Production technology and formulation of microemulsion fuel oil

A production process and micro-emulsion technology, applied in the field of fuel oil, can solve problems such as not being perfect, achieve simple equipment, reduce operating temperature and noise, and reduce carbon deposits

Inactive Publication Date: 2003-04-16

季忠

View PDF0 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Petroleum is a non-renewable energy source. In order to save petroleum, there are currently many production processes and formulas for emulsified fuel oil and petroleum substitute fuels that have come out one after another. , chromaticity, etc., are not perfect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

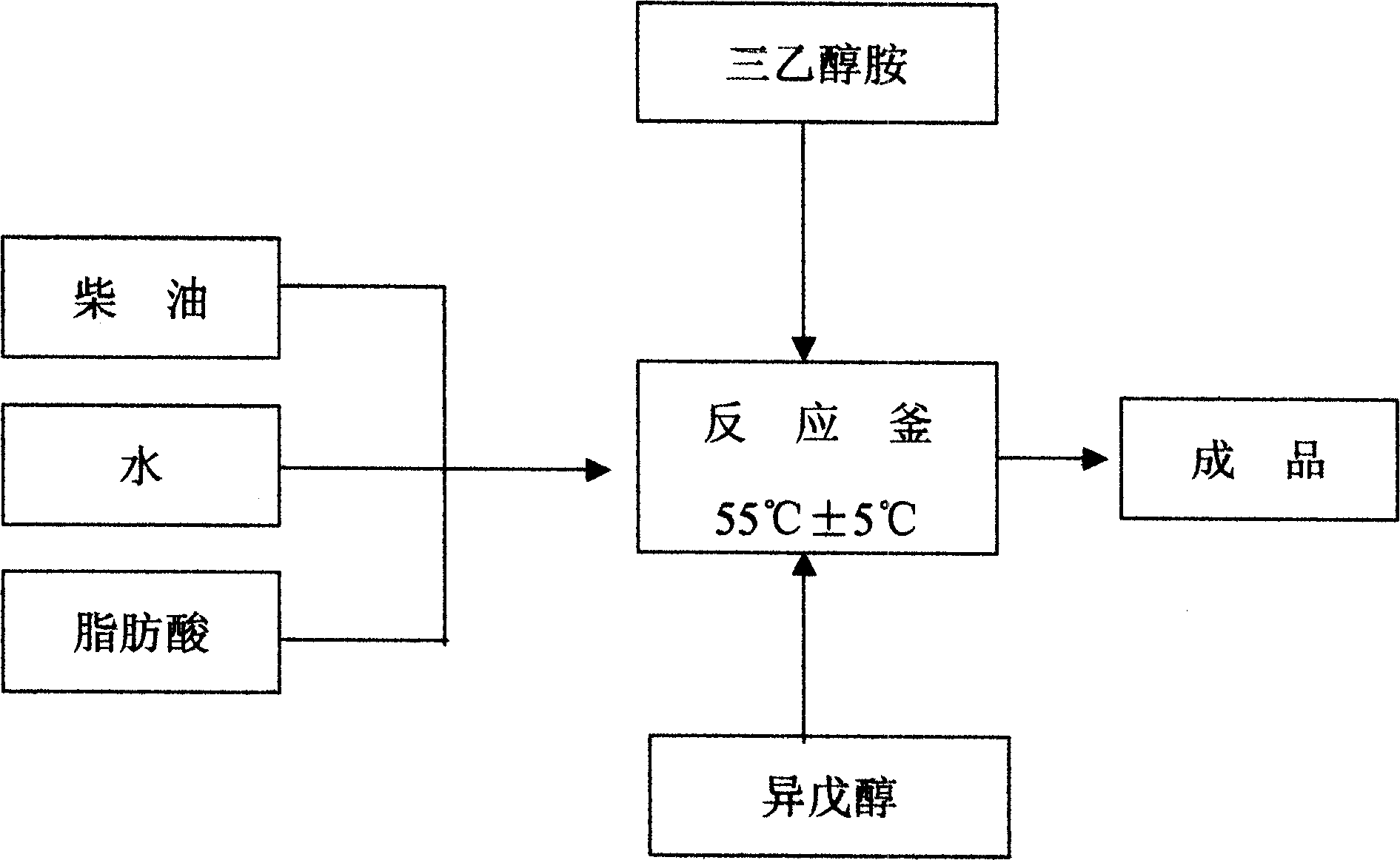

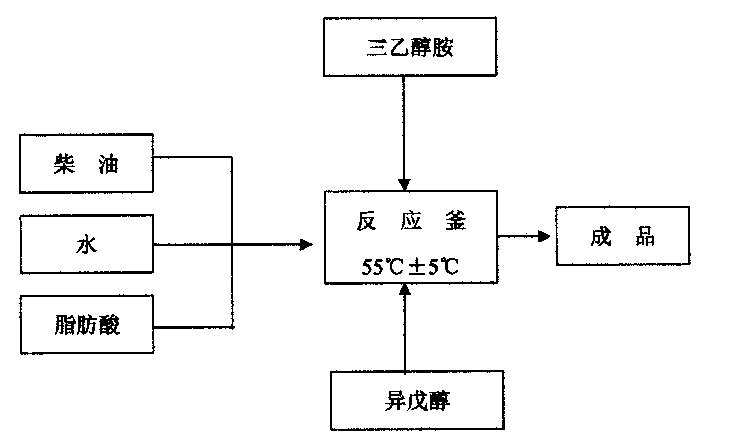

[0008] The production process of micro-emulsion fuel oil is to put diesel oil, water and fatty acid into the reactor at 50-60°C under normal pressure and mix and stir for about 10 minutes, then add triethanolamine and isoamyl alcohol, and stir for about 10 minutes. Finished product. According to the volume ratio, its best formula is: 20% water, 60% diesel oil, 15% fatty acid, 2% triethanolamine, and 3% isoamyl alcohol.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A microemulsified fuel oil is prepared from fatty acid (or oleic acid) (15 vol.%), triethanolamine (or biethanolamine) (2 vol.%), isopentanol (3 vol.%), water (20 vol.%) and diesel oil (60 vol.%). Its advantages are low cost, little harmful gas, and long service life of diesel engine.

Description

[0001] Field [0002] The invention belongs to the field of fuel oil, in particular to a production process and formula of emulsified fuel oil. Background technique [0003] Petroleum is a non-renewable energy source. In order to save petroleum, there are currently many production processes and formulas for emulsified fuel oil and petroleum substitute fuels that have come out one after another. , chroma, etc., are not perfect. After in-depth research, it is found that adding a large amount of surfactants and co-surfactants to the two-phase immiscible substances of oil and water can reduce the surface tension of oil and water to extremely low, and even drop to a negative value in an instant, making The whole system spontaneously forms a translucent or transparent isotropic liquid system, and water is dispersed in the oil as a dispersed phase to form a W / O microemulsion. The radius of the liquid droplets of this microemulsion is usually 10-100nm, and the thermodynamics is very ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G31/08

Inventor 季忠

Owner 季忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com