Aqueous polyurethane resin dispersion, manufacturing method for same, and paint composition containing same

A technology of water-based polyurethane and polyurethane prepolymer, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced storage stability, water-based polyurethane resin dispersion dispersibility and film-forming properties, and achieve stability Good, good film-forming properties, high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

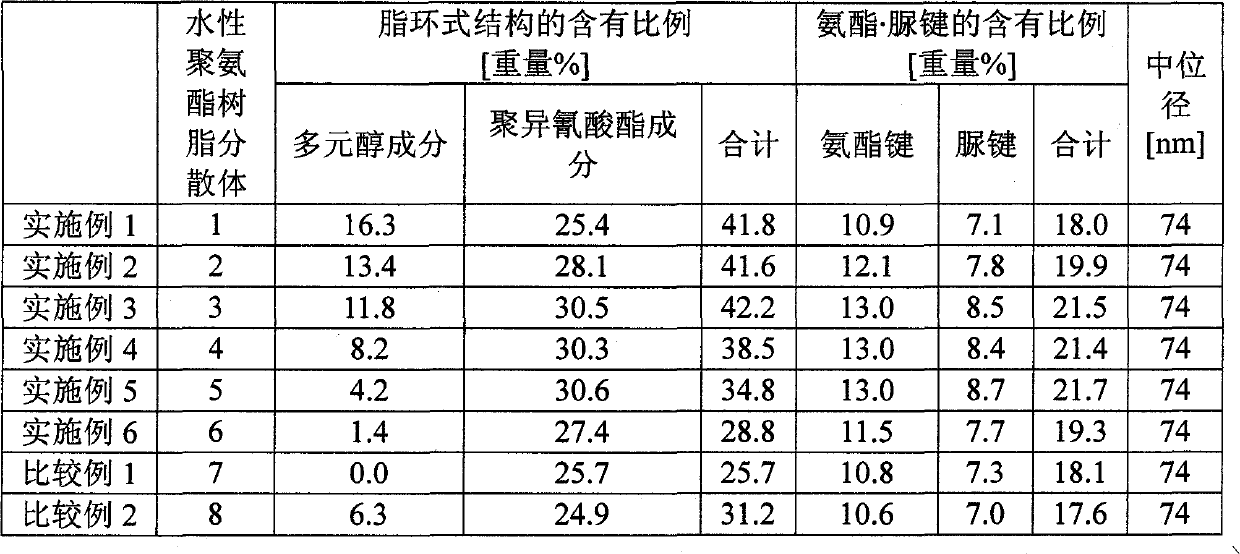

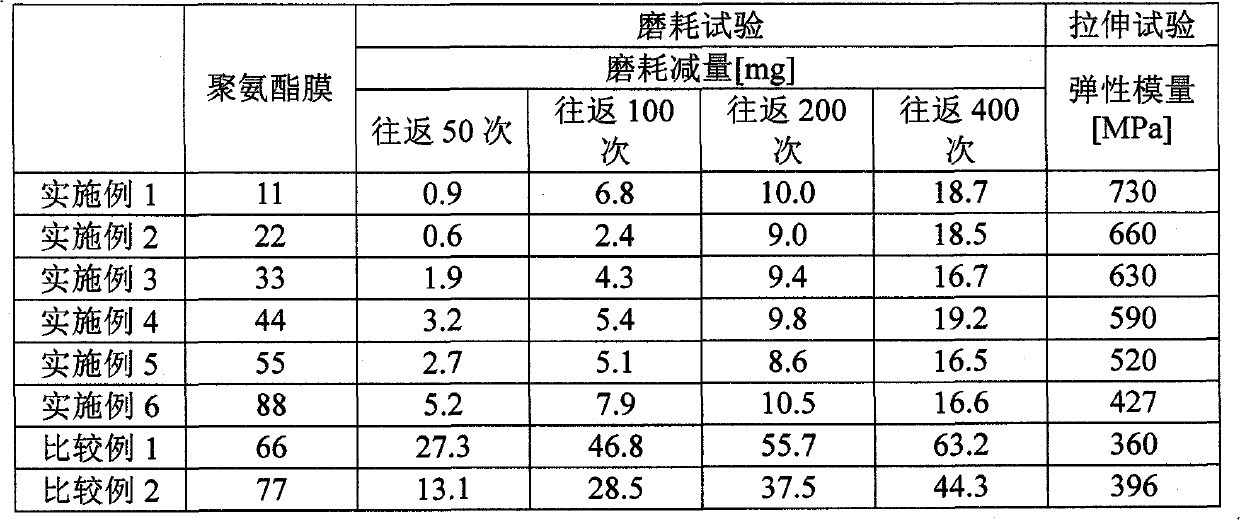

[0116] [Manufacture of water-based polyurethane resin dispersion (1)]

[0117]In a reaction vessel with a stirrer, a reflux condenser and a thermometer inserted, add ETERNACOLL UM90 (3 / 1) (polycarbonate diol manufactured by Ube Industries, Ltd.; number average molecular weight: 916; hydroxyl value: 122.5mgKOH) under nitrogen flow / g; polycarbonate diol obtained by reacting a polyol mixture with a molar ratio of 1,4-cyclohexanedimethanol:1,6-hexanediol=3:1 as a polyol component and carbonate) 1500g, 220g of 2,2-dimethylolpropionic acid (DMPA), and 1347g of N-methylpyrrolidone (NMP). It was then heated to 60°C to confirm the dissolution of DMPA. Add 4,4'-dicyclohexylmethane diisocyanate (hydrogenated MDI) 1445g, dibutyltin dilaurate (catalyst) 2.6g and heat to 90 ℃, carry out polyurethane reaction with 5 hours, obtain polyurethane prepolymer (at this time The carboxylic acid group content in the prepolymer was 2.38% by weight based on solid content). The NCO group content in ...

Embodiment 2

[0121] [Manufacture of water-based polyurethane resin dispersion (2)]

