Composite silicate fire partition

A composite silicate and adhesive technology, which is applied in fire protection, building components, heat preservation, etc., can solve the problems of lack of fire protection effect, easy deformation and collapse, and difficult push-pull movement, etc., and achieves simple structure and good sound-absorbing performance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

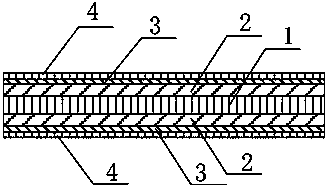

[0012] Example 1: see figure 1 , a composite silicate fireproof partition, including a metal mesh frame 1 welded by criss-cross metal rods, the front and back of the frame 1 are bonded by an adhesive to a composite silicate hard insulation Insulation board 2, the composite silicate hard thermal insulation board 2 is provided with a decorative panel 4 on the side away from the frame 1, and the composite silicate hard thermal insulation board 2 and the decorative panel 4 are provided with glass fiber The cloth layer 3, the veneer 4 is pressed from SMC composite material.

[0013] The metal mesh frame 1 welded by criss-cross metal rods is used as a support as a whole, which is not easy to deform, collapse, and has high strength. The composite silicate hard thermal insulation board 2 is an inorganic material, which has low thermal conductivity, non-combustibility, and high strength. , has good heat insulation and fire resistance, the glass fiber cloth layer 3 is well formed, has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com