Atmospheric pressure glow plasma enhanced atom layer deposition device

A technology of atomic layer deposition and plasma, which is applied in the field of plasma technology and atomic layer deposition equipment, can solve problems such as difficult large-area discharge, achieve the effect of reducing costs, avoiding damage, and realizing continuous online mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

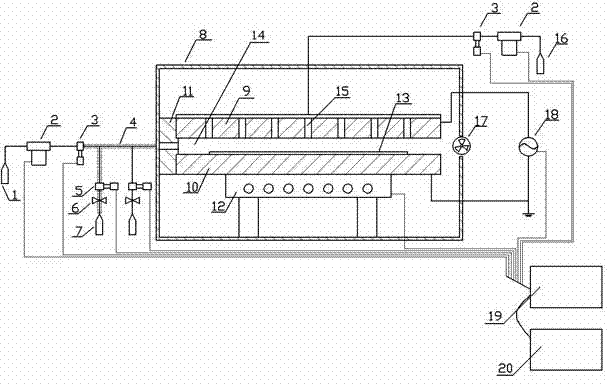

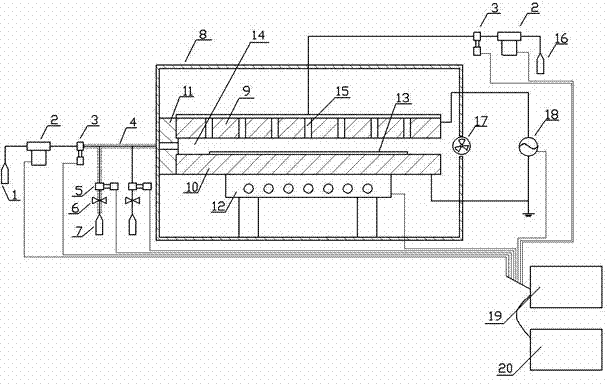

[0025] refer to figure 1 , an atmospheric pressure glow plasma enhanced atomic layer deposition device, including a relatively closed reaction chamber, the reaction chamber includes a main chamber 8, the main chamber 8 is provided with a precursor source inlet pipe port 11. The upper electrode 9 of the plasma generator and the lower electrode 10 of the plasma generator are directly opposite to each other. The sample 13 is placed on the lower electrode 10 of the plasma generator, and a heater 12 is arranged under the lower electrode 10 of the plasma generator. An air flow passage 14 is formed between the upper electrode 9 of the plasm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com