Long glass fiber enhanced polypropylene composite material water meter casing and manufacture method thereof

A long glass fiber and composite material technology, which is applied in the field of long glass fiber reinforced polypropylene composite water meter housing and production, can solve the problems of polluting the environment, serious toxicity of chromium compounds, endangering human health, etc., and achieves acid and alkali resistance. Good properties, high dimensional stability, good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

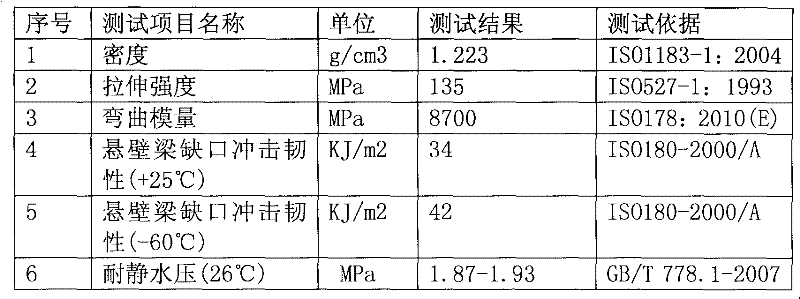

Embodiment 1

[0037] In a long glass fiber reinforced polypropylene composite water meter shell material: glass fiber accounts for 42% by weight, the length of glass fiber is 12mm, polypropylene accounts for 53% by weight, and the toughening agent POE accounts for 1% by weight %, the compatibilizer maleic anhydride graft accounts for 1% by weight, the toner accounts for 1% by weight, the antioxidant (1010 and 168) accounts for 1% by weight, and the anti-ultraviolet absorber accounts for 1% by weight 1%.

[0038] The blend alloy composed of continuous glass fiber, polypropylene and / or modified polypropylene, additives, toner, antioxidant and anti-ultraviolet light absorber are uniformly mixed with each other according to a certain weight ratio, and then passed through an extruder After melting and mixing, the strands were made, and the pellets with a length of 12 mm were cut to form the final blend composite material. The blend is heated and melted by the injection molding machine at a temper...

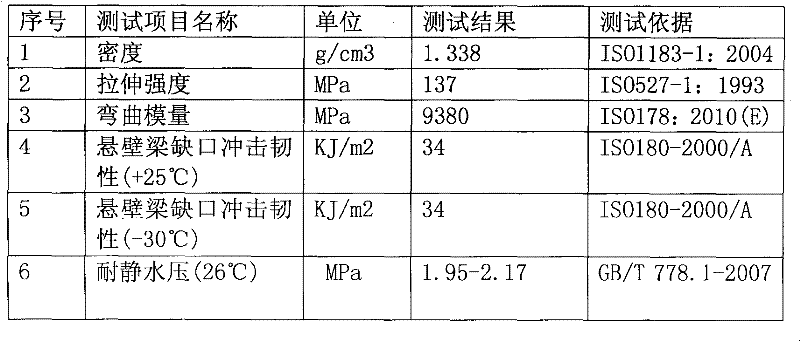

Embodiment 2

[0043] In a long glass fiber reinforced polypropylene composite water meter shell material: the glass fiber accounts for 45% by weight, and the length of the glass fiber is 13mm. Polypropylene accounted for 49% by weight, toughening agent POE accounted for 1% by weight, compatibilizer maleic anhydride graft accounted for 2% by weight, toner accounted for 1% by weight, antioxidant (1010 and 168) account for 1% by weight, and the anti-ultraviolet light absorbing agent accounts for 1% by weight.

[0044] The blend alloy composed of continuous glass fiber, polypropylene and / or modified polypropylene, additives, toner, antioxidant and anti-ultraviolet light absorber are uniformly mixed with each other according to a certain weight ratio, and then passed through an extruder After melting and mixing, the strands were made and cut into pellets with a length of 13 mm to form the final blend composite material. The blend is heated and melted by the injection molding machine at a temper...

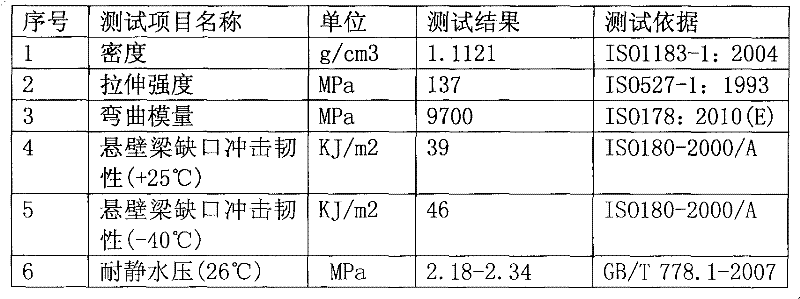

Embodiment 3

[0049] In a long glass fiber reinforced polypropylene composite water meter shell material: glass fiber accounts for 54% by weight, the length of glass fiber is 12mm, polypropylene accounts for 40% by weight, and the toughening agent POE accounts for 1% by weight %, the compatibilizer maleic anhydride graft accounts for 2% by weight, the toner accounts for 1% by weight, the antioxidant (1010 and 168) accounts for 1% by weight, and the anti-ultraviolet absorber accounts for 1% by weight 1%.

[0050] The blend alloy composed of continuous glass fiber, polypropylene and / or modified polypropylene, additives, toner, antioxidant and anti-ultraviolet light absorber are uniformly mixed with each other according to a certain weight ratio, and then passed through an extruder After melting and mixing, the strands were made, and the pellets with a length of 12 mm were cut to form the final blend composite material. The blend is heated and melted by the injection molding machine at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com