Field enhancement metal insulator-semiconductor/metal insulator-metal electronic emitter

A technology of electron emitters and insulators, applied in circuits, electrical components, cold cathodes of discharge tubes, etc., can solve problems such as high stability and high reliability difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For simplicity and purpose of illustration, the principles of the invention are described primarily in terms of exemplary embodiments. However, those of ordinary skill in the art will appreciate that these principles are equally applicable to various types of electron emitters.

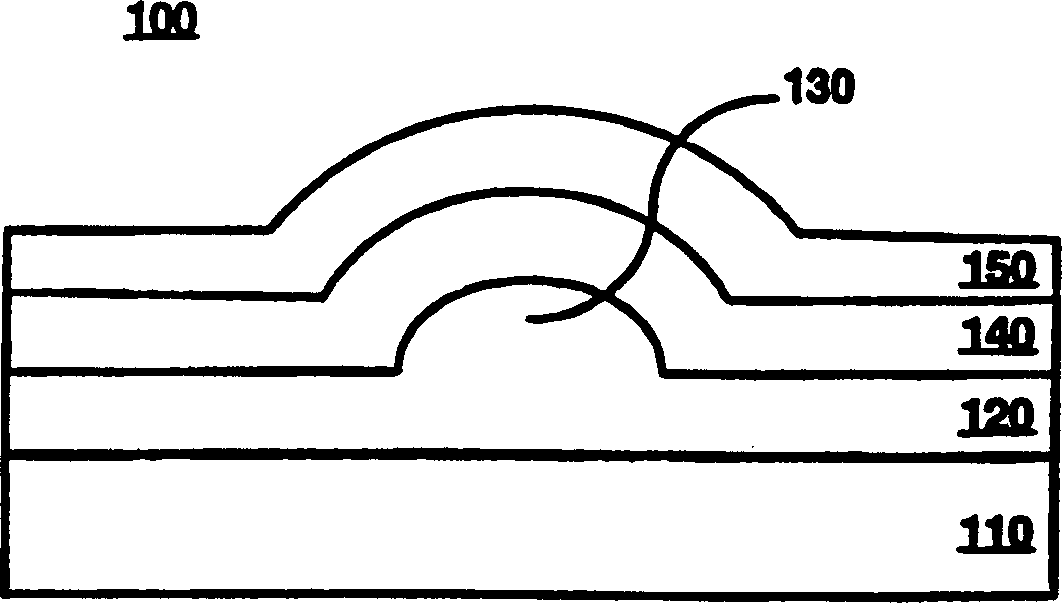

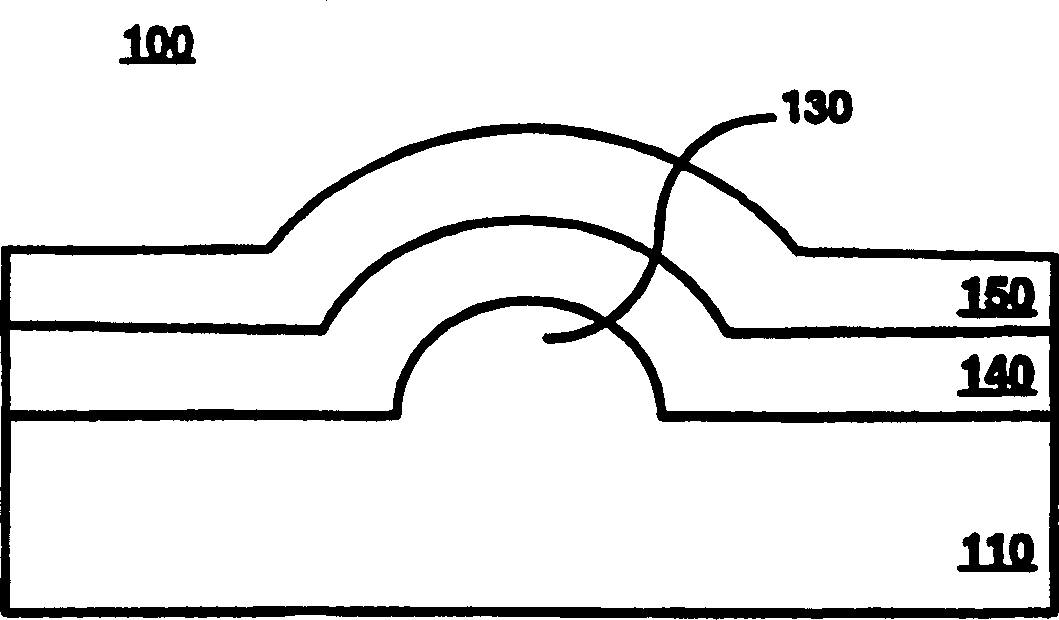

[0021] Figure 1A and 1B Cross-sectional views of first and second embodiments of an exemplary FEMIS electron emitter in an aspect of the invention are shown. As shown, the electron emitter 100 may include a conductive substrate 110 . The conductive substrate 110 can be made of metal (aluminum, tungsten, titanium, copper, gold, tantalum, platinum, iridium, palladium, cerbium, chromium, magnesium, scandium, yttrium, vanadium, pickaxe, niobium, molybdenum, silicon, beryllium, hafnium, silver, osmium and any alloy, and their multilayer films); doped polysilicon; doped silicon; graphite; metal coated glass, ceramics or plastics; indium tin oxide (ITO) coated glass, ceramics or plastics, etc. And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com