Waterborne polyurethane emulsion, preparation method and impregnated gloves

A water-based polyurethane and polyurethane technology, which is applied in the field of polymer polyurethane emulsion preparation, can solve the problem of affecting the quality and service life of water-based polyurethane coated gloves, hindering the innovative development and popularization of water-based polyurethane dipped gloves, and the water resistance of water-based polyurethane dipped gloves. It can reduce the problems of poor wear resistance and wear resistance, and achieve the effect of saving processing and production costs, low potential energy, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

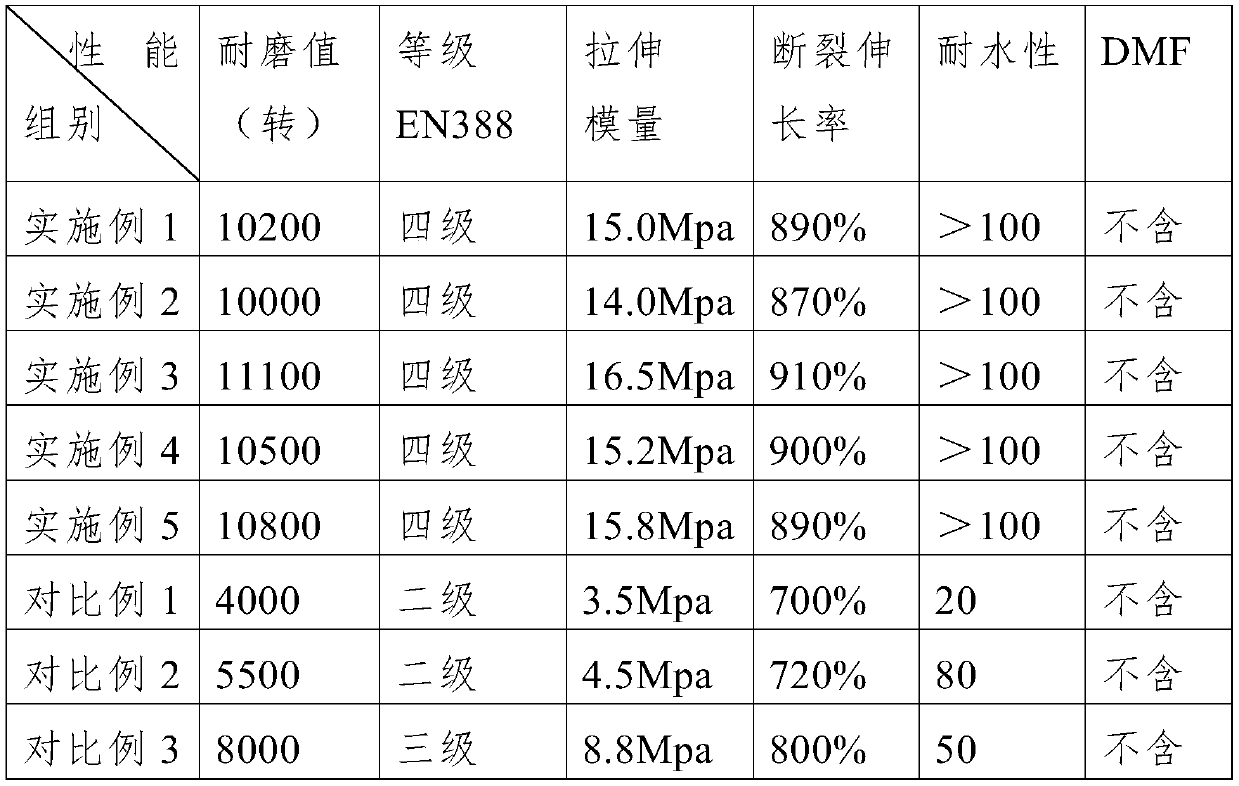

Examples

Embodiment 1

[0052] The present embodiment prepares a modified water-based polyurethane dipped glove, comprising steps:

[0053] S1: add 10 parts by mass of dehydrated hydroxyl-terminated polydimethylsiloxane diol and 40 parts by mass of polyethylene adipate, 10 parts by mass of toluene diisocyanate and 0.5 parts by mass of stannous octoate into the container , stir evenly at 60°C for 2h, then add 2 parts by mass of chain extender sodium ethylenediaminoethanesulfonate, continue to react at 50°C for 2h, then add 30 parts by mass of acetone to reduce the viscosity, and add 0.5 parts by mass of trisulfate. Ethylamine was neutralized, and the reaction was continued at 60 °C for 1 h until the content of isocyanate group-NCO was constant, and the temperature was lowered to obtain a polyurethane prepolymer.

[0054] S2: then add the polyurethane prepolymer to 120 mL of 2 parts by mass of sodium ethylenediamine ethanesulfonate and 1 part by mass of epoxy group-modified silica sol for emulsificatio...

Embodiment 2

[0057] In this example, on the basis of Example 1, the reactive silicone is selected as "alkoxy-terminated polydimethylsiloxane", the types of isocyanates, catalysts, and modified silicon nanoparticles are changed, and the types of The amount of raw materials used.

[0058] The present embodiment prepares a modified water-based polyurethane dipped glove, comprising the steps:

[0059] S1: 8 parts by mass of dehydrated alkoxy-terminated polydimethylsiloxane and 40 parts by mass of polytrimethylene adipate polyol, 7 parts by mass of diphenylmethane diisocyanate and 0.5 parts by mass of N-ethyl methacrylate Add linoline to the container, stir evenly at 70°C for 2h, then add 2 parts by mass of chain extender 1,4-cyclohexanediol, continue to react at 70°C for 2h, then add 30 parts by mass of acetone to reduce viscosity, and add 0.5 parts by mass of ethanolamine was neutralized, the reaction was continued at 70° C. for 1 h until the content of isocyanate group-NCO was constant, and...

Embodiment 3

[0063] In this example, on the basis of Example 1, the reactive silicone is selected as "polyether hydroxyl terminated polydimethylsiloxane", the types of isocyanates, catalysts, and modified silicon nanoparticles are changed and fine-tuned The amount of each raw material.

[0064] The present embodiment prepares a modified water-based polyurethane dipped glove, comprising the steps:

[0065] S1: 9 parts by mass of dehydrated polyether hydroxyl terminated polydimethylsiloxane and 35 parts by mass of polytrimethylene adipate polyol, 12 parts by mass of 1,6-hexamethylene diisocyanate and 0.5 parts by mass of dilauric acid Dibutyltin was added to the container, stirred evenly and reacted at 50°C for 2h, then added 2 parts by mass of 1,4-butanediol, continued to react at 50°C for 2h, then added 25 parts by mass of acetone to reduce viscosity, and added 0.5 part by mass Triethylamine was neutralized, and the reaction was continued at 60° C. for 1 h until the isocyanate group conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com