Leakage-proof air-flue gaseous ring

A gas ring and airway technology, applied to piston rings, engine components, machines/engines, etc., can solve problems such as increased oil consumption, enlarged end clearance, and increased high-speed jet flow, so as to improve the average effective pressure and Thermal efficiency, elimination of high-speed jet effect, and reduction of oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

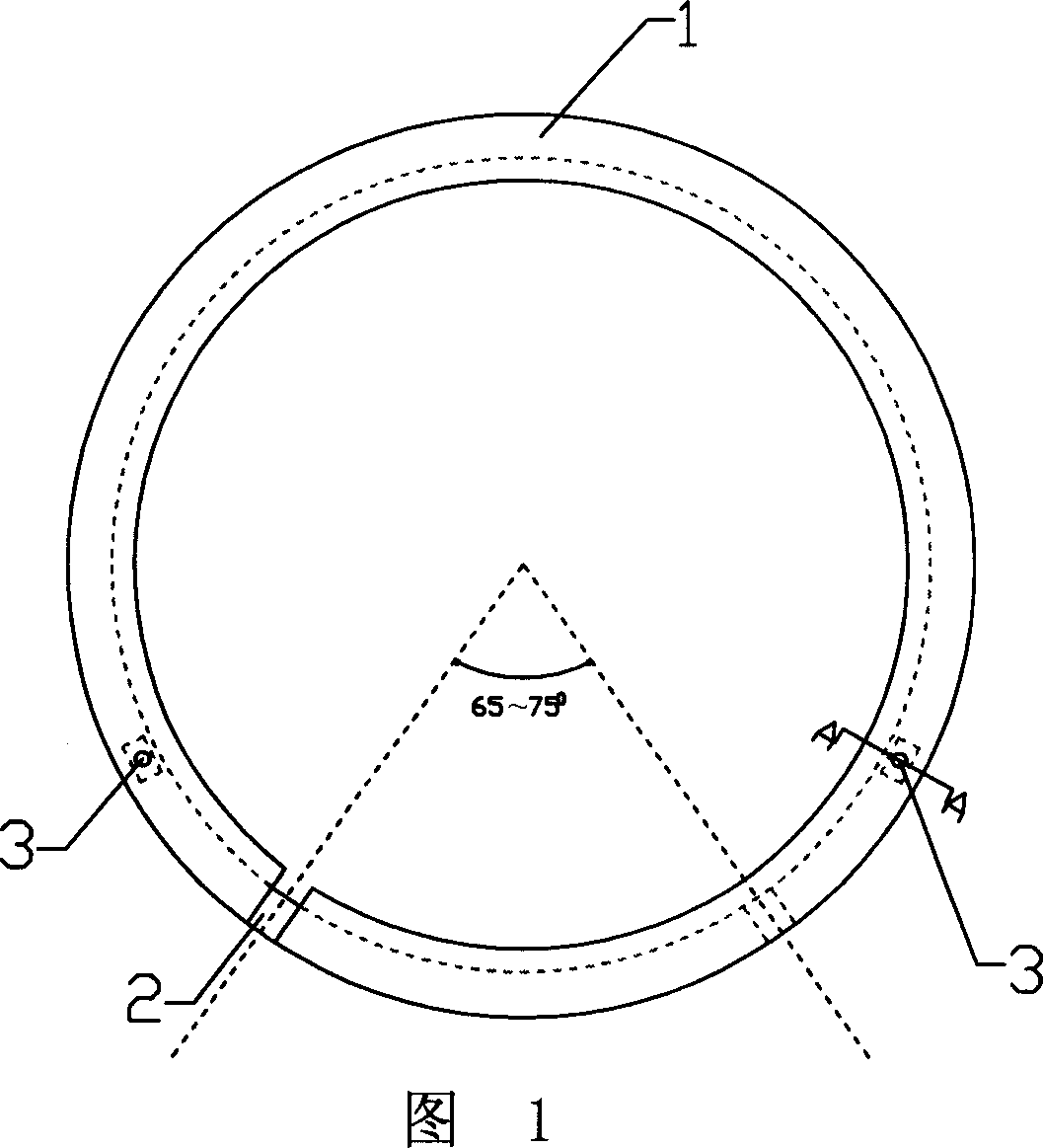

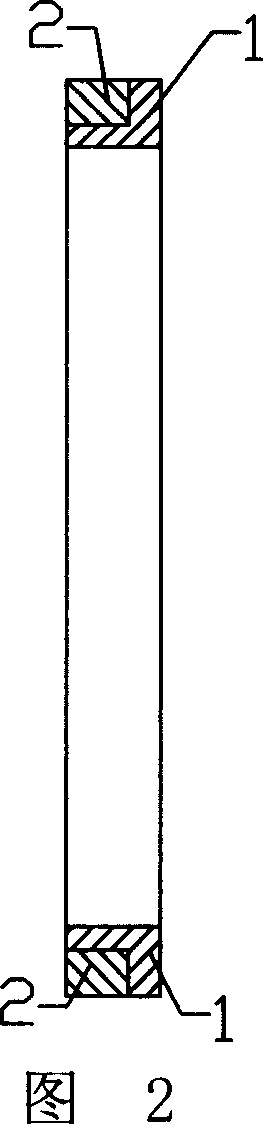

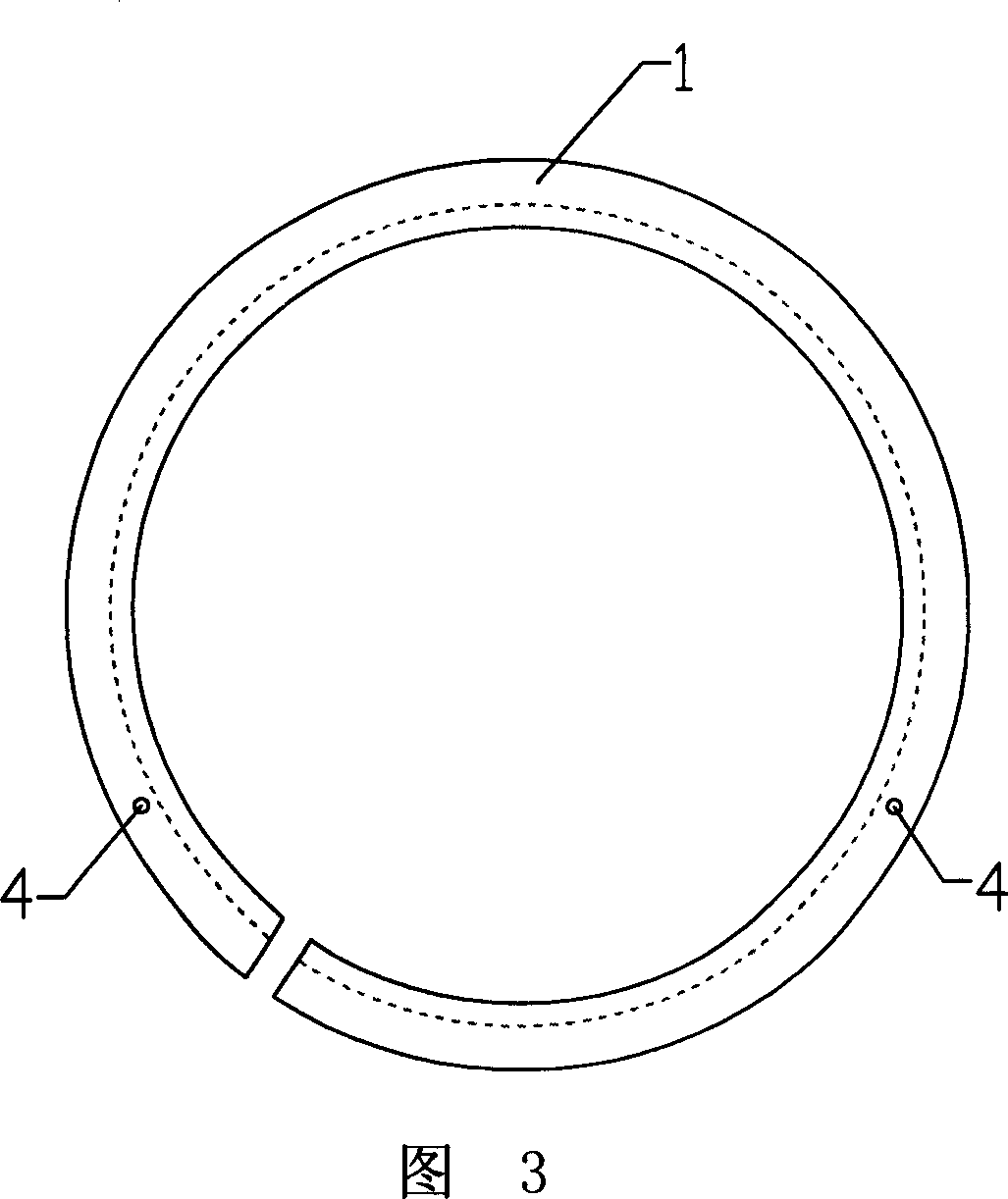

[0028] Embodiment 1, as shown in Fig. 1 and Fig. 2, a non-leakage air passage gas ring is used for sealing between the internal combustion engine piston and the cylinder block, and the non-leakage air passage air ring includes an upper ring 1 combined into one and the lower ring 2, as shown in Figure 3 and Figure 4, the section of the upper ring 1 is L-shaped, as shown in Figure 5 and Figure 6, the section of the lower ring 2 is rectangular, the upper ring 1 and the lower The rings 2 have openings respectively. The openings of the upper ring 1 and the lower ring 2 are set at an angle of 68°. The outer peripheries of the upper ring 1 and the lower ring 2 are closely matched and are on the same circumferential surface. The lower bottom surfaces of the rings 2 are closely matched and are on the same plane. Since the openings of the upper and lower rings are staggered and blocked from each other, the air leakage path is eradicated, the amount of air leakage is reduced, and the aver...

Embodiment 2

[0030] Embodiment 2, as shown in Fig. 1 and Fig. 2, a non-leakage air passage gas ring is used for sealing between the piston and the cylinder block of an internal combustion engine, and the non-leakage air passage air ring includes an upper ring 1 combined and the lower ring 2, as shown in Figure 3 and Figure 4, the section of the upper ring 1 is L-shaped, as shown in Figure 5 and Figure 6, the section of the lower ring 2 is rectangular, the upper ring 1 and the lower The rings 2 have openings respectively. The openings of the upper ring 1 and the lower ring 2 are set at an angle of 73°. The outer peripheries of the upper ring 1 and the lower ring 2 are closely matched and are on the same circumferential surface. The lower bottom surfaces of the rings 2 are closely matched and are on the same plane. Since the openings of the upper and lower rings are staggered and blocked from each other, the air leakage path is eradicated, the amount of air leakage is reduced, and the average...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com