Method for manufacturing gradient hard composite coating on surface of hard alloy

A composite coating, cemented carbide technology, applied in metal material coating process, coating, superimposed layer plating and other directions, can solve the complex process, long processing time and preparation process, not conducive to large-scale industrial production and other problems, to achieve the effect of shortening the process time, excellent bonding strength of the film base, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

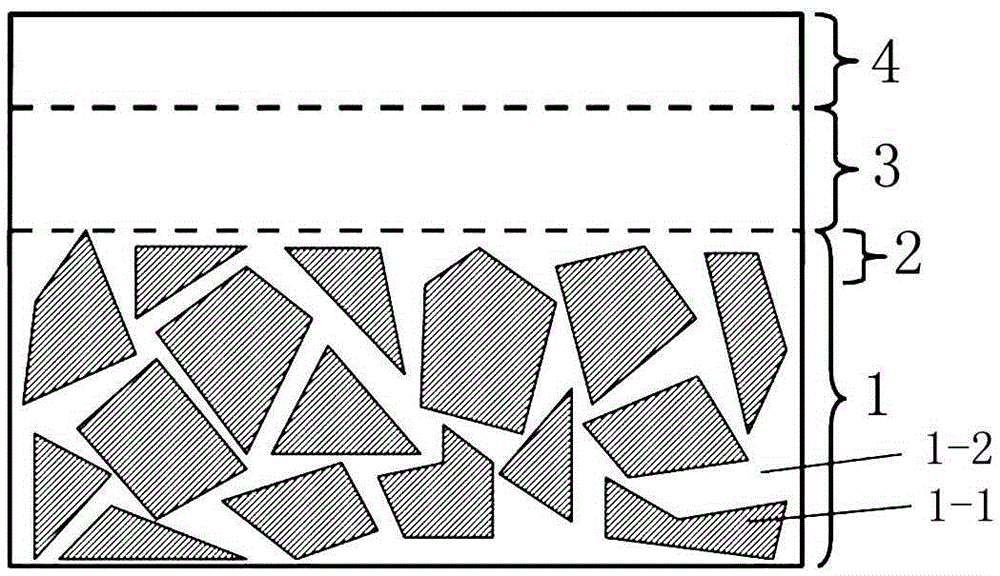

Image

Examples

Embodiment 1

[0021] Refractory Metal Titanium Ti

[0022] The method for preparing the gradient hard composite coating on the surface of the cemented carbide of the present invention specifically comprises the following steps:

[0023] 1) Prepare Ti and TiC composite infiltration layer on the surface of cemented carbide: ultrasonically clean the cemented carbide workpiece with deionized water and alcohol respectively, dry it with hot air, and place the cleaned cemented carbide workpiece in double-layer glow plasma On the substrate table of the body surface alloying equipment, a composite target made of Ti wire and graphite plate is used as the source, and the distance between the upper surface of the hard alloy workpiece and the target is controlled to be 18mm, and the double-layer glow plasma is When the surface alloying equipment is vacuumed below 1Pa, argon gas is introduced as the protective gas and plasma excitation gas, the flow rate is 70sccm, the internal pressure of the equipment ...

Embodiment 2

[0028] The refractory metal is tungsten W

[0029] The method for preparing the gradient hard composite coating on the surface of the cemented carbide of the present invention specifically comprises the following steps:

[0030] 1) Prepare W and W on the surface of cemented carbide x C (WC / W 2 C) Composite infiltration layer: Carbide workpieces are ultrasonically cleaned with deionized water and alcohol respectively, dried with hot air, and the cleaned carbide workpieces are placed on the substrate table of the double-layer glow plasma surface alloying equipment First, use the composite target made of W wire and graphite plate as the source, control the distance between the upper surface of the cemented carbide workpiece and the target to 20mm, and wait for the double-layer glow plasma surface alloying equipment to evacuate to below 1Pa At the same time, argon gas is introduced as the protective gas and plasma excitation gas, the flow rate is 80sccm, the internal pressure of...

Embodiment 3

[0034] The refractory metal is Hf

[0035] 1) Prepare Hf and HfC composite infiltration layer on the surface of cemented carbide: ultrasonically clean the cemented carbide workpiece with deionized water and alcohol respectively, dry it with hot air, and place the cleaned cemented carbide workpiece in double-layer glow plasma On the substrate stage of the body surface alloying equipment, a composite target made of Hf wire and graphite plate is used as the source, and the distance between the upper surface of the hard alloy workpiece and the target is controlled to be 19mm, and the double-layer glow plasma When the surface alloying equipment is evacuated below 1Pa, argon gas is introduced as the protective gas and plasma excitation gas. The temperature of the cemented carbide workpiece is raised to 850°C, and the treatment time is 20 minutes, and a Hf / HfC composite infiltrated layer with a depth of about 3 μm is formed on the surface of the cemented carbide;

[0036] 2) Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com