Fluid active lime powder with low surface energy and production method thereof

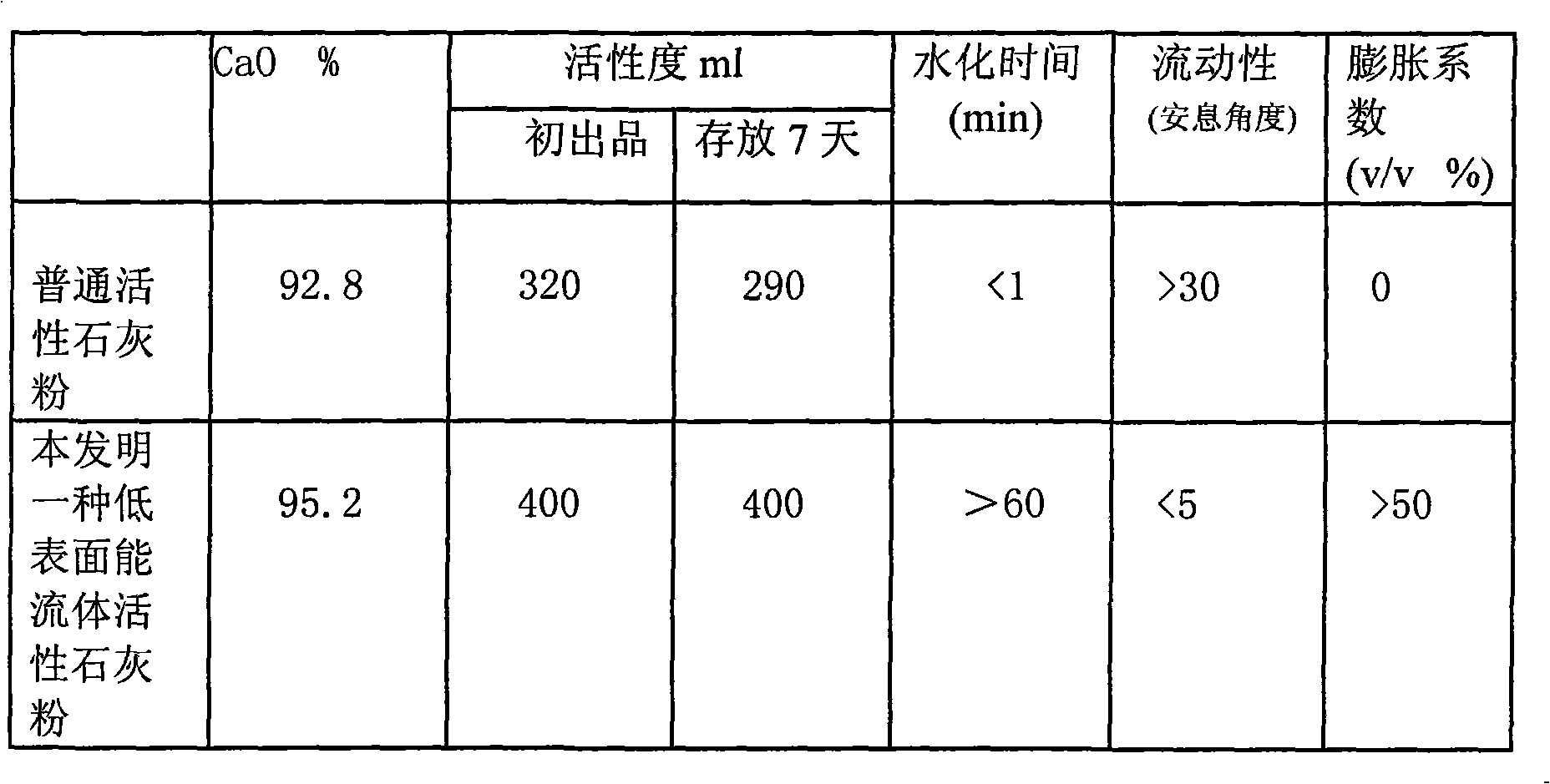

A low surface energy, lime powder technology, applied in the field of low surface energy fluid active lime powder and its production, can solve the problems of high production conditions, low production conditions, long calcination time, etc., and achieve resource saving and high activity , the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A low surface energy fluid active lime powder, including lime powder and a modifier, the weight ratio of the lime powder and the modifier is: 100:0.5, and the composition and weight ratio of the modifier are: chromium trioxide 45, 95% ethanol solution 95, soap powder 21, 40% potassium hydroxide solution 51, calcium oxide 100, silicone oil 71.

[0044] A method for producing the above-mentioned low-surface-energy fluid active lime powder, the production steps are: selecting limestone, kiln-calcining, crushing, mixing the above-mentioned improver, fine grinding and storing;

[0045] The step of selecting limestone refers to: select limestone of 50mm-100mm to wash with water, dry and install in a kiln;

[0046] The calcination step refers to: the temperature of calcination after kiln installation is 1150°C-1250°C, and the time is 2-2.5 hours;

[0047] The crushing step refers to: crushing the calcined lime, the particle size is less than 20mm;

[0048] Said mixing the ab...

Embodiment 2

[0051] A low surface energy fluid active lime powder, including lime powder and a modifier, the weight ratio of the lime powder and the modifier is: 100:0.7, and the composition and weight ratio of the modifier are: chromium trioxide 60, 96% ethanol solution 110, soap powder 30, 50% sodium hydroxide solution 5.8, calcium carbonate 100, silicone oil 10.

[0052] A method for producing the above-mentioned low-surface-energy fluid active lime powder, the production steps are: selecting limestone, kiln-calcining, crushing, mixing the above-mentioned improver, fine grinding and storing;

[0053] The step of selecting limestone refers to: select limestone of 50mm-100mm to wash with water, dry and install in a kiln;

[0054] The calcination step refers to: the temperature of calcination after kiln installation is 1150°C-1250°C, and the time is 2-2.5 hours;

[0055] The crushing step refers to: crushing the calcined lime, the particle size is less than 20mm;

[0056] Said mixing the...

Embodiment 3

[0059] A low surface energy fluid active lime powder, including lime powder and a modifier, the weight ratio of the lime powder and the modifier is: 100:0.6, and the composition and weight ratio of the modifier are: chromium trichloride 53 , 99% ethanol solution 100, soap powder 24, 30% sodium hydroxide solution 5.7, polyethylene paraffin 100, silicone oil 9.

[0060]A method for producing the above-mentioned low-surface-energy fluid active lime powder, the production steps are: selecting limestone, kiln-calcining, crushing, mixing the above-mentioned improver, fine grinding and storing;

[0061] The step of selecting limestone refers to: select limestone of 50mm-100mm to wash with water, dry and install in a kiln;

[0062] The calcination step refers to: the temperature of calcination after kiln installation is 1150°C-1250°C, and the time is 2-2.5 hours;

[0063] The crushing step refers to: crushing the calcined lime, the particle size is less than 20mm;

[0064] Said mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com