Inkjet printing method

An inkjet printing and substrate technology, applied in printing and other directions, can solve the problems of dehydration and curling of blank parts, complicated process and raw materials, and high cost of UV ink method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

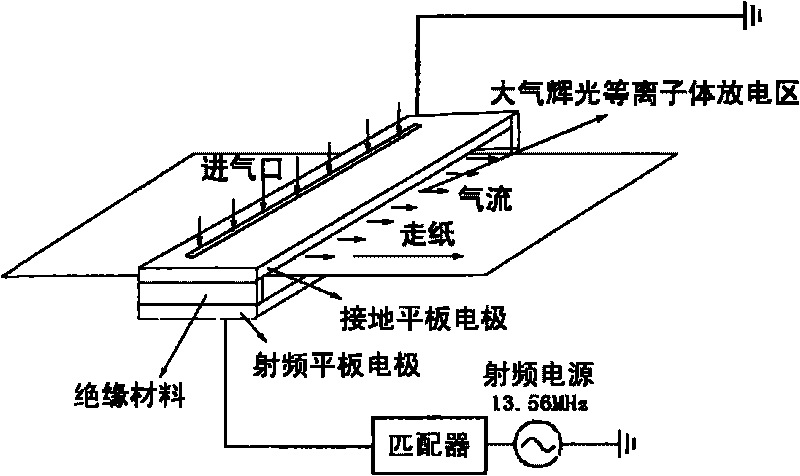

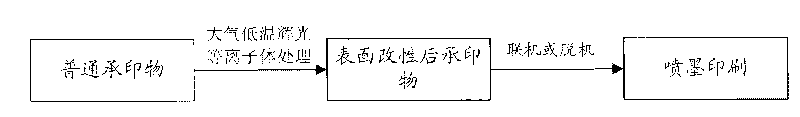

[0029] figure 1 A schematic diagram of an apparatus showing an inkjet printing method according to a preferred embodiment of the present invention. Such as figure 1 As shown, the upper and lower plate electrodes are placed in parallel, and the two ends are separated by insulating materials, and the working gas is introduced into the middle. Driven by the radio frequency power supply and the matching device, a uniform atmospheric glow plasma discharge is generated between the two plate electrodes, and after the plasma Surface modification occurs on the substrate surface of the module, and the treated substrate can be inkjet printed on-line or off-line.

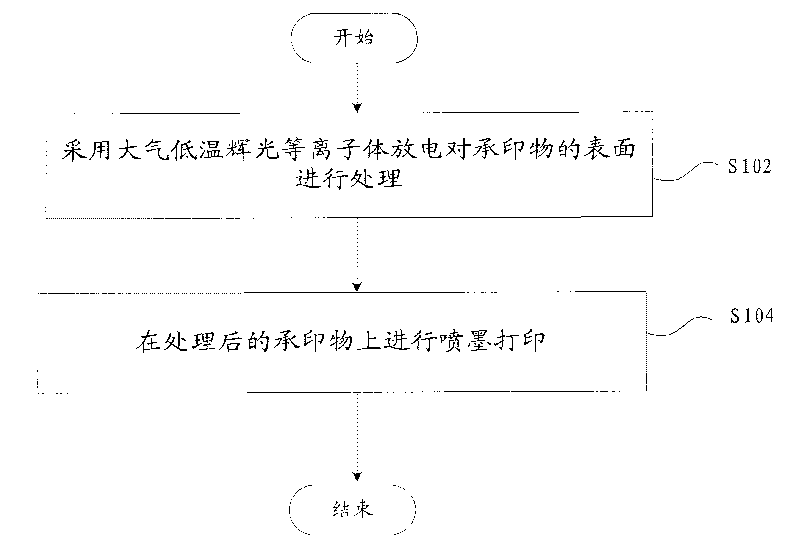

[0030] figure 2 A flow chart of an inkjet printing method according to an embodiment of the present invention is shown, including:

[0031] S102, treating the surface of the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com