One-step method for preparing high-density WRe/TZM gradient composite material

A composite material and dense technology, applied in X-ray tube parts, X-ray tube electrodes, etc., can solve the problems of high cost, complicated process, and difficulty in meeting the density requirements, and achieve high bonding strength and hardness, and process Simple, short sintering time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment manufactures the WRe / TZM gradient composite material for the X-ray tube of a CT machine as follows:

[0034] (1) Take WRe alloy powder and TZM alloy powder as raw materials as required;

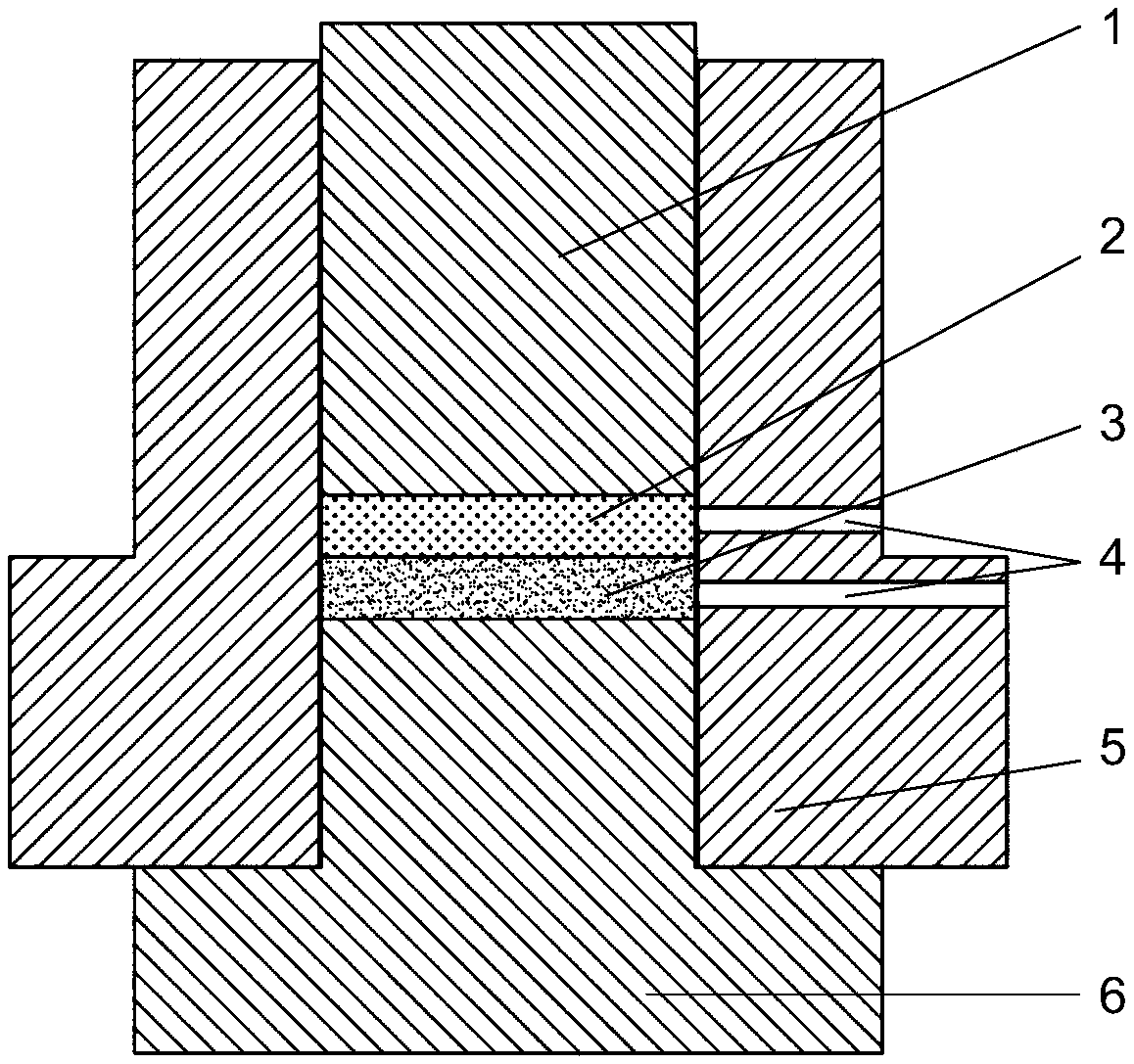

[0035](2) First install the lower pressure head on the concave die of the gradient mold, then load TZM alloy powder, and use a manual hydraulic press to pre-press with a pressure of 10 MPa. After holding the pressure for 2 minutes, load WRe alloy powder, and also use 10 MPa for pre-pressing. , and finally put it into the upper indenter; add a layer of 0.2mm thick graphite paper between the sample and the mold and the indenter to prevent the sample from reacting with graphite and facilitate demoulding;

[0036] (3) Wrap a layer of 5mm thick carbon felt on the gradient mold after the raw materials are installed, and then put it into the SPS furnace cavity for sintering connection to obtain the WRe / TZM gradient composite material;

[0037] The sintering connection ...

Embodiment 2

[0041] The present embodiment manufactures the WRe / TZM gradient composite material for the X-ray tube of a CT machine as follows:

[0042] (1) Take WRe alloy powder and TZM alloy powder as raw materials as required;

[0043] (2) First install the lower pressure head on the concave die of the gradient mold, then load TZM alloy powder, and use a manual hydraulic press to pre-press with a pressure of 10 MPa. After holding the pressure for 2 minutes, load WRe alloy powder, and also use 10 MPa for pre-pressing. , and finally put it into the upper indenter; add a layer of 0.2mm thick graphite paper between the sample and the mold and the indenter to prevent the sample from reacting with graphite and facilitate demoulding;

[0044] (3) Wrap a layer of 5mm thick carbon felt on the gradient mold after the raw materials are installed, and then put it into the SPS furnace cavity for sintering connection to obtain the WRe / TZM gradient composite material;

[0045] The process of sintering...

Embodiment 3

[0049] The present embodiment manufactures the WRe / TZM gradient composite material for the X-ray tube of a CT machine as follows:

[0050] (1) Take WRe alloy powder and TZM alloy powder as raw materials as required;

[0051] (2) First install the lower pressure head on the concave die of the gradient mold, then load TZM alloy powder, and use a manual hydraulic press to pre-press with a pressure of 10 MPa. After holding the pressure for 2 minutes, load WRe alloy powder, and also use 10 MPa for pre-pressing. , and finally put it into the upper indenter; add a layer of 0.2mm thick graphite paper between the sample and the mold and the indenter to prevent the sample from reacting with graphite and facilitate demoulding;

[0052] (3) Wrap a layer of 5mm thick carbon felt on the outside of the gradient mold after pre-pressing, and then put it into the SPS furnace cavity for sintering connection to obtain the WRe / TZM gradient composite material;

[0053] The process of sintering con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com