Platinum group metal alloy coating with controlled alloying elements and preparation method thereof

A technology of alloying elements and platinum group metals, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problems of low bonding strength of the coating, impurities in the coating, cracks in the coating, etc., to achieve Strong binding force, easy coating thickness, and the effect of coating thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

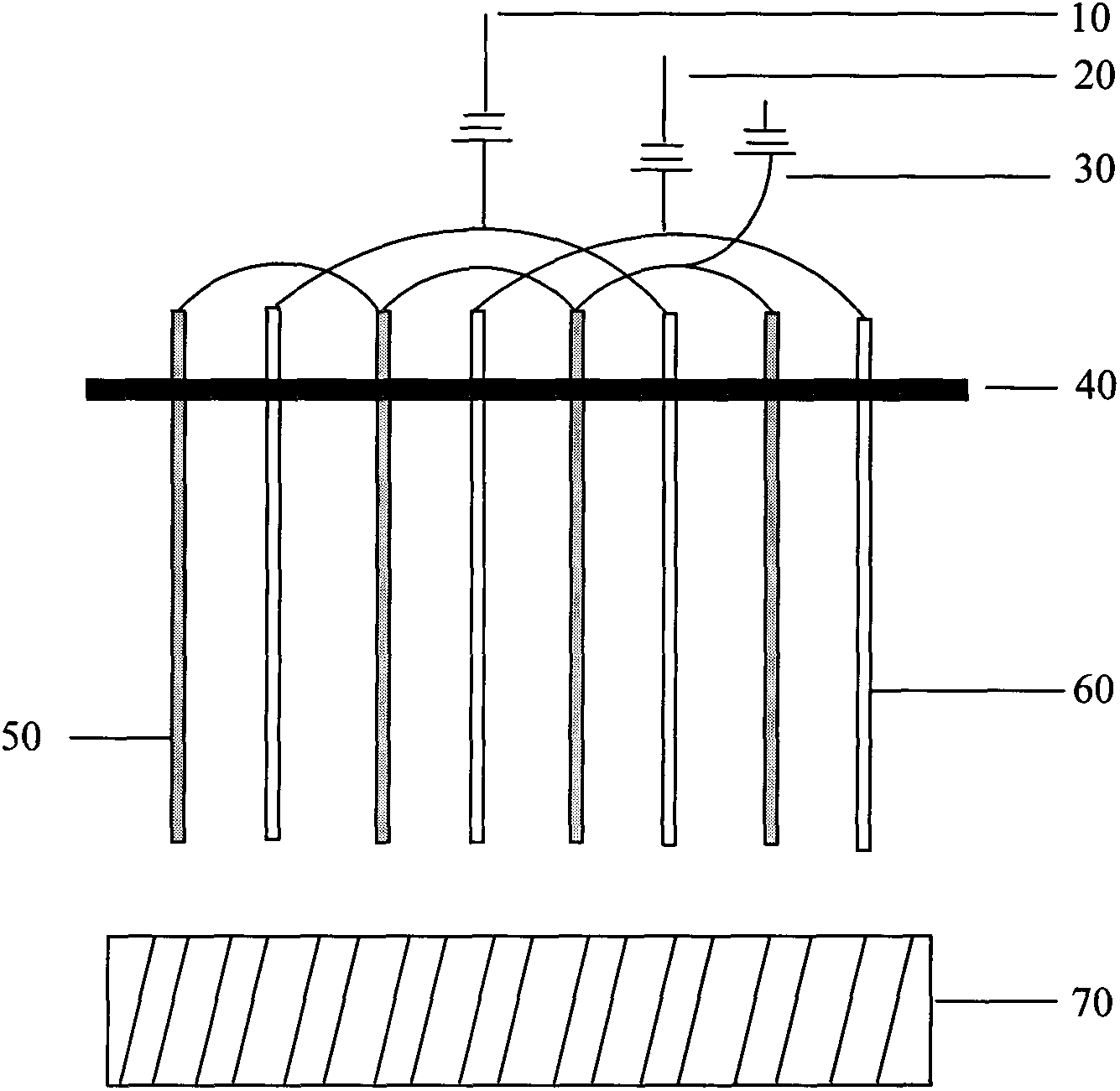

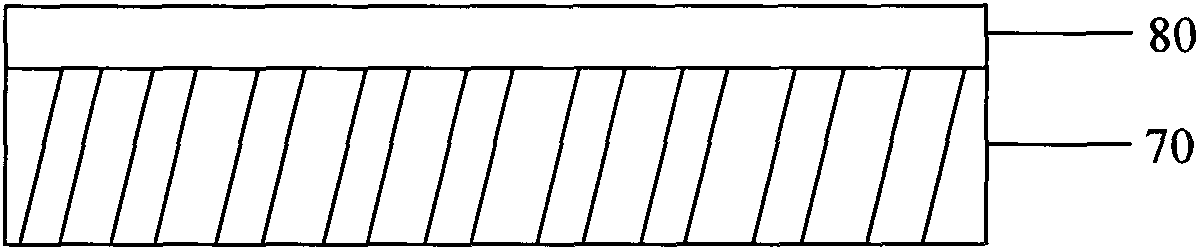

[0021] Select 12 iridium wires 50 and 12 zirconium wires 60 respectively, pass through the corundum disc 40, and adjust the lengths of the iridium wires 50 and zirconium wires 60 so that the end faces are flush and the distance from the molybdenum workpiece 70 is 17 mm. The six zirconium wires at the other end are connected to the power supply 10, the six zirconium wires are connected to the power supply 20, and the 12 iridium wires are connected to the power supply 30, and argon gas is introduced after vacuumizing to the ultimate vacuum. The process parameters of the dual-glow plasma technology are set as the target voltage is 900V, the substrate voltage is 350V, and the working pressure is 25Pa. Start deposition, after the workpiece is energized, turn on the iridium wire power supply 30, after 1 hour of deposition time, turn on the zirconium wire power supply 10, after another 1 hour of deposition, turn on the zirconium wire power supply 20, and after another 0.5 hour of depo...

Embodiment 2

[0023] 10 iridium wires 50, 3 zirconium wires and 3 hafnium wires 60 pass through the corundum disc 40, the distance between one end and the niobium workpiece 70 is 19 mm, the other end 3 zirconium wires are connected to the power source 10, and the 3 hafnium wires are connected to the power source 20 , 10 iridium wires are connected to the power supply 30, and argon gas is introduced after vacuuming to the ultimate vacuum. The process parameters of the dual-glow plasma technology are set to be 850V for the target, 320V for the substrate, and 25Pa for the working pressure. Start deposition. After the workpiece is powered on, turn on all source power supplies. After 1 hour of deposition time, turn off the zirconium wire power supply 10. After another 1 hour of deposition, turn off the hafnium wire power supply 20. After another 1 hour of deposition, turn off all power supplies. After deposition, an alloy coating with a thickness of 45 μm can be obtained. From the surface layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com