[0122] In the same reaction vessel as in Example 1, ETERNACOLLUM90 (3 / 1) (polycarbonate diol manufactured by Ube Industries, Ltd.; number average molecular weight 916; hydroxyl value 122.5 mgKOH / g; made as di 1,4-cyclohexanedimethanol:1,6-hexanediol=3:1 molar ratio polyol mixture and polycarbonate diol obtained by reacting polycarbonate diol) of alcohol component) 1267g, 1,4- 43.5 g of butanediol, 250 g of 2,2-dimethylolpropionic acid (DMPA), and 1368 g of N-methylpyrrolidone (NMP). It was then heated to 60°C to confirm the dissolution of DMPA. Add 4,4'-dicyclohexylmethane diisocyanate (hydrogenated MDI) 1640g, dibutyltin dilaurate (catalyst) 2.6g and heat to 90 ℃, carry out polyurethane reaction with 5 hours, obtain polyurethane prepolymer (at this time The carboxylic acid group content in the prepolymer was 2.66% by weight based on solid content). The NCO group content at the completion of the urethan...

Embodiment 3

[0126] [Manufacture of water-based polyurethane resin dispersion (3)]

[0127] In the same reaction vessel as in Example 1, ETERNACOLLUM90 (3 / 1) (polycarbonate diol manufactured by Ube Industries, Ltd.; number average molecular weight 916; hydroxyl value 122.5 mgKOH / g; made as di 1,4-cyclohexanedimethanol: 1,6-hexanediol=3:1 molar ratio polyol mixture and polycarbonate diol obtained by reaction of the alcohol component) 150 g, 1,4- 7.46 g of butanediol, 39.9 g of 2,2-dimethylolpropionic acid (DMPA), and 186 g of N-methylpyrrolidone (NMP). It was then heated to 60°C to confirm the dissolution of DMPA. Add 239 g of 4,4'-dicyclohexylmethane diisocyanate (hydrogenated MDI), 0.35 g of dibutyltin dilaurate (catalyst) and heat to 90° C., and carry out polyurethane reaction with 5 hours to obtain a polyurethane prepolymer (at this time The carboxylic acid group content in the prepolymer was 3.10% by weight based on solid content). The NCO group content at the completion of the uret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com