Method for preparing surface plasma nitrided layer of high-entropy alloy

A technology of high-entropy alloy and ion nitriding, which is applied in metal material coating process, coating, solid-state diffusion coating, etc., which can solve the problems of weak matrix bonding, easy falling off, workpiece deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

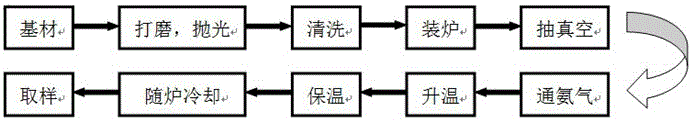

[0037] A kind of preparation high entropy alloy Al 1.3 CoCuFeNi 2 The method for surface ion nitriding layer, the concrete steps of this method are as follows:

[0038] Sample preparation

[0039] (1) Processing Al 1.3 CoCuFeNi 2 sample. The samples with the size of 10 mm × 10 mm × 1.5 mm were processed by wire cutting machine.

[0040] (2) Clean Al 1.3 CoCuFeNi 2 sample surface. The alloy samples were ground sequentially with 300#, 800#, 1000#, 1500# and 2500# SiC sandpapers of different particle sizes, and then mechanically polished with a diamond polishing paste with a particle size of 0.5 μm until there was no scratch on the surface under a 100× optical microscope. Finally, wash and dry with an ultrasonic cleaner in alcohol for later use.

[0041] Double glow plasma nitriding

[0042] (1) Furnace loading: Open the manual air release valve, fill the furnace with air, lift the furnace cylinder after the pressure inside and outside the furnace is consistent, and pla...

Embodiment 2

[0050] The difference from Example 1 is that AlCoCrFeNi is used as the base material for nitriding, and other steps are the same.

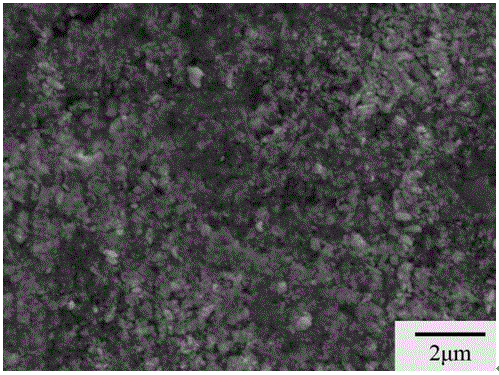

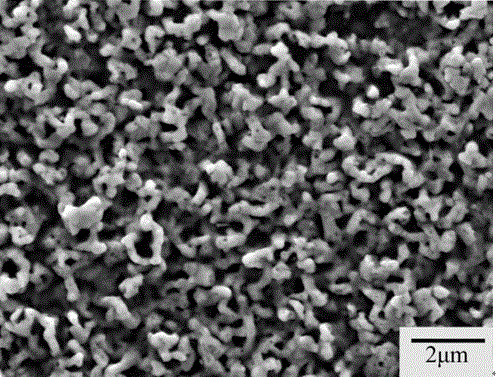

[0051] The scanned image of its surface is attached image 3 As shown, the cross-sectional scanning pictures are attached Figure 5 As shown, the friction coefficient curve is attached Figure 7 As shown, the wear scar cross-sectional profile of the sample after wear is shown in the attached Figure 9 As shown, the composition distribution curve of the section of the nitrided layer is shown in the attached Figure 11 As shown, the thickness of the nitriding layer is 7 μm, and the basic properties of the surface ion nitriding layer are shown in the attached Figure 13 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeable layer thickness | aaaaa | aaaaa |

| Permeable layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com