Aqueous polyurethane resin dispersion, manufacturing method thereof, and paint composition containing the same

一种水性聚氨酯、聚氨酯树脂的技术,应用在聚脲/聚氨酯涂料、涂层等方向,能够解决水系介质分散性变差、涂膜硬度的影响不清楚、涂布剂领域不充分等问题,达到耐磨性优异、硬度优异、分散稳定性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

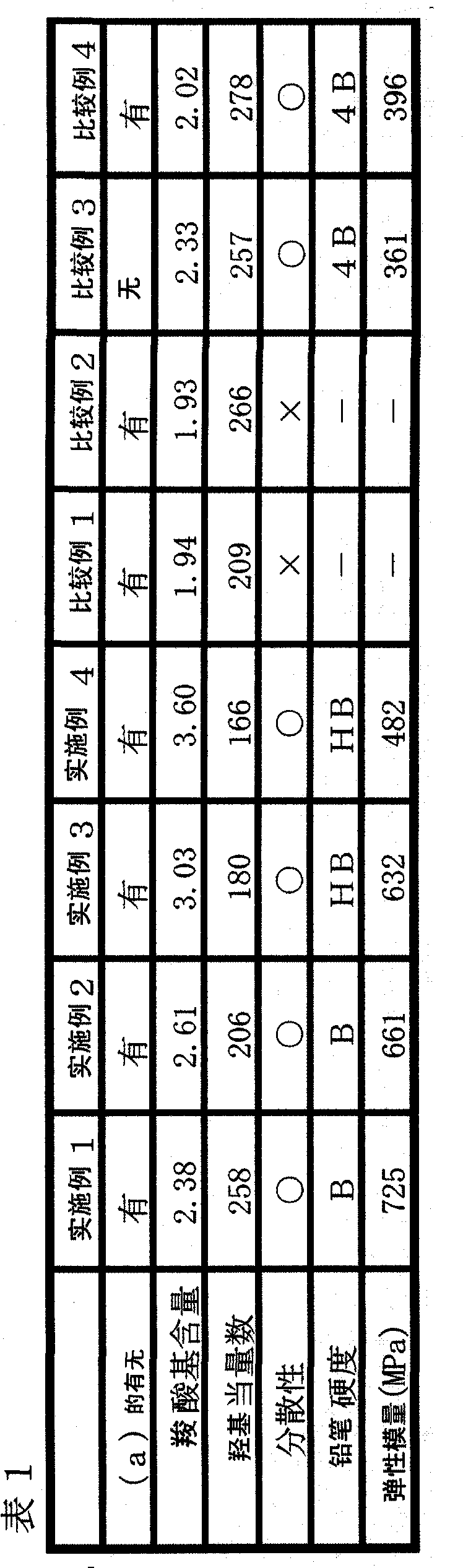

Embodiment 1

[0139] (Manufacture of polycarbonate polyol (a) having an alicyclic structure in the main chain)

[0140] 271.6 parts by weight of 1,6-hexanediol, 893.2 parts by weight of 1,4-cyclohexanedimethanol, 847.0 parts by weight of dimethyl carbonate and 0.15 parts by weight of tetra-n-butoxytitanium are charged into a device equipped with a stirrer, a thermometer and In the reactor of the fractionation tube, the by-produced methanol and dimethyl carbonate were reacted under the condition of 95-160°C while azeotroping. After almost no methanol was distilled off, the pressure was reduced to 10 mmHg or less, and the reaction was further made for 4 hours. It should be noted that the reaction was carried out under a nitrogen atmosphere. After completion of the reaction, the reaction liquid was cooled to obtain a colorless and transparent liquid at room temperature with a hydroxyl value of 124.7 (number average molecular weight: 900).

[0141] (Manufacture of water-based polyurethane res...

Embodiment 2

[0144] (Manufacture of water-based polyurethane resin dispersion)

[0145]180.8 parts by weight of the polycarbonate polyol (a) having an alicyclic structure in the main chain produced in Example 1, 36.4 parts by weight of 2,2-dimethylol propionic acid, and 6.4 parts by weight of 1,4-butanediol part and 195.0 parts by weight of NMP (N-methyl-2-pyrrolidone) were introduced into a reaction device equipped with a stirrer and a heater while introducing nitrogen gas. Then, it was heated to 60° C., and it was confirmed that the dimethylolpropionic acid was dissolved. Then add 244.0 parts by weight of hydrogenated MDI, 0.4 parts by weight of dibutyltin dilaurate as a catalyst, heat to 90°C, and carry out urethanization reaction in 5 hours to manufacture polyurethane prepolymer (carboxylic acid in polyurethane prepolymer The radical content was 2.61% by weight, and the total number of hydroxyl equivalents of the polyol components was 206). The NCO group content at the end of the ure...

Embodiment 3

[0147] (Manufacture of water-based polyurethane resin dispersion)

[0148] 180.0 parts by weight of polycarbonate polyol (a), 48.1 parts by weight of 2,2-dimethylolpropionic acid, and 8.9 parts by weight of 1,4-butanediol, produced in Example 1 part and 223.8 parts by weight of NMP (N-methyl-2-pyrrolidone) were introduced into a reaction device equipped with a stirrer and a heater while introducing nitrogen gas. Then, it was heated to 60° C., and it was confirmed that the dimethylolpropionic acid was dissolved. Then add 296.3 parts by weight of hydrogenated MDI, 0.4 parts by weight of dibutyltin dilaurate as a catalyst, heat to 90°C, and carry out urethanization reaction in 5 hours to manufacture polyurethane prepolymer (carboxylic acid in polyurethane prepolymer The radical content is 3.03% by weight, and the total number of hydroxyl equivalents of the polyol components is 180). The NCO group content at the end of the urethanization reaction was 5.20% by weight. The reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com