Polyethylene terephthalate resin composition and film formed therefrom

A technology of polyethylene terephthalate and resin composition, which is applied in the field of polyethylene terephthalate resin composition and films formed therefrom, can solve the problem that the gelation rate is reduced and cannot be obtained. Sufficient improvement, problems such as M/P, etc., to achieve the effect of less color change and oligomer generation, excellent electrostatic application castability, and less oligomer generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

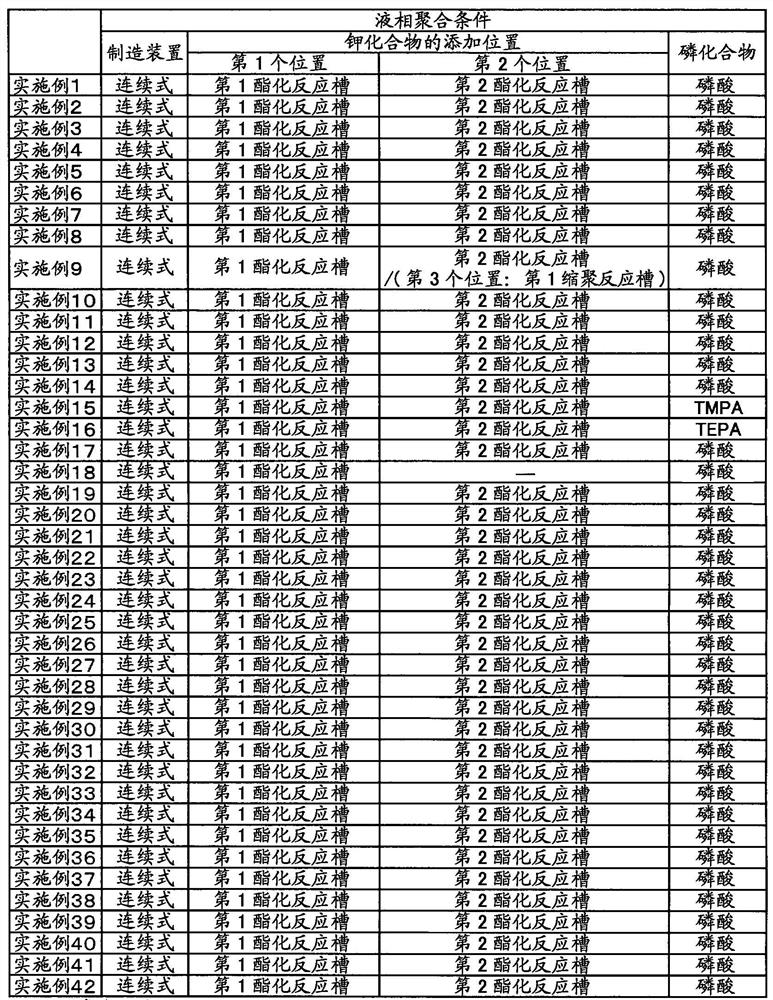

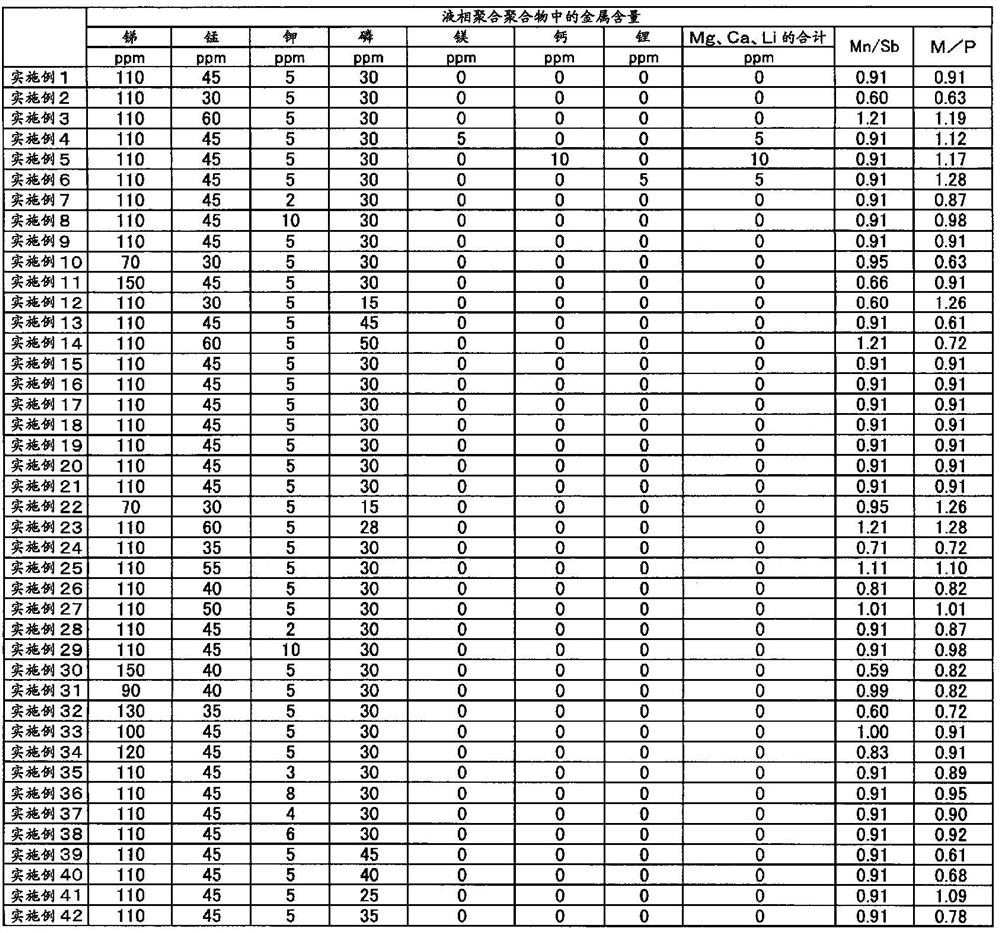

[0133]The one having all 5 tanks including the esterification reaction tank consisting of the first esterification reaction tank and the second esterification reaction tank, the first polycondensation reaction tank, the second polycondensation reaction tank, and the third polycondensation reaction tank following it is used Continuous polymerization unit. For the first esterification reaction tank, react at a reaction temperature of 240-255°C until the esterification reaction rate is 90-95%, and for the second esterification tank, react at a reaction temperature of 255°C until the esterification reaction rate is 90-95%. The conversion reaction rate is 97%, and the polycondensation reaction is performed at a temperature of 260°C in the first polycondensation reaction tank, at a temperature of 275°C in the second polycondensation reaction tank, and at a temperature of 280°C in the third esterification reaction tank, so as to achieve the target intrinsic viscosity Allow the reacti...

Embodiment 2、3

[0141] The amount of manganese acetate added so that the amount of metal contained in Table 2 was changed to 0.014% by weight (equivalent to 0.570 mol / t) and 0.028% by weight relative to the polyethylene terephthalate resin composition. % (corresponding to 1.14 mol / t), and the polyethylene terephthalate resin composition and film were obtained by the method similar to Example 1 except this. Although the gelation ratio of the polyethylene terephthalate resin composition increased by changing the amount of manganese acetate added, it was at a level that did not pose a problem. In Example 3, although the turbidity of the solution increased due to the increase in the amount of the manganese element, the film defect was at a level without any problem.

Embodiment 4~6

[0143] 0.0046% by weight (equivalent to 0.214 mol / t) of magnesium acetate, 0.00045% by weight (corresponding to 0.059mol / t) of calcium acetate, 0.0075% by weight (corresponding to 0.735mol / t) of lithium acetate, except that, obtain polyethylene terephthalate by the same method as in Example 1 Alcohol ester resin compositions and films. In Examples 4, 5, and 6, due to the addition of a highly active metal catalyst, the gelation rate of the polyethylene terephthalate resin composition increased, and the amount of production of linear oligomers also increased, but Membrane defects were at a non-problematic level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com