Vacuum heat-preserving plate for light building

A technology for vacuum insulation boards and buildings, which is applied in thermal insulation, building components, and climate change adaptation. The effect of easy purchase of materials and reduction of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

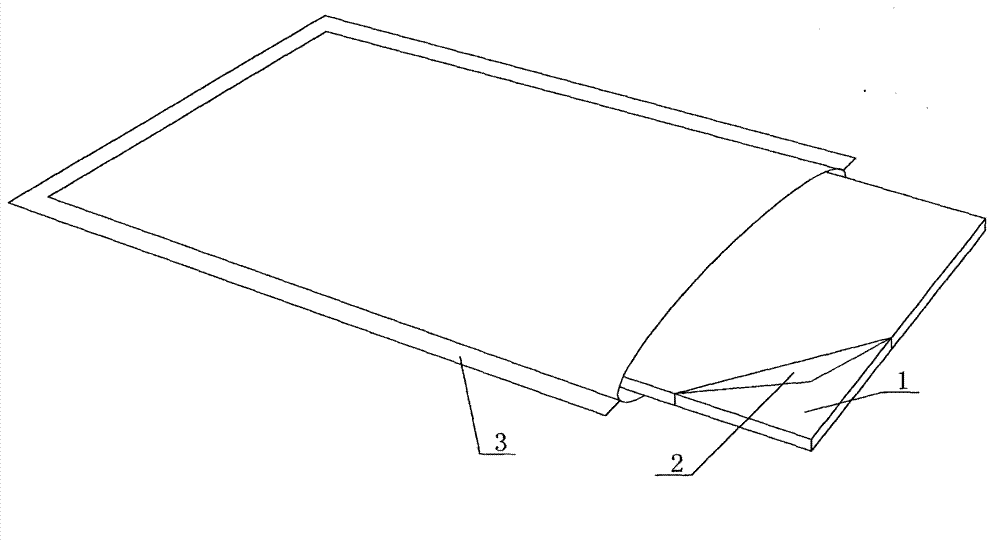

[0026] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the accompanying drawings, the structure of the present invention includes a low-density microporous inorganic thermal insulation layer 1, a core plate reinforced wrapping layer 2, and a low-permeability gas barrier film surface layer 3. The low-density microporous inorganic thermal insulation layer 1 and the core plate reinforced wrapping layer 2 and the surface layer 3 of the low-permeability gas barrier film form a vacuum insulation board.

[0027] The structure of the vacuum insulation board is, from inside to outside, a low-density microporous inorganic insulation layer 1, a core plate reinforced wrapping layer 2, and a low-permeability gas-barrier film surface layer 3, and the inside of the low-permeability gas-barrier film surface layer 3 is a vacuum .

[0028] The low-density microporous inorganic insulation layer 1 is composed of plant ash, silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com