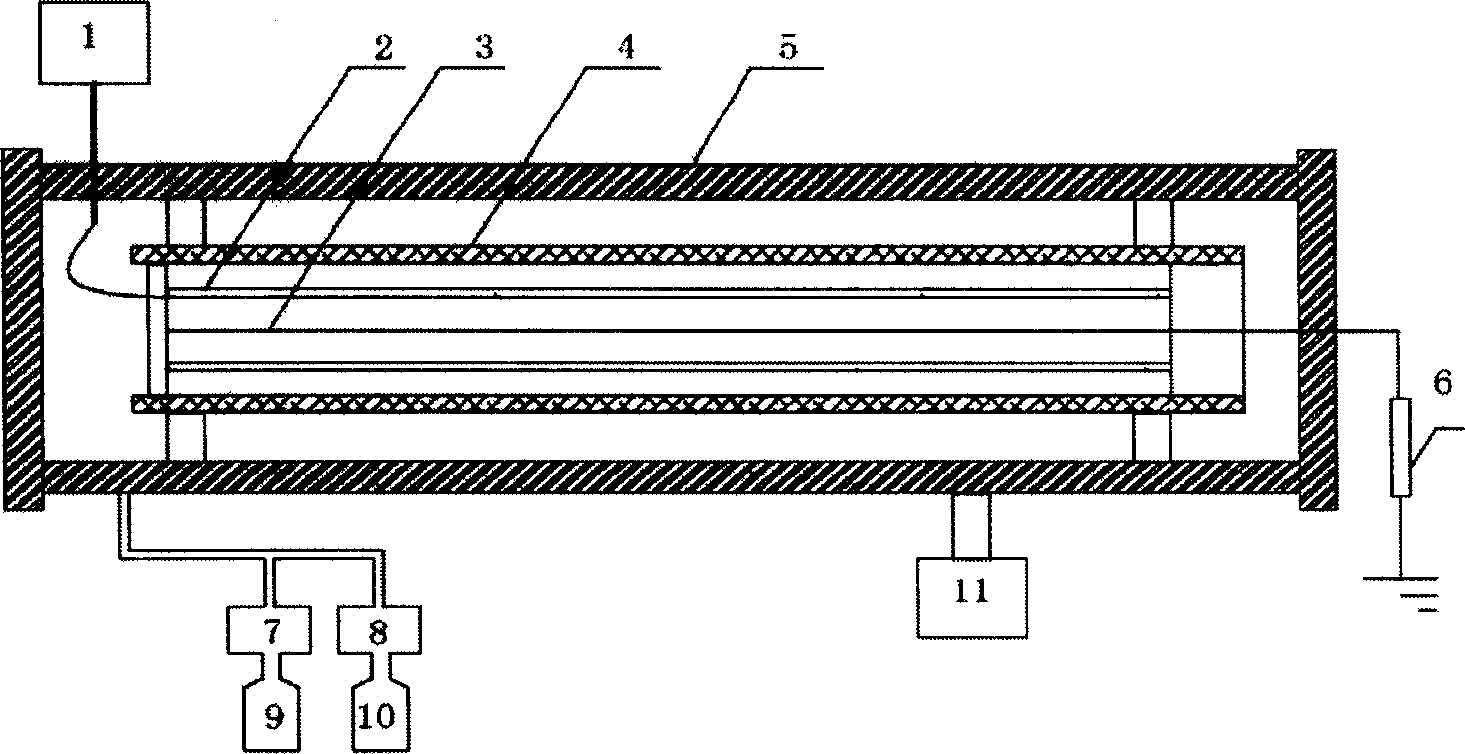

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0012] Pull a tungsten wire with a diameter of 30 to 200 microns on the axis of the slender metal tube to be treated to form a coaxial electrode structure, and coat an insulating ceramic tube on the thin tube (the specific size depends on the size of the slender metal tube to be modified) ). Make a vacuum chamber with a stainless steel tube with a diameter of about 10cm (the specific length and diameter of the vacuum chamber are selected according to the size of the slender metal tube to be modified), put the slender metal tube to be treated with the insulating ceramic tube into the vacuum in the room. Pump the vacuum chamber to 10 with a mechanical pump (pumping speed > 4 liters / second) -1 Below Pa, then input the mixed gas of argon and methane or acetylene into the vacuum chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com