Diamond single crystal surface metallization treatment method

A diamond single crystal, surface metal technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of poor uniformity of single crystal surface roughness, lack of selectivity, single crystal etching, etc. , to achieve the effect of high surface roughness uniformity, simple process and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

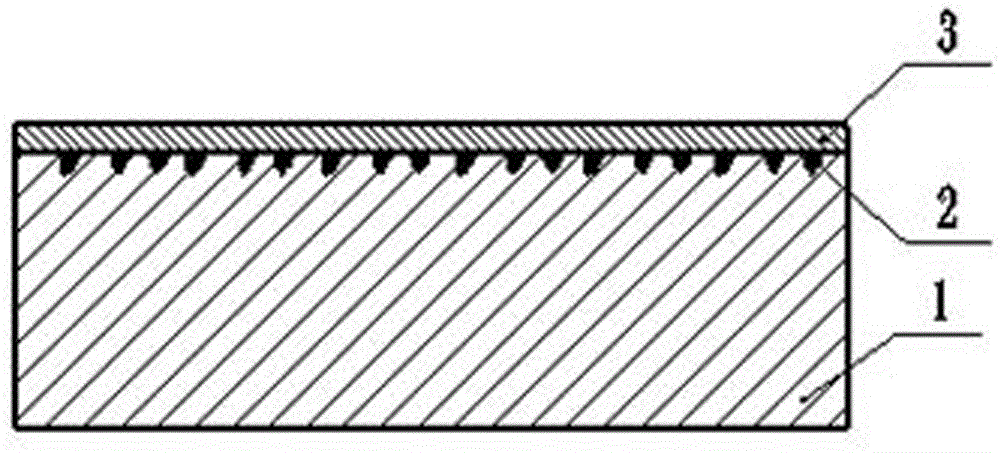

[0023] A method for metallizing the surface of a diamond single crystal, first using the double-glow plasma metallization technology, using the Fe target as the source, bombarding and sputtering the surface of the diamond single crystal, and then soaking the diamond single crystal with an acid solution to remove residual The metal and graphite; finally, using double-glow plasma metallization technology, using strong carbide metal W as a target to prepare a metal coating on the surface of diamond single crystal.

[0024] Among them, using the double-glow plasma metallization technology, using the Fe target as the source, bombarding and sputtering the surface of the diamond single crystal, and then soaking the single crystal in an acid solution to remove the residual metal and graphite process is as follows:

[0025] 1) Clean the diamond surface: ultrasonically clean the diamond single crystal produced by the high temperature and high pressure method with deionized water and alco...

Embodiment 2

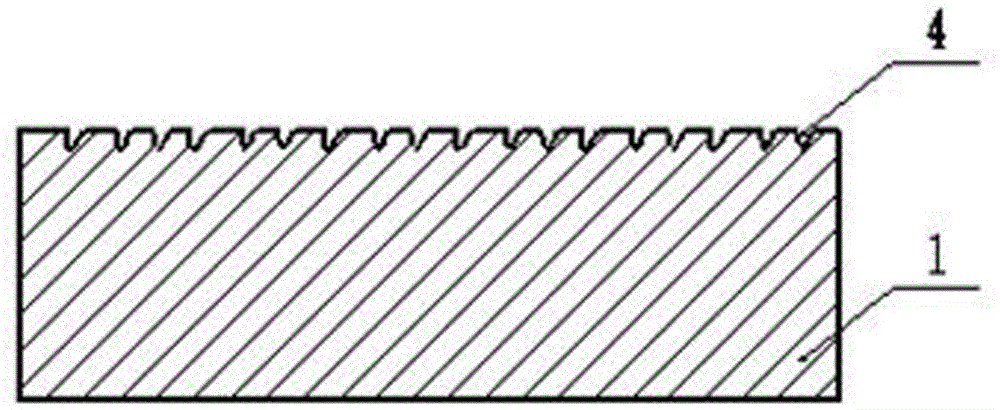

[0036] A method for metallizing the surface of diamond single crystals. First, double-glow plasma metallization technology is used to bombard and sputter the surface of diamond single crystals with Ni target material as the source, and then the diamond single crystals are soaked in acid solution to remove residual metal. As well as graphite, finally, using the double-glow plasma metallization technology, the metal coating is prepared on the surface of the diamond single crystal with the strong carbide metal Ti as the target.

[0037] Among them, using the double-glow plasma metallization technology, using the Ni target as the source, bombarding and sputtering the surface of the diamond single crystal, and then soaking the single crystal in an acid solution to remove the residual metal and graphite process is as follows:

[0038] 1) Cleaning the diamond surface: The diamond single crystal produced by chemical vapor deposition is ultrasonically cleaned with deionized water and al...

Embodiment 3

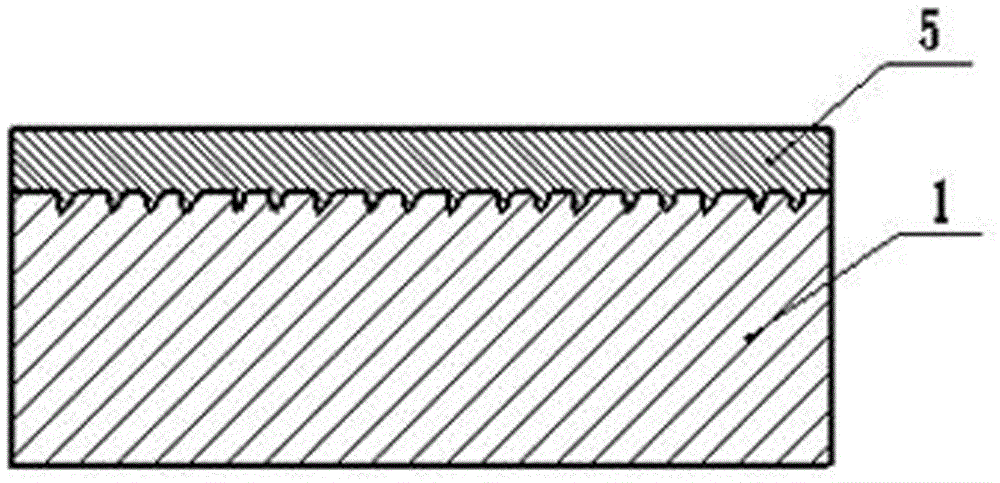

[0049] A method for metallizing the surface of a diamond single crystal, first using a double-glow plasma metallization technology, using a Co target as a source, bombarding and sputtering the surface of a diamond single crystal, and then using an acid solution to soak the single crystal to remove residual metal and Graphite, and finally use the double-glow plasma metallization technology to prepare a metal coating on the surface of the diamond single crystal with the strong carbide metal Hf as the target.

[0050] Among them, using the double-glow plasma metallization technology, using the Co target as the source, bombarding and sputtering the surface of the diamond single crystal, and then soaking the diamond single crystal in an acid solution to remove the residual metal and graphite process is as follows:

[0051] 1) Clean the diamond surface: ultrasonically clean the natural diamond single crystal with deionized water and alcohol, and dry it with hot air;

[0052] 2) Furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com