Method for treating industrial wastewater by low temperature using plasma and treating equipment

A low-temperature plasma and industrial wastewater technology, applied in water/sewage treatment, chemical instruments and methods, neutralization of water/sewage treatment, etc., can solve the problems of difficult control of microbial performance, low degradation rate of organic matter, large amount of coagulant, etc. , to achieve the effect of saving energy consumption, occupying a small area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

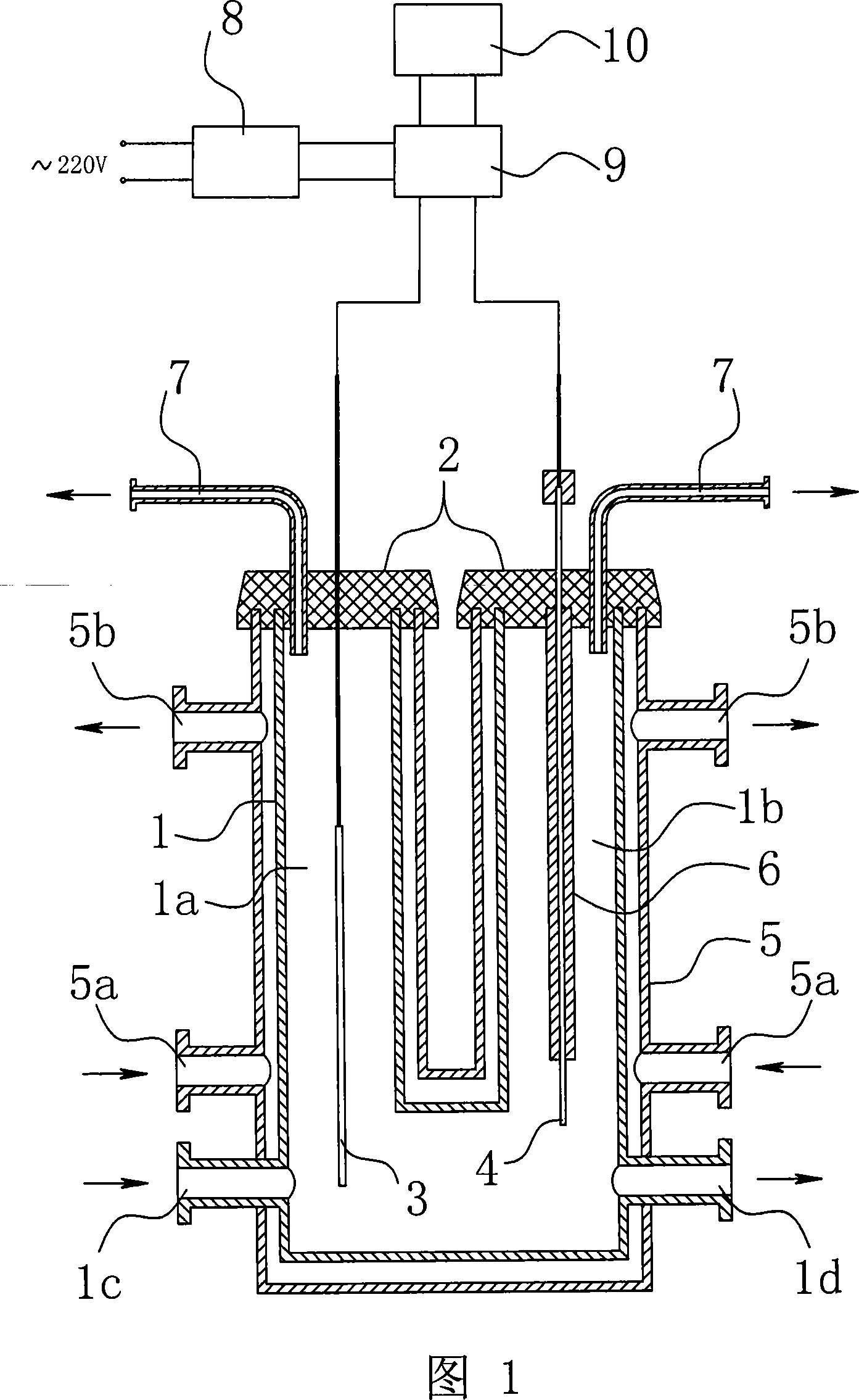

Image

Examples

Embodiment 1

[0023] Conditions: the distance between the centers of the cathode and anode electrodes is 5 cm, and the area ratio of the cathode electrode to the anode electrode is: 1:20.

[0024] Wastewater species: leather treatment and processing wastewater.

[0025] Treatment method: take 200ml of leather wastewater, adjust its conductivity to 15ms / cm with hydrochloric acid, pour it into a plasma reactor, and adjust the voltage at 150V to make the wastewater transition from conventional electrolysis to glow plasma electrolysis until the gas sheath around the cathode electrode The layer is broken down to form a glow plasma; adjust the voltage to 600V, at this time, under the action of the plasma, the wastewater boils violently, the substances in the wastewater are quickly decomposed, and the reaction time is 10 minutes; the treated wastewater is discharged and statically Set aside for 30min, at this time the solution was separated, and the supernatant was taken to measure its chromaticit...

Embodiment 2

[0031] Conditions: the distance between the centers of the cathode and anode electrodes is 4 cm, and the area ratio of the cathode electrode to the anode electrode is: 1:20.

[0032] Types of wastewater: printing and dyeing treatment and processing wastewater

[0033] Treatment method: Take 200ml of textile wastewater, adjust its conductivity to 20ms / cm with calcium hydroxide, pour it into a plasma reactor, and adjust the voltage at 100V to make the wastewater transition from conventional electrolysis to glow plasma electrolysis until the gas sheath around the cathode The layer is broken down to form a glow plasma; adjust the voltage to 600V, at this time, under the action of the plasma, the wastewater boils violently, the substances in the wastewater are quickly decomposed, and the reaction time is 10 minutes; the treated wastewater is discharged and statically Set aside for 30min, at this time the solution was separated, and the supernatant was taken to measure its chromatic...

Embodiment 3

[0039] Conditions: the distance between the centers of the cathode and anode electrodes is 4 cm, and the area ratio of the cathode electrode to the anode electrode is: 1:20.

[0040] Types of wastewater: Papermaking processing wastewater.

[0041] Take 200ml of papermaking wastewater, use sodium hydroxide to adjust its conductivity to 20ms / cm, pour it into a plasma reactor, and adjust the voltage at 100V to make the wastewater transition from conventional electrolysis to glow plasma electrolysis until the gas sheath around the cathode is Break down to form a glow plasma; adjust the voltage to 600V, at this time, under the action of the plasma, the wastewater boils violently, and the substances in the wastewater are quickly decomposed, and the reaction time is 10 minutes; discharge the treated wastewater and let it stand for 30 minutes At this time, the solution was separated, and the supernatant was taken to measure its chromaticity and COD value respectively.

[0042] The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